A Cleaning Method for Semi-closed Complex Inner Cavity Castings

A semi-closed cleaning method technology, applied in the field of casting, can solve the problems of difficult tool cleaning operation, time-consuming and labor-consuming, limited cleaning angle, etc., to achieve the effect of ensuring surface quality, improving cleaning efficiency, and large reflection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

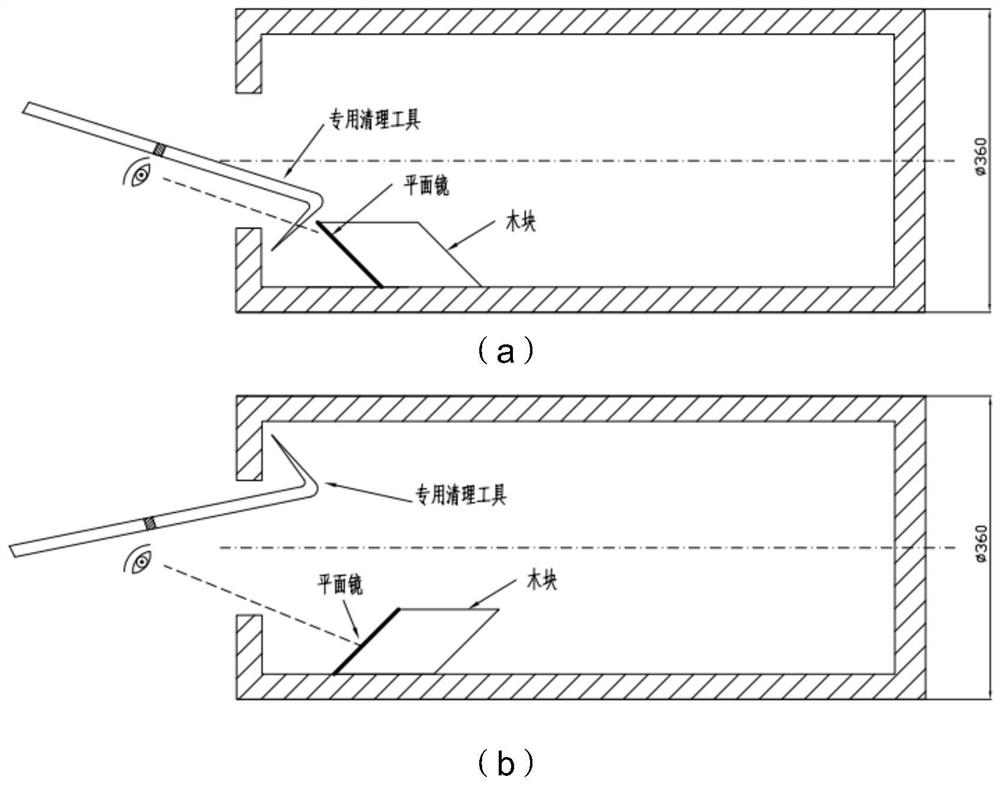

[0020] Such as figure 1 as shown, figure 1 In (a), when cleaning the lower surface of the inner cavity of the casting, turn the mirror face of the speculum downward, and then the dead angle of the lower inner cavity can be clearly observed; figure 1 In (b), when cleaning the upper surface of the inner cavity of the casting, there is no need to turn the casting, and the mirror surface of the viewing mirror is turned upward, so that the dead angle of the upper inner cavity can be clearly observed.

[0021] The peep mirror of the present invention is manufactured by adopting an angled diamond-shaped wooden block to fix the plane mirror. The size of the plane mirror is: 150mm×70mm, the size of the diamond-shaped wooden block is: 150mm×70mm×70mm, and the angle of the rhombus is 45°, which can be changed according to the shape of the casting.

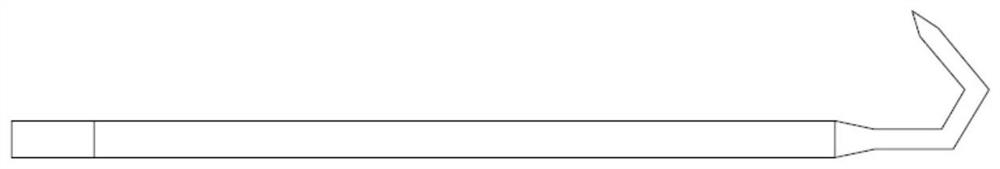

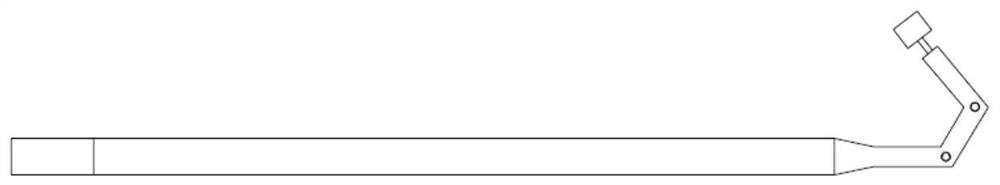

[0022] When performing cleaning operations, the pneumatic wind shovel (such as figure 2 shown) to remove the large volume of sand-packed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com