A high-efficiency wet ball milling equipment

A technology of wet ball milling and ball milling, which is applied in the direction of grain processing, etc., and can solve the problems of uneven crushing, uneven rollers, and the inability to realize automatic forward feeding of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

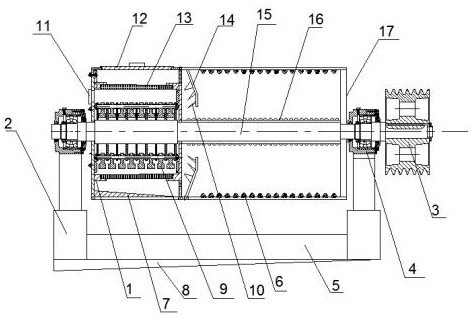

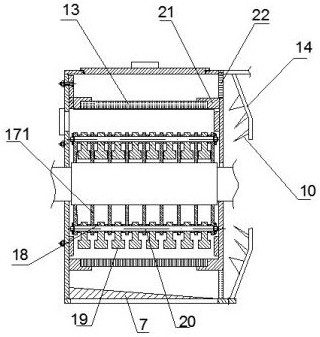

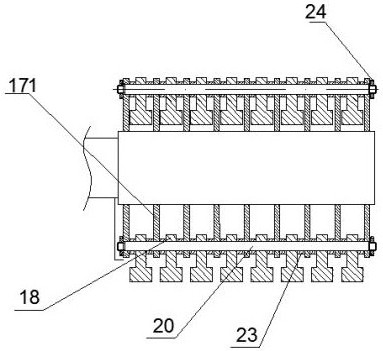

[0022] see Figure 1~4 , in an embodiment of the present invention, a high-efficiency wet ball milling equipment includes a support mechanism, a ball milling drum assembly and a driver, the ball milling drum assembly is supported on the supporting mechanism, and the ball milling drum assembly is driven by the driver Rotate and rotate; it is characterized in that the ball milling drum assembly includes a hammering drum 12 and a ball milling drum 17 coaxially arranged in one piece, the hammering drum 12 is provided with a hammer for hammering and pulverizing the slurry or powder to be ground impact mechanism, and a filter communication mechanism and a guide mechanism are also provided between the hammer drum 12 and the ball mill drum 17, and the filter communication mechanism can hammer the slurry or powder to be ground after the hammer drum 12 Filter and flow to the ball mill cylinder 17, the guide mechanism can make the slurry or powder to be refined flow towards the ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com