Flushing method for powder conveying pipeline

A technology for conveying pipelines and powder materials, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of blocked pipelines, easy to adhere to the pipe wall, and pipeline blockages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

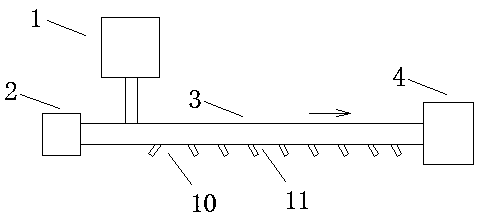

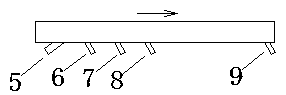

[0009] At the starting end of the transmission pipeline close to the discharge port of the lime silo, several sections of flushing pipelines are welded. On-off valves are installed on the flushing pipelines and the other end of the flushing pipelines is connected to the flushing gas source. The on-off valves can be solenoid valves or electric valves. figure 1 The arrow in the figure indicates the transportation direction of the powder transported by the transmission pipeline. The opening and closing of the flushing pipeline is controlled by the on-off valve. The flushing pipeline is divided into a main flushing pipeline and an auxiliary flushing pipeline. The installation sequence of the flushing pipeline is as follows: The main pipeline and the transmission pipeline form an angle, which is called the X angle. Starting from the main pipeline for flushing, along the transmission direction of the transmission pipeline, an auxiliary pipeline for flushing is set at a certain distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com