Battery box

A battery box and storage battery technology, applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of water ingress, humidity, battery impact, and impact on battery work and life, and achieve enhanced stability, improved heat dissipation, The effect of improving insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

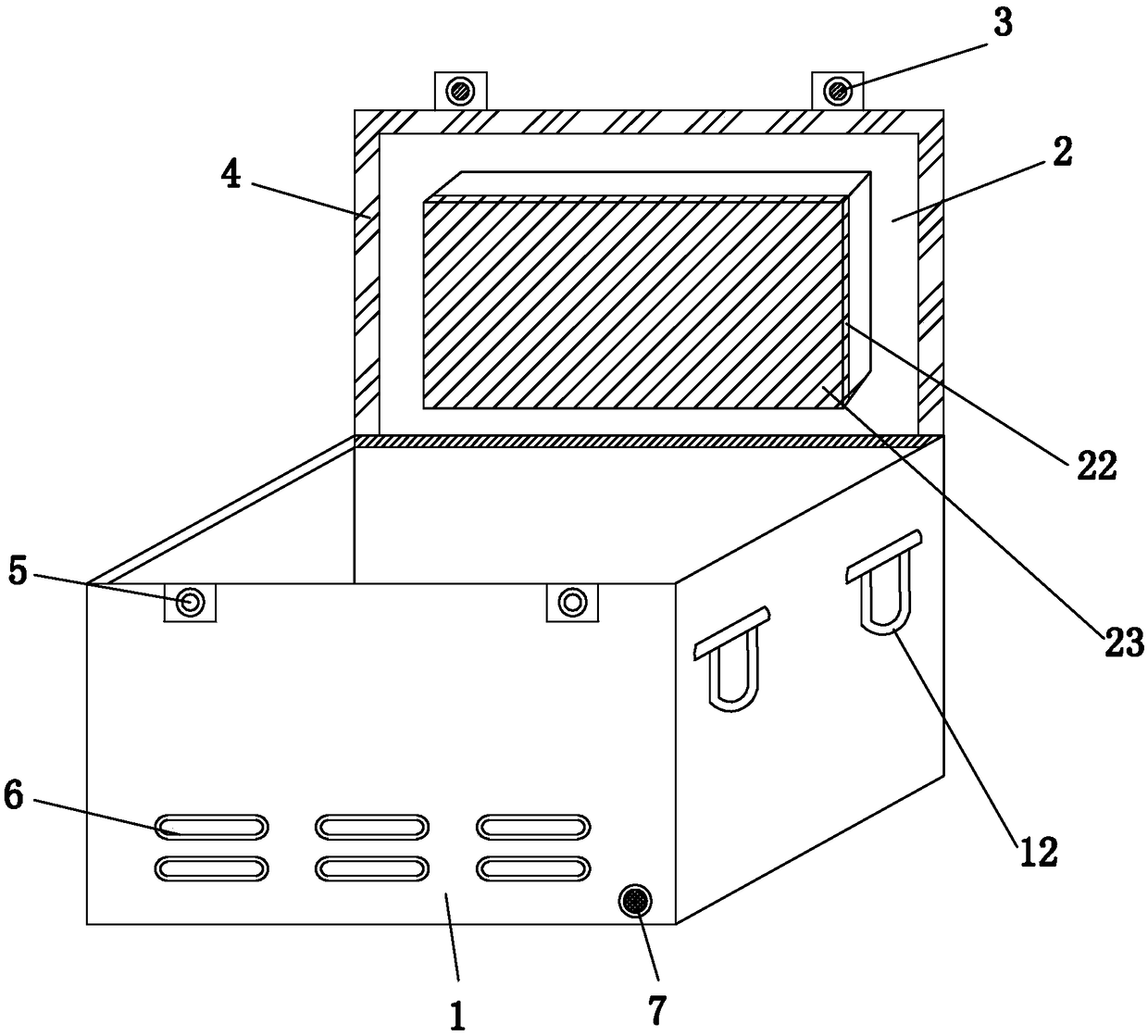

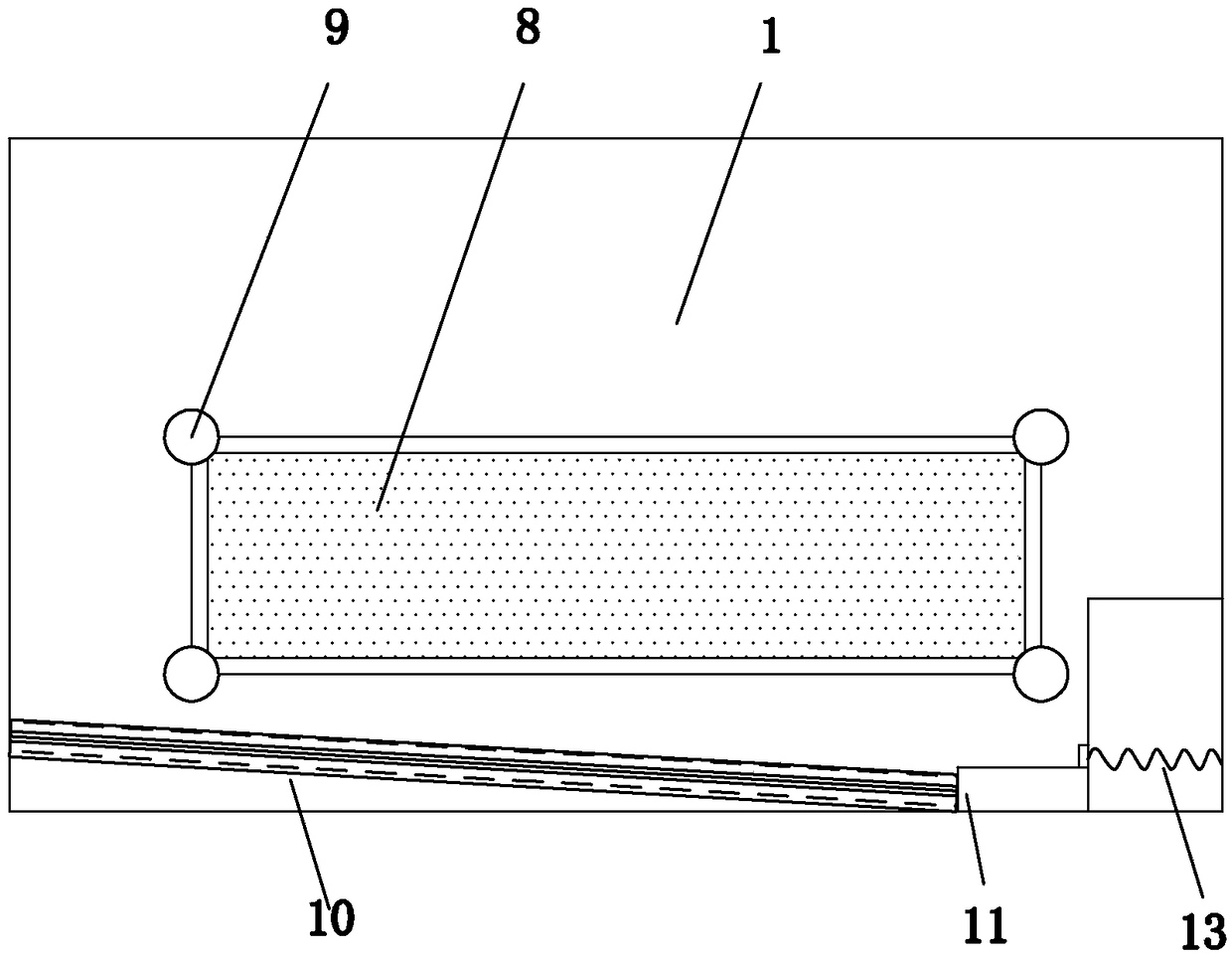

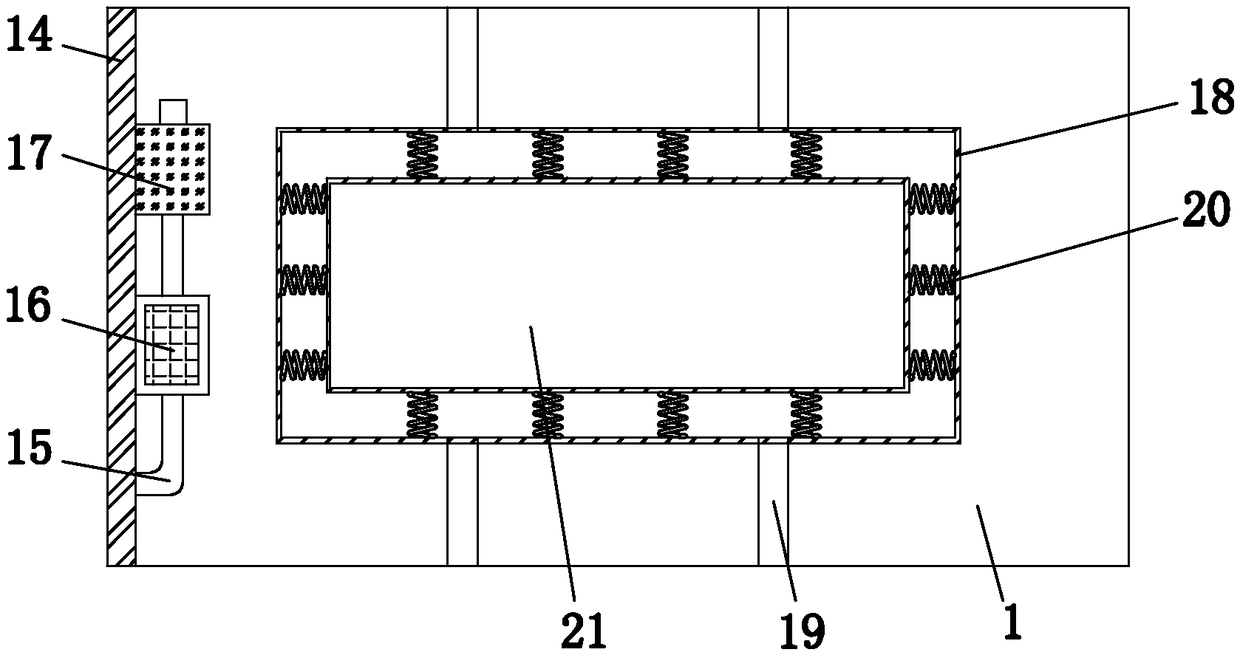

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 shown;

[0026] A battery box according to the present invention, comprising a battery box body 1, the surface of the battery box body 1 is provided with an air guide groove 6, and a dust-proof net is installed on the inner wall of the battery box body 1 opposite to the air guide groove 6 8;

[0027] Below the inner bottom dust-proof net 8 of the battery box body 1, there is a drainage groove 10 arranged obliquely. One end of the drainage groove 10 is connected with a water inlet pipe 11. In the water storage chamber 13, a water outlet 7 is opened under the front of the battery box body 1;

[0028] An insulating frame plate 18 is arranged in the middle of the battery box body 1, an insulating support rod 19 is installed at the interval between both sides of the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com