Electrolyte and technique for preparing high-surface-quality barium strontium titanium ferroelectric film through micro-arc oxidation

A technology of barium strontium titanate and ferroelectric thin film, which is applied in the field of electrolyte for preparing high surface quality barium strontium titanate ferroelectric thin film by micro-arc oxidation, which can solve the problems of loose film surface, affecting film performance, and large roughness value , to achieve the effect of uniform diameter, good stability and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In-situ growth of barium strontium titanate ferroelectric thin film on commercially pure titanium TA2 specifically includes the following steps:

[0047] (1) Sample preparation: Cut the Ti plate into a substrate of 40*20*2mm, and grind the Ti substrate step by step with 180# to 1000# sandpaper until the surface is bright and smooth.

[0048] (2) Pre-treatment of the sample: Wash the polished Ti sheet in acetone and deionized water respectively, and dry it for later use.

[0049] (3) Electrolyte preparation: 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.02mol / LPVP as the solute, and deionized water as the solvent to prepare 1L electrolyte. The prepared electrolyte was stirred on a magnetic heating stirrer for 30 minutes, the heating temperature was set at 60° C., and the rotation speed was 1500 r / min.

[0050] (4) Ferroelectric thin film preparation: connect the titanium sheet pretreated in steps (1) and (2) to the anode, and place it in the electrolyte solution in step (...

Embodiment 2

[0053] In this embodiment, except for the composition of the electrolyte, other features are the same as those in Embodiment 1.

[0054] The electrolyte composition is as follows: with 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.03mol / LPVP as the solute, and deionized water as the solvent to prepare 1L of electrolyte.

