Turning lathe grinding workpiece device

A lathe and grinding technology, which is applied in the direction of grinding/polishing safety devices, grinding machine parts, devices for fixing grinding wheels, etc., which can solve the problems of enterprise loss, failure to grind circumferential grooves, failure to meet roughness requirements, etc. , to achieve the effect of convenient use, simple operation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

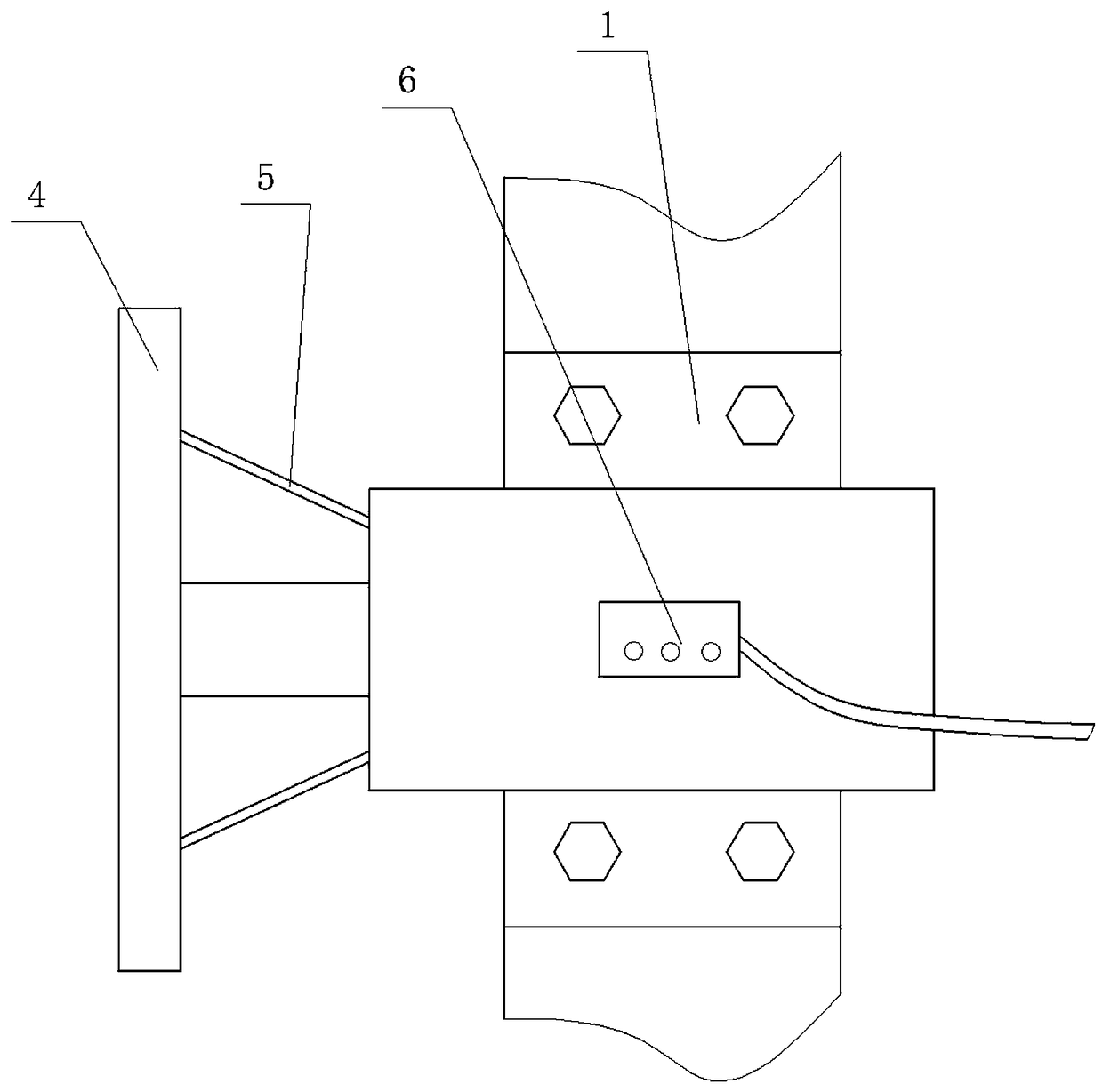

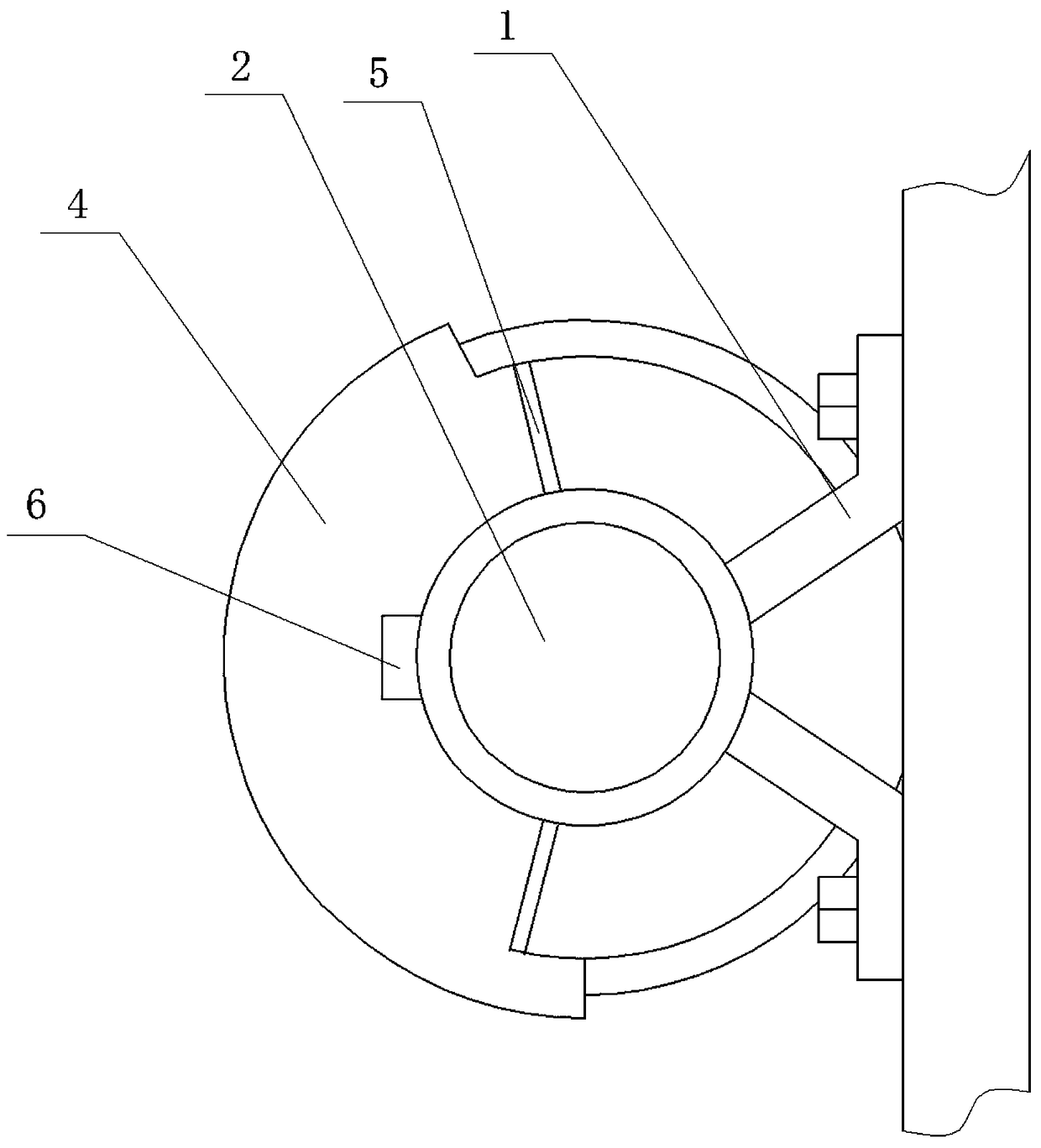

