Drill rod inserting system

A technology for inserting brazing and beams, applied in the field of aerated concrete block production, can solve the problems of low pillar efficiency and easy damage to the green body, and achieve the effects of improving production efficiency, reducing labor intensity and shortening installation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

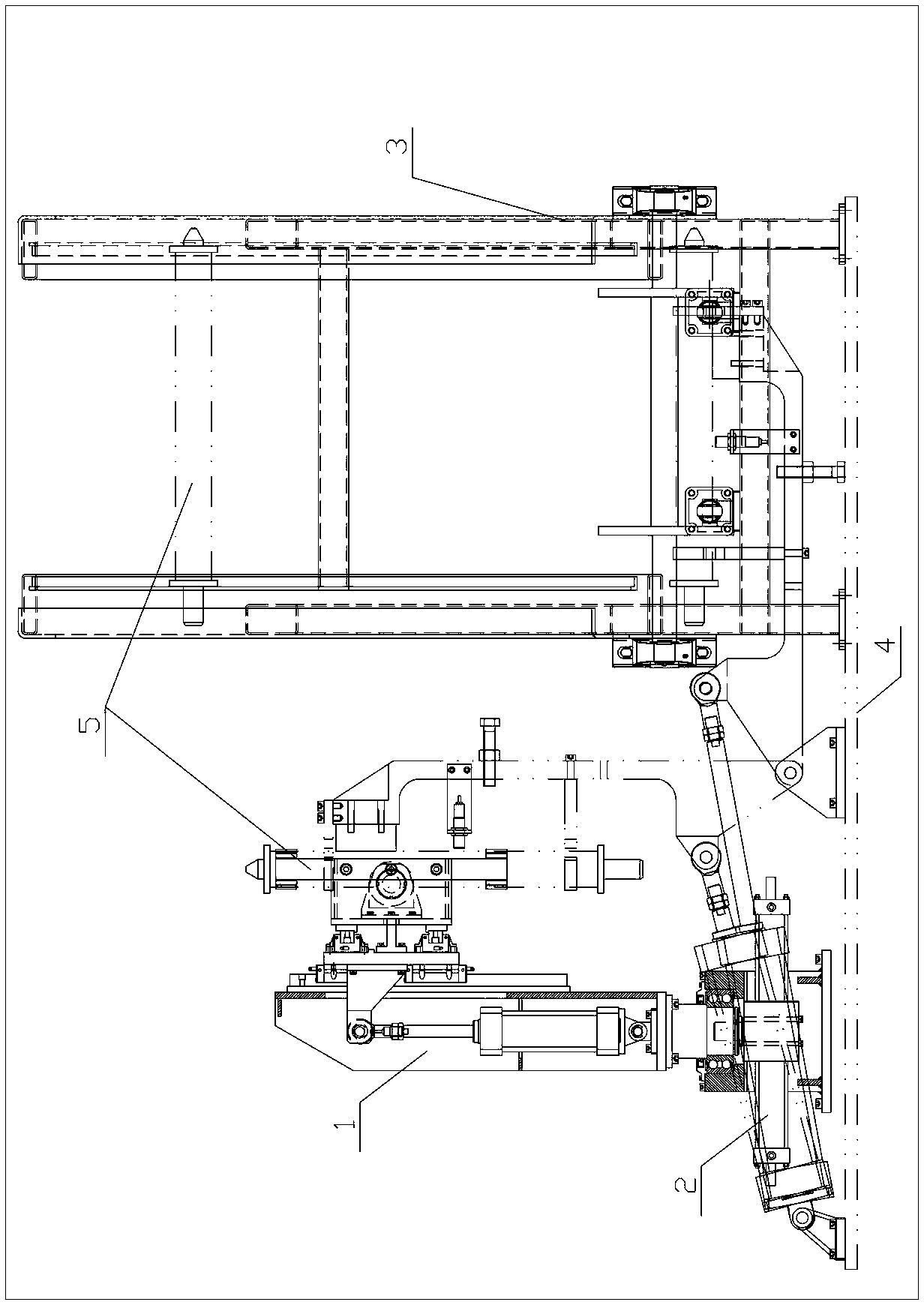

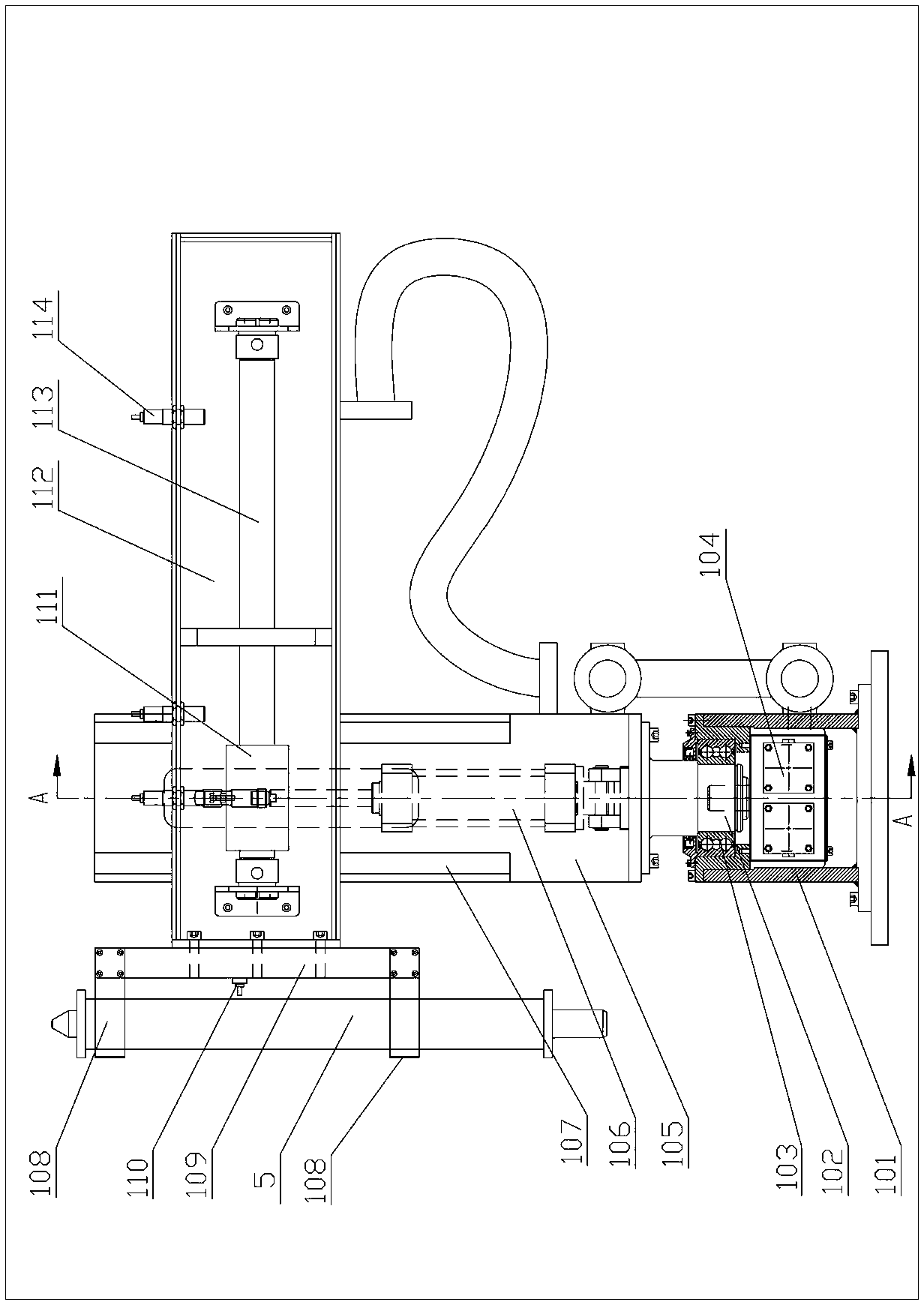

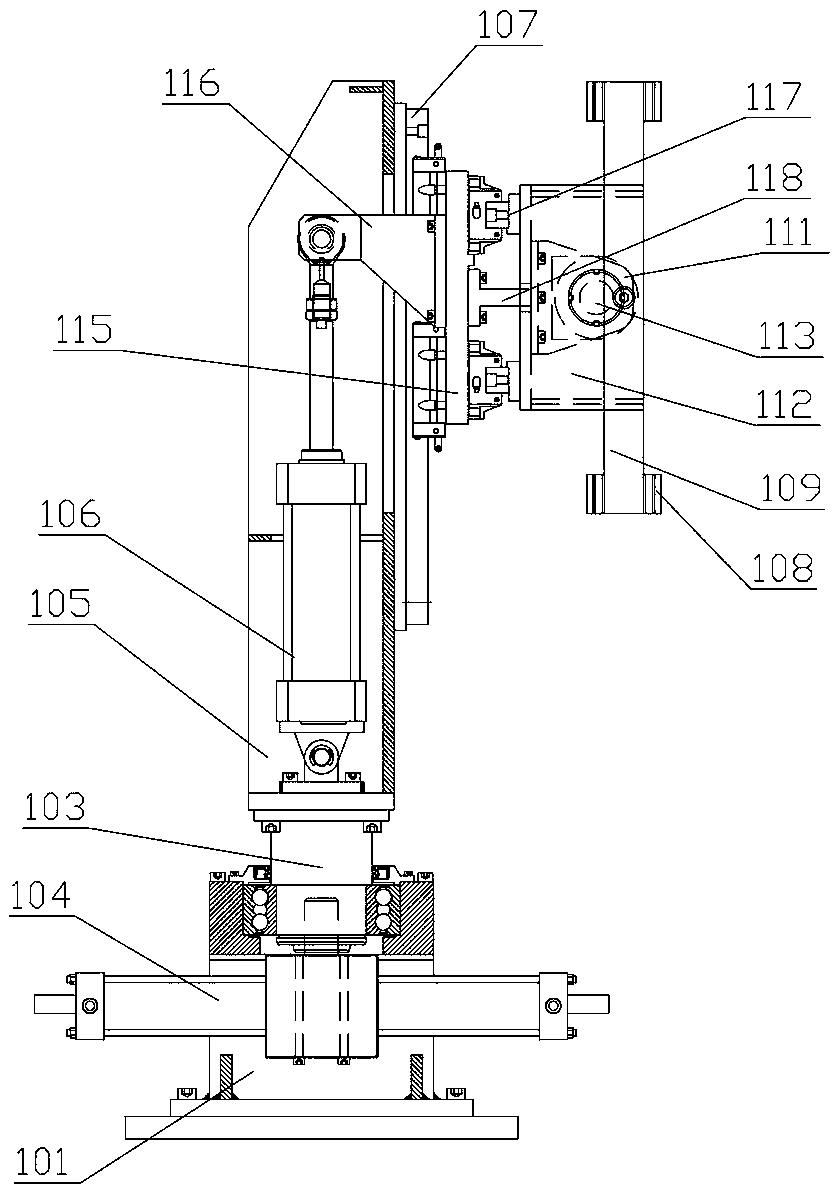

[0024] see figure 1 , the present embodiment comprises a base plate 4, on which a brazing device 1, a rotating device 2, and a conveying device 3 are mounted, see Figure 2-4 , the inserting device 1 includes a fixed base 101, the top of the fixed base 101 is equipped with a rotating shaft 102 through a slewing bearing 103, a rotary drive mechanism 104 connected with the rotating shaft 102 is housed in the fixed base 101, and a vertical beam 105 is fixedly installed on the rotating shaft 102, and the vertical beam The inside of 105 is equipped with a driving mechanism 106 for inserting brazing, and the middle of the vertical beam 105 is provided with a vertically elongated through hole. Slide seat 115 is housed on rail A107, and slide seat 115 is equipped with connection seat 116 on one side facing vertical beam 105, and connection seat 116 passes through elongated through hole and is hinged with inserting brazing drive mechanism 106, and slide seat 115 other side is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com