Vertical circulating garage carrying hanging bracket with 360-degree unobstructed rotating carrying plate

A technology of vertical circulation and car-carrying plate, applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve the problems of time-consuming, long waiting time in queue, etc., to ensure flexibility, save waiting time, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

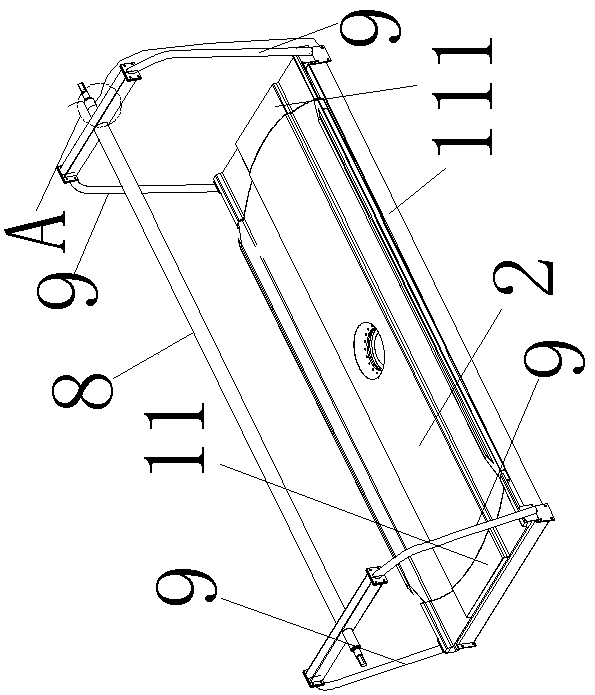

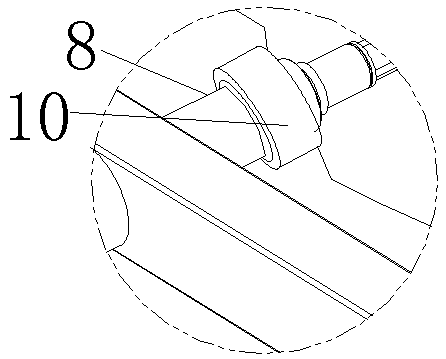

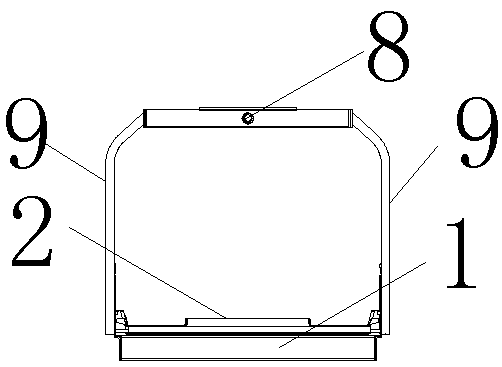

[0058] Example 1. Such as Figure 1-Figure 13 As shown, the vertical circulation garage vehicle-carrying hanger with 360-degree unobstructed rotating vehicle-carrying plate is characterized in that: the vehicle-carrying hanger includes a vehicle-carrying platform chassis 1, a rotatable car-carrying plate 2, a slewing bearing 3, Ring-shaped rolling support device mounting seat 4, rolling support device 5, rotatable vehicle-carrying plate electric drive device 6, and the center of the top surface of the vehicle-carrying platform chassis 1 is equipped with a slewing bearing 3 and a circular rolling support device mounting seat 4. The centroid of the bottom surface of the rotatable vehicle loading plate 2 is located directly above the centroid of the top surface of the vehicle loading platform chassis 1. The centroid of the rotatable vehicle loading plate 2 is provided with a mounting hole 7, and the ring-shaped rolling support device A number of rolling support devices 5 are ins...

Embodiment 2

[0063] Example 2. Such as Figure 14-29 As shown, the difference between this embodiment and Embodiment 1 is that: the rotatable vehicle-carrying plate 2 is provided with a number of wheel stop devices 19, and the wheel stop devices 19 include a frame body 12 with a rectangular cross section; the frame body 12 Be fixed in the upward square hole 13 of the opening on the top surface of the rotatable car-carrying plate 2 of the three-dimensional garage.

[0064] The right side of the left side 121 of the frame body 12 and the bottom end of the left side of the right side 122 are respectively provided with longitudinal rails 20 , and the front end of the frame body 12 is hinged with a first square panel 14 .

[0065] The rear end of the first square panel 14 is hinged with a second square panel 15; the left and right sides of the rear end of the second square panel 15 can slide on the longitudinal rail 20 respectively; 16. A horizontal plate 17 is connected to the front ends of ...

Embodiment 3

[0073] Example 3. Such as Figure 24 As shown, the difference between the present embodiment and Embodiment 2 is: a rotatable front shaft 31 is installed between the right side of the left side of the frame body 12 and the front end of the left side of the right side 122, and the front shaft 31 The first square panel 14 is connected on the rear side; the two ends of the front rotating shaft 31 are respectively connected with the right side of the left side of the frame body 12 and the left side of the right side 122 through a front bearing 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com