Preparation method and application of x80m pipeline steel resistant to low temperature and large strain

A pipeline steel, large strain technology, applied in the field of X80M pipeline steel and its preparation, can solve the problems of small temperature drop range, inapplicability, specification restrictions, etc., to increase the position of phase deformation nuclei, increase the uniformity of the structure, and refine the grain size. effect of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The present embodiment is that the concrete composition of 33mmX80M is as shown in table 1.

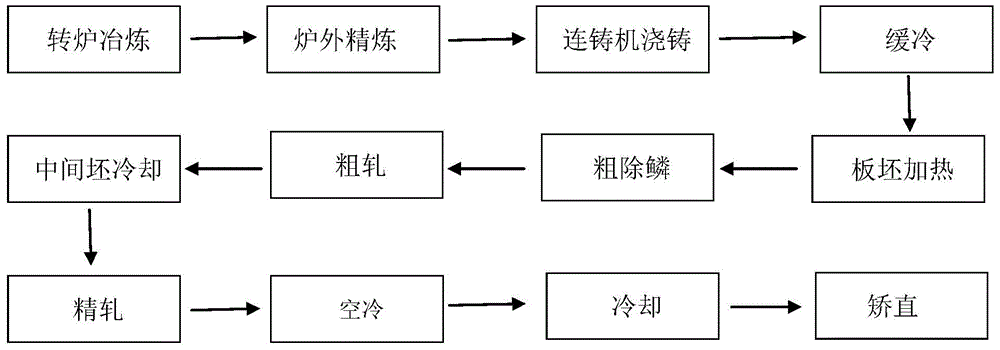

[0067] The production and preparation method of a kind of low temperature large strain thick specification X80 pipeline steel plate of the present embodiment is as follows (according to figure 1 The process flow shown is prepared):

[0068] (1) Smelting and continuous casting process: the clean steel smelting method is adopted, and on the basis of ultra-low P and S, the total amount of five harmful elements is controlled to ensure the purity and uniformity of steel quality. During the slab continuous casting process, the dynamic soft reduction technology is adopted, the center segregation of the slab reaches C class 0.5, and the thickness of the slab is 300mm.

[0069] Table 1 33mm X80M chemical composition (%)

[0070]

[0071] (2) Slab heating: In the slab heating step, the slab heating temperature is 1140°C.

[0072] (3) Rough descaling: control the slab temperature in...

Embodiment 2

[0081] The present embodiment is that the concrete chemical composition of 27mm X80M is as shown in table 2.

[0082] The production and preparation method of a low-temperature large-strain thick specification X80 pipeline steel plate in this embodiment is as follows:

[0083] (1) Smelting and continuous casting: the clean steel smelting method is adopted, and on the basis of ultra-low P and S, the total amount of five harmful elements is controlled to ensure the purity and uniformity of steel. The main chemical composition of the steel is shown in Table 2. During the slab continuous casting process, the dynamic soft reduction technology is adopted, and the quality of the slab reaches Class C 0.5, and the thickness of the slab is 300mm.

[0084] Table 2 27mm X80M chemical composition

[0085] C Si mn P S Ti Nb Zr Cr Ni Cu Al H 0 N 0.05 0.26 1.70 0.008 0.002 0.017 0.065 0.019 0.22 0.10 0.12 0.029 0.0003 0.0011 0.0028

[0086]...

Embodiment 3

[0096] The present embodiment is that the concrete chemical composition of 26.4mm X80 is as shown in table 3.

[0097] The production and preparation method of a low-temperature large-strain thick specification X80 pipeline steel plate in this embodiment is as follows:

[0098] (1) Smelting and continuous casting: the clean steel smelting method is adopted, and on the basis of ultra-low P and S, the total amount of five harmful elements is controlled to ensure the purity and uniformity of steel. The main chemical composition of the steel is shown in Table 3: During the slab continuous casting process, the dynamic soft reduction technology is adopted, the quality of the cast slab reaches C class 0.5, and the thickness of the cast slab is 300mm.

[0099] Table 3 26.4mm X80 chemical composition

[0100] C Si mn P S Ti Nb Zr Cr Ni Cu Al H 0 N 0.06 0.24 1.73 0.008 0.002 0.016 0.065 0.021 0.22 0.10 0.11 0.032 0.0001 0.0013 0.0024 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com