Fatigue test tool for flange face fastener

A fatigue test and fastener technology, which is applied in the field of fatigue test tooling for flange surface fasteners, can solve problems such as tooling friction and inaccurate center positioning of test samples, and achieve convenient center positioning, good positioning performance, and guaranteed measurement The effect of the result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

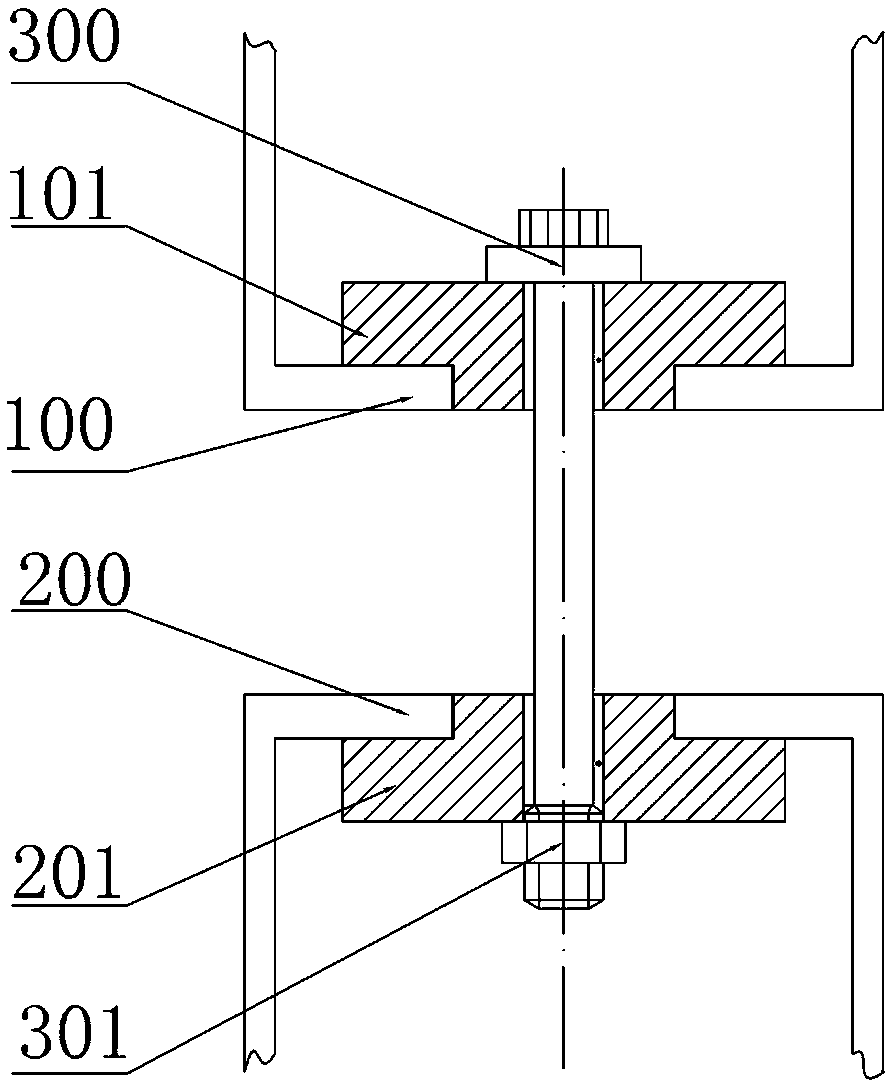

[0028] Such as Figure 4 to Figure 7 As shown, an embodiment of a fatigue test tool for flange surface fasteners, the fatigue test tool in this embodiment and the fatigue test tool commonly used in the prior art also include upper and lower clamps and correspondingly arranged on the upper and lower clamps The upper gasket and the lower gasket on the upper gasket are provided with a vertical center hole for the rod gap of the flange surface fastener to be tested to pass through and a method for connecting the flange surface fastener to be tested. The blue support portion supports the horizontal support surface of the press fit.

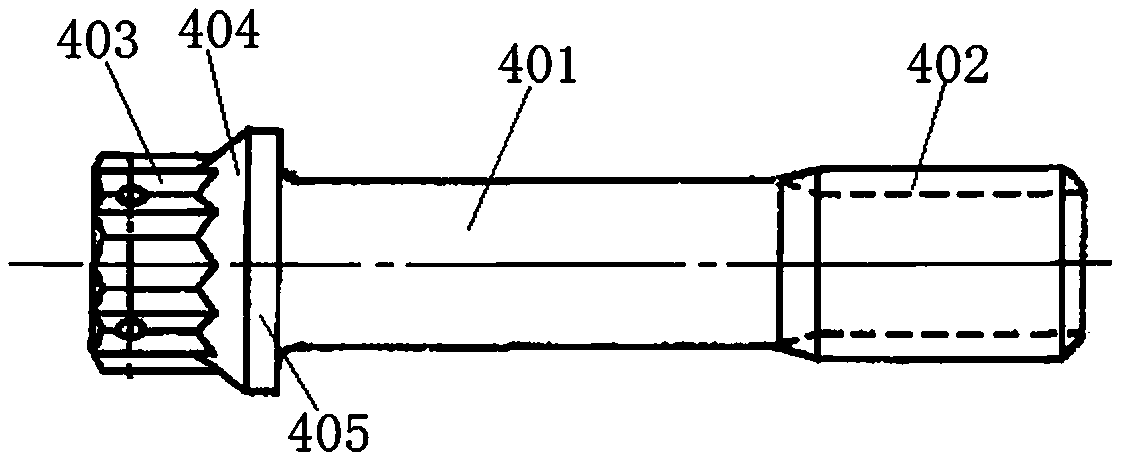

[0029] What is different from the prior art is that the test fixture in this embodiment also includes a clamping and positioning flange surface fastener 50 to be tested on the horizontal support surface of the upper gasket so that it is aligned with the vertical center of the upper gasket. A central positioning device 40 arranged coaxially with the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com