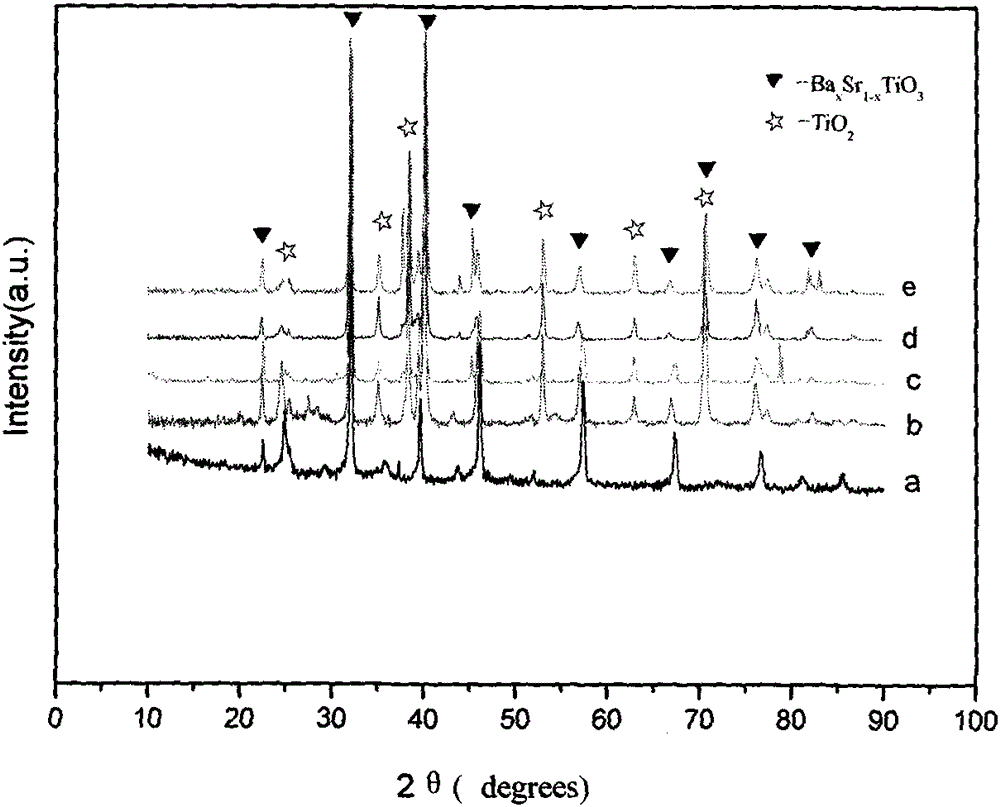

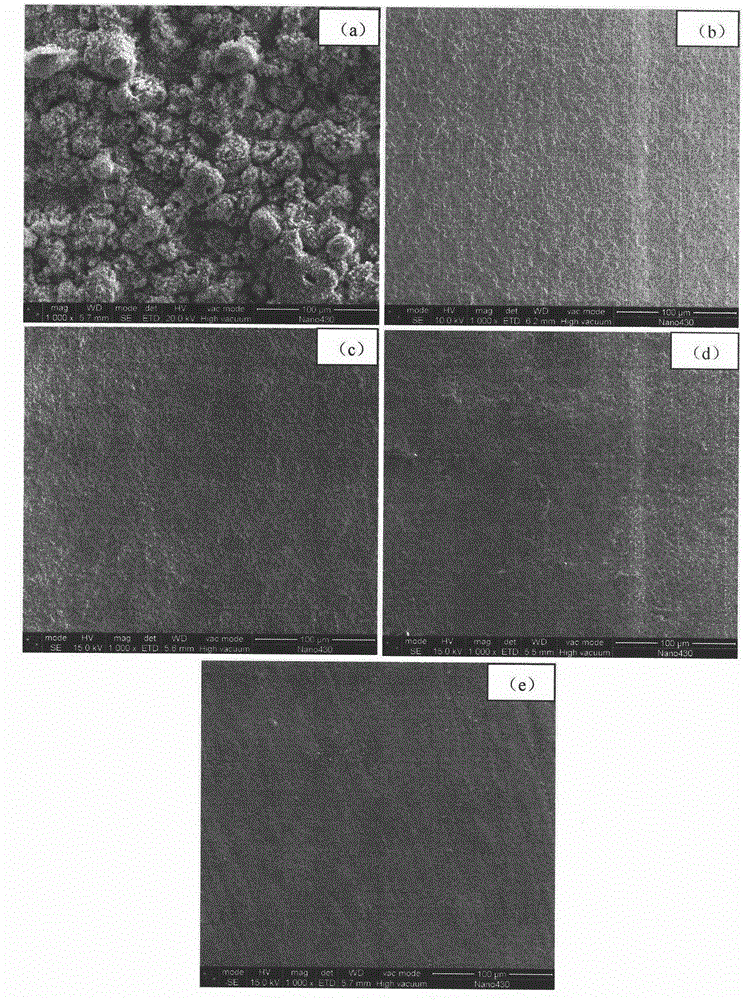

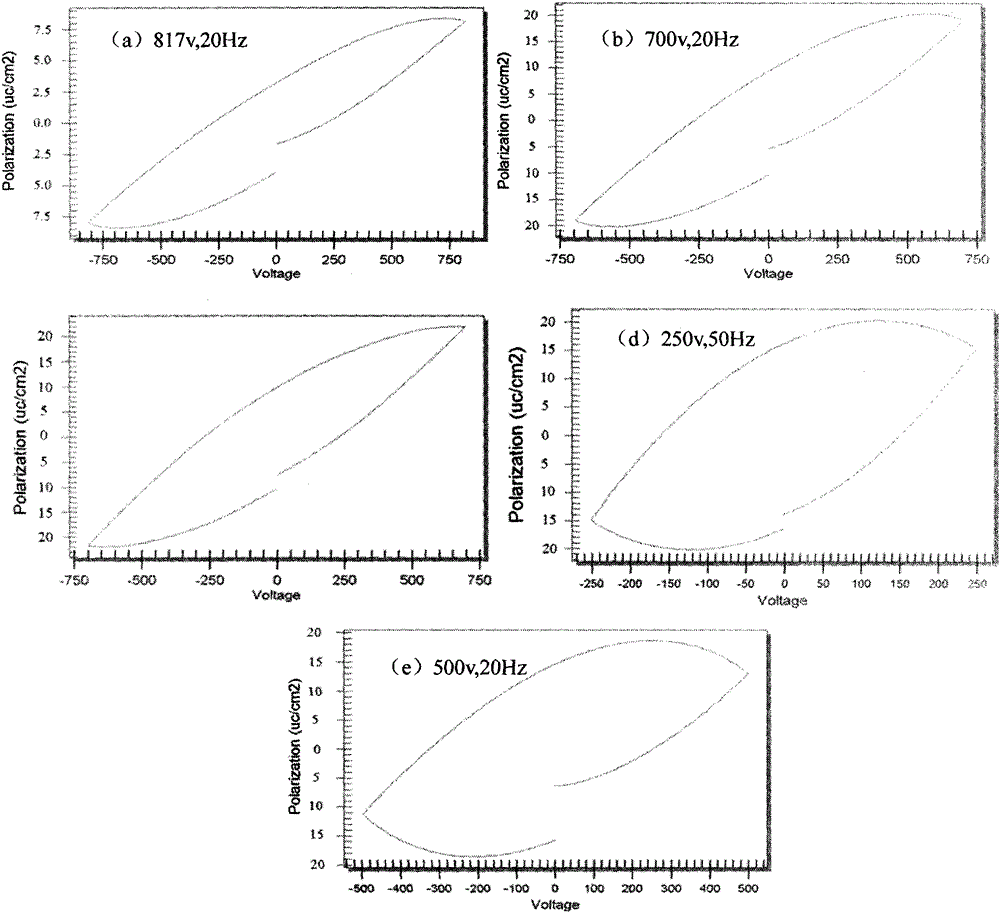

[0055] Gained thin film phase composition and surface appearance are similar to embodiment 1, and its SEM figure is as follows figure 2 (d) shown. The surface roughness of the film is about 0.377um, and the micro-arc oxidation hole diameter is about 300-800nm. The hysteresis loop of the thin film measured by the RADIANT Precision Premier II system is as follows: image 3 As shown in (d), under the conditions of 250V applied electric field and 50Hz frequency, the remnant polarization is about 18μC / cm 2 . The dielectric constant of the film is 280.2 and the dielectric loss is 0.048 under the condition of 1KHz measured by AGILENT4284APrecision LCRMETER system...

Embodiment 3

[0057] In this embodiment, except for the composition of the electrolyte, other features are the same as those in Embodiment 1.

[0058] The electrolyte composition is as follows: with 0.5mol / LBa(OH) 2 , 0.5mol / LSr(OH) 2 and 0.04mol / LPVP as the solute, and deionized water as the solvent to prepare 1L of electrolyte.

[0059] Gained thin film phase composition and surface appearance are similar to embodiment 1, and its SEM figure is as follows figure 2 (e) shown. The surface roughness of the film is about 0.303um, and the micro-arc oxidation hole diameter is about 500-700nm. The hysteresis loop of the thin film measured by the RADIANT Precision Premier II system is as follows: image 3 As shown in (e), under the condition of 500V applied electric field and 20Hz frequency, the remnant polarization is about 15μC / cm 2 . The dielectric constant of the film is 530.8 and the dielectric loss is 0.195 under the condition of 1KHz measured by AGILENT4284APrecisionLCRMETER system (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com