Control system for a functional section of a paper processing device

A paper processing device and control system technology, applied in general control systems, control/regulation systems, papermaking safety devices, etc., can solve problems such as poor protocols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Identical or similar components in different figures bear the same reference numerals. Labeling in the figure is schematic.

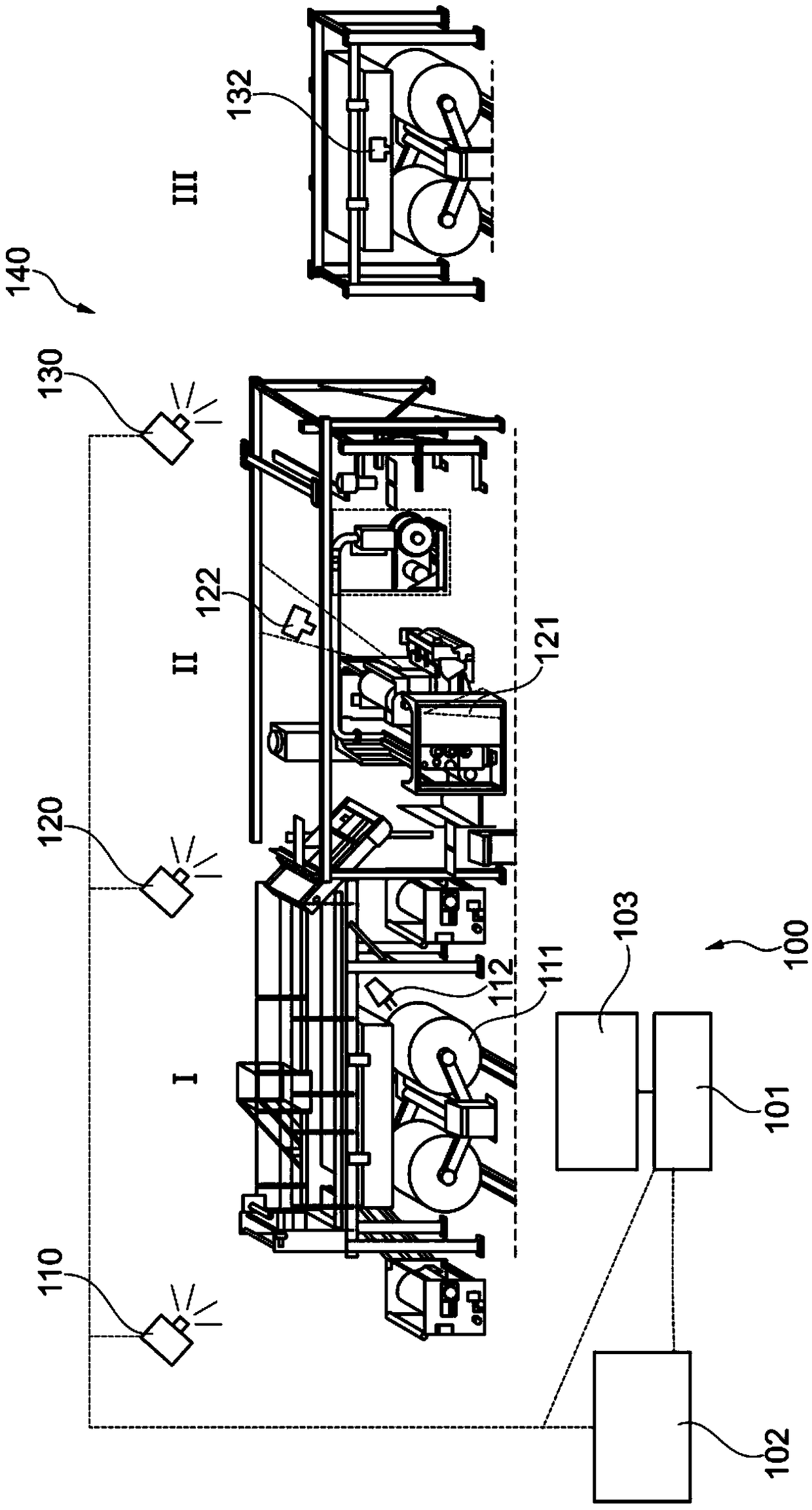

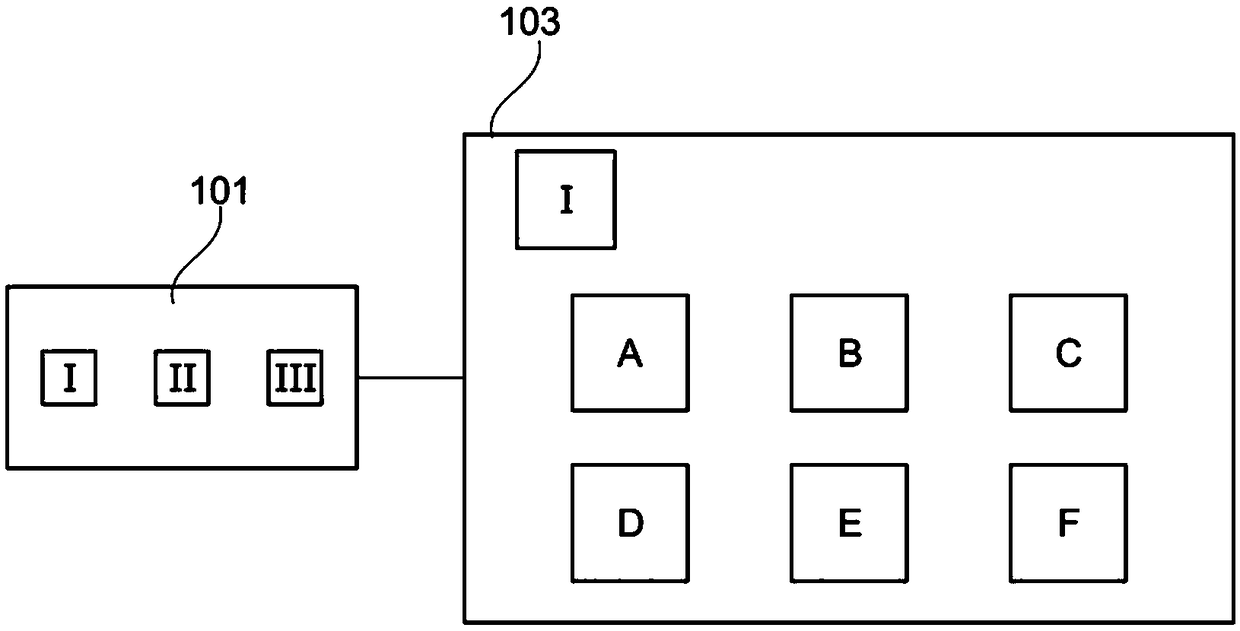

[0036] figure 1 The control system 100 for the functional parts I, II, III of the sheet handling device 140 is shown. The control system 100 has at least one security monitoring camera 110 , 120 , 130 arranged in the functional parts I, II, III, so that functional areas of the functional parts I, II, III can be captured by the security monitoring cameras 110 , 120 , 130 . The operating unit 101 of the system 100 is designed to operate the functional parts I, II, III. The image data of at least one security surveillance camera 110 , 120 , 130 can be selected using the operating unit 101 . The display unit 103 is configured to display the selected image data so that the user permits or blocks the operation of the functional parts I, II, III based on the displayed image data.

[0037] Furthermore, a security device 102 connected to the security ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com