Pipeline steel X70 steel plate in low compression ratio, and production method thereof

A technology with low compression ratio and production method, which is applied in the field of high-strength and high-toughness pipeline steel X70 steel plate to produce low compression ratio. It can solve the problems of low impact toughness and failure to meet engineering technical requirements, etc., to improve drop hammer performance, The effect of increasing the uniform elongation of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The chemical composition (wt%) of the low compression ratio pipeline steel X70 hot-rolled flat plate in this example is shown in Table 1.

[0023] Table 1 Chemical composition (wt%) of low compression ratio pipeline steel X70 steel plate

[0024] element

C

Si

mn

P

S

Nb

Ti

Alt

content

0.07

0.20

1.70

0.009

0.003

0.050

0.012

0.035

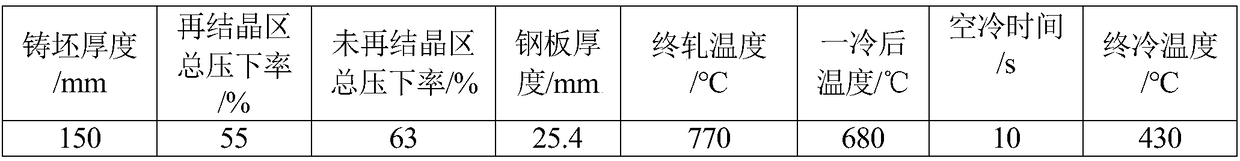

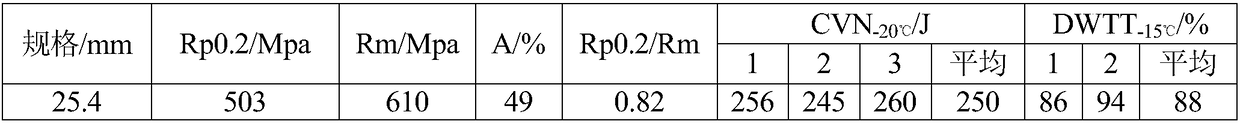

[0025] The specific parameters of the rolling process and the laminar flow staged cooling process in the production process of the low compression ratio pipeline steel X70 steel plate in this embodiment are shown in Table 2.

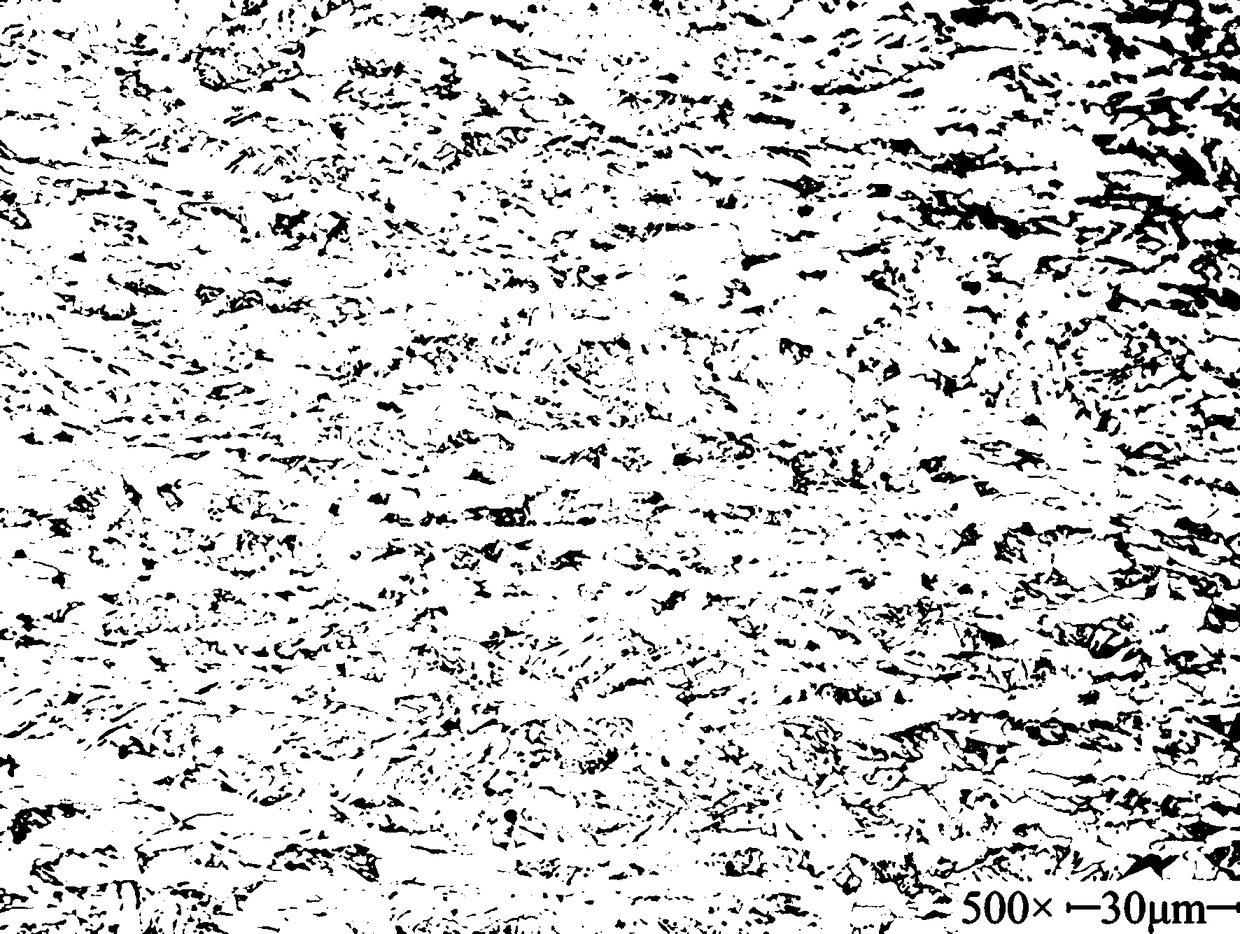

[0026] The production process of the low compression ratio pipeline steel X70 steel plate in this embodiment: the reheating temperature is 1250° C., and the furnace time is 3 hours. Two-stage controlled rolling is adopted, rough rolling is rolling in the recrystallization zone for 4 passes, the starting rolling temperature is 1100°C, and the final ...

Embodiment 2

[0034] The chemical composition (wt%) of the low compression ratio pipeline steel X70 hot-rolled flat plate in this embodiment is shown in Table 4.

[0035] Table 4 Chemical composition (wt%) of low compression ratio pipeline steel X70 steel plate

[0036] element

C

Si

mn

Cr

P

S

Nb

Ti

Alt

content

0.05

0.22

1.60

0.20

0.010

0.002

0.052

0.014

0.038

[0037] The production process of the low compression ratio pipeline steel X70 steel plate in this embodiment: the reheating temperature is 1250° C., and the furnace time is 3 hours. Two-stage controlled rolling is adopted, rough rolling is rolling in the recrystallization zone for 4 passes, the starting rolling temperature is 1100°C, and the final rolling temperature is 1085°C; the thickness of the intermediate billet is 69mm, and the finishing rolling is rolling in the non-recrystallization zone for 7 passes. The rolling start temperature is 870°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com