Special sulfur conveying and connecting device

A connecting device, sulfur technology, applied in the direction of grain processing, etc., can solve the problems of affecting the collection work, high overall cost, and inability to ensure the uniformity of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

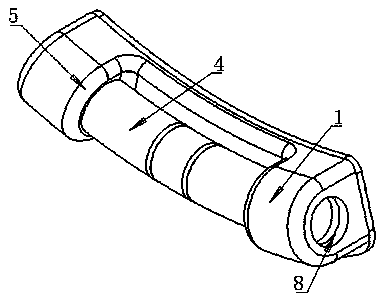

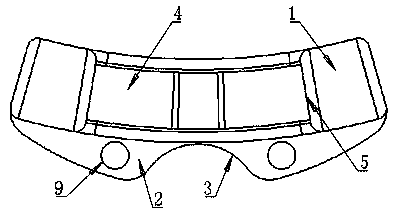

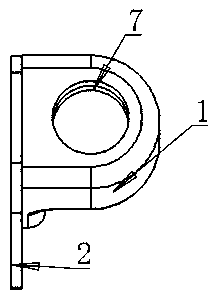

[0018] Such as Figure 1 to Figure 7 As shown in the figure, a special sulfur transport connection device is installed at the output port of the crushing assembly during assembly, through which the crushed sulfur can be filtered and output to ensure that the crushing degree of the output sulfur can meet the expected requirements , this part also sets the output structure into a circular arc shape to make the output more stable, and sets a freely movable elliptical filter connection sphere inside the output structure, so that the sulfur can pass through the inside of the device for output. The speed is more stable, which makes the safety and stability of the final sulfur collection process better. This device can facilitate production personnel to observe during use, ensuring that the output sulfur can be observed more intuitively, making the production process more convenient. Stronger. It includes an arc-shaped main body conveying structure 1, the center of the arc of which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com