Device for filtering and turning impurities in cotton and linen cloth material washing water

A technology for impurity filtration and washing water, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of sewer pipe blockage and other problems, and achieve the effect of high efficiency in the filtration and dumping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

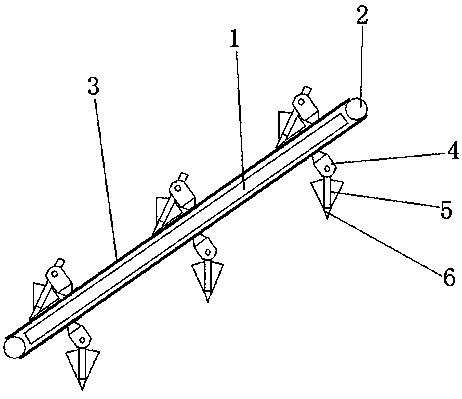

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] A device for filtering and overturning impurities in washing water of cotton and linen fabrics, comprising a slant plate 1, a rotating roller 2 is provided at both ends of the sloping plate 1, the inclination angle of the sloping plate 1 can be adjusted according to needs, surrounding two rotating rollers 2 and The inclined plate 1 is provided with a belt 3, and the surface of the inclined plate 1 has rollers to facilitate the movement of the belt 3. The belt 3 has a certain width, and the end of the rotating roller 2 has a motor, which drives the rotating roller 2 to rotate to realize the rotation of the belt;

[0016] The belt 3 is provided with a filtering mechanism, and the filtering mechanism includes side stoppers 4 arranged on both sides of the belt 3. The side stoppers 4 and the belt 3 are flexibly connected, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com