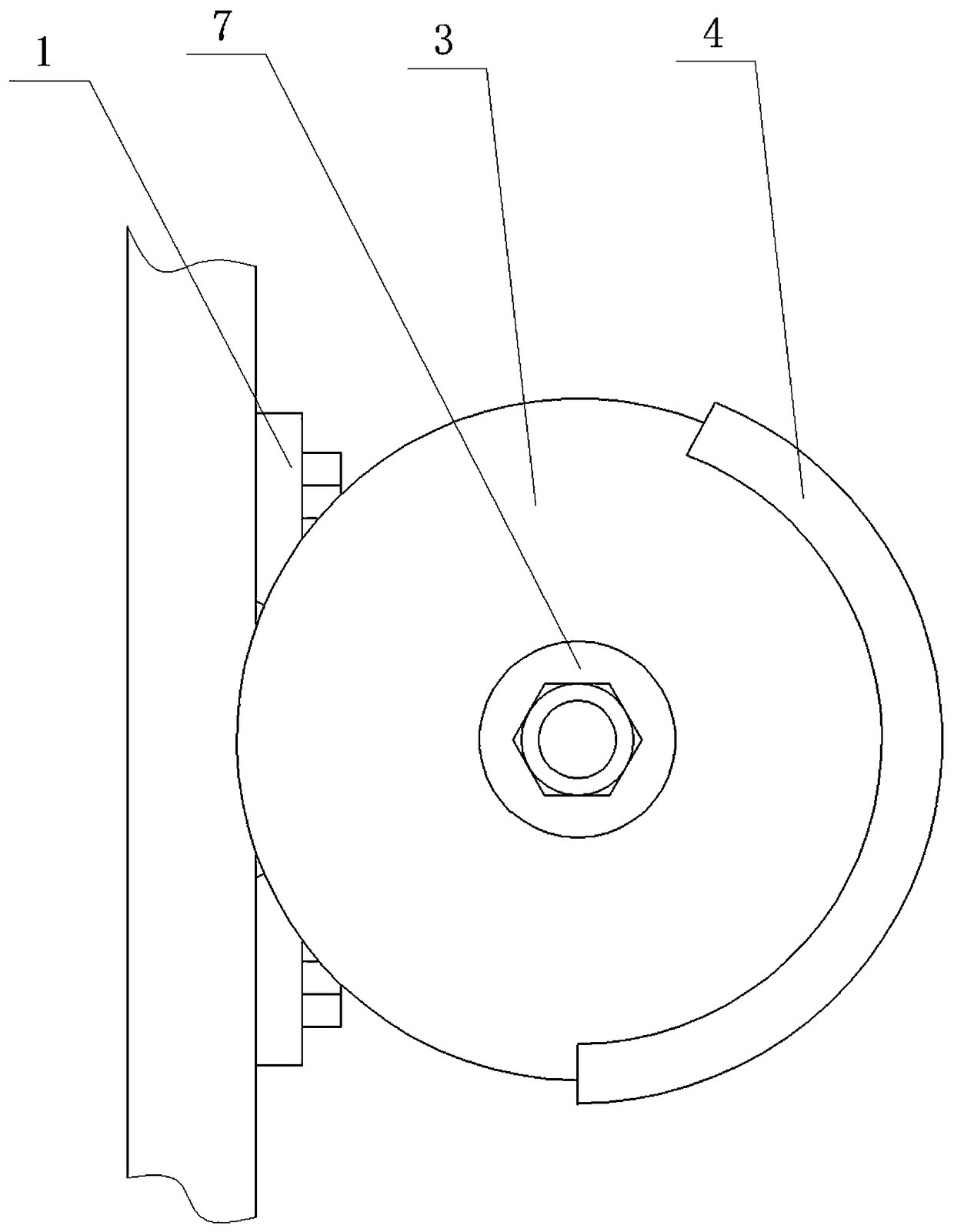

[0020] Such as Figure 1-3 As shown, a lathe grinding workpiece device includes a grinding wheel frame 1, a grinding wheel motor 2, a grinding wheel 3 and a grinding wheel cover 4. The grinding wheel frame 1 is fixed on the middle slide plate of the lathe by bolts, and of course it can also be fixed on the tool rest. Grinding wheel motor 2 is fixed on the grinding wheel frame 1, and one end of its main shaft is fixed with emery wheel 3 by nut, and grinding wheel motor 2 connects external power supply by electric wire and makes grinding wheel motor 2 work.

[0021] In this way, when it is necessary to process a circumferential groove with a high roughness (such as a roughness value of Ra 0.8) and a groove width of 15-20mm (of course, other groove widths are also possible, but it is best not to be greater than 40mm), the to-be-processed The workpiece is clamped in the way of "one clamp and one top". Adjust the middle slide plate to the appropriate position of the groove to be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com