Visual inspection system

A technology of visual inspection and mounting frame, which is applied in the field of visual inspection system, can solve the problems of low efficiency of lens calibration and achieve the effect of improving versatility and calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

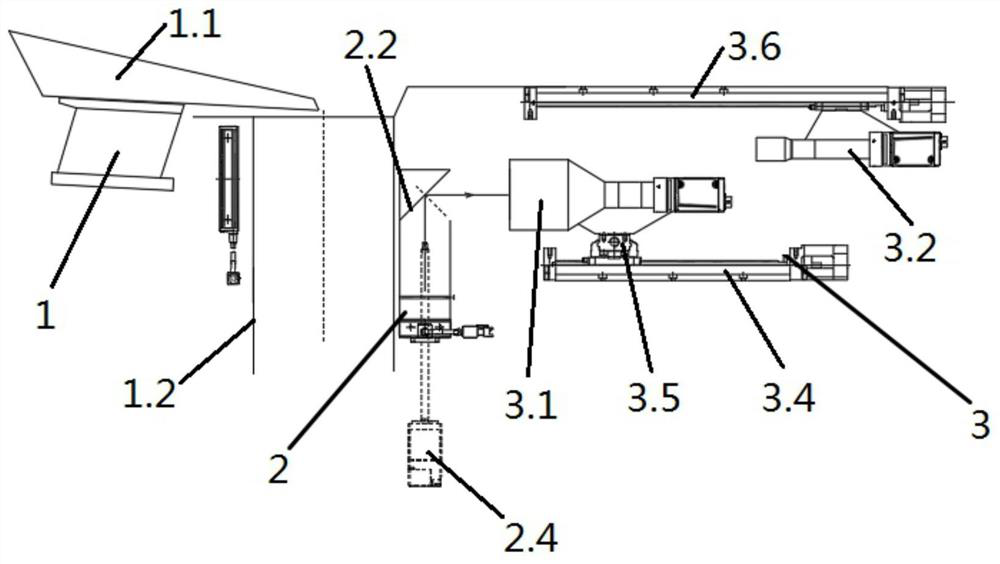

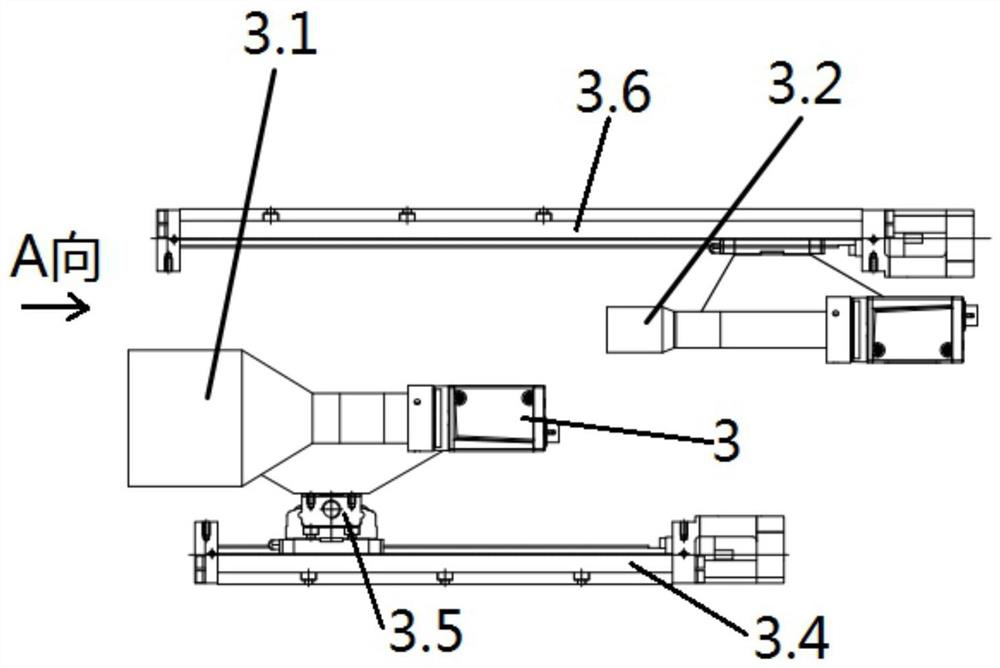

[0037] see Figure 1 to Figure 6 , a visual inspection system, this embodiment is applied to lens calibration and aggregate inspection of a visual inspection system.

[0038] A visual detection system comprising a blanking unit 1, a calibration unit 2, an image acquisition unit 3 and a control unit; the blanking unit 1, the calibration unit 2 and the image acquisition unit 3 are all connected to the control unit by signals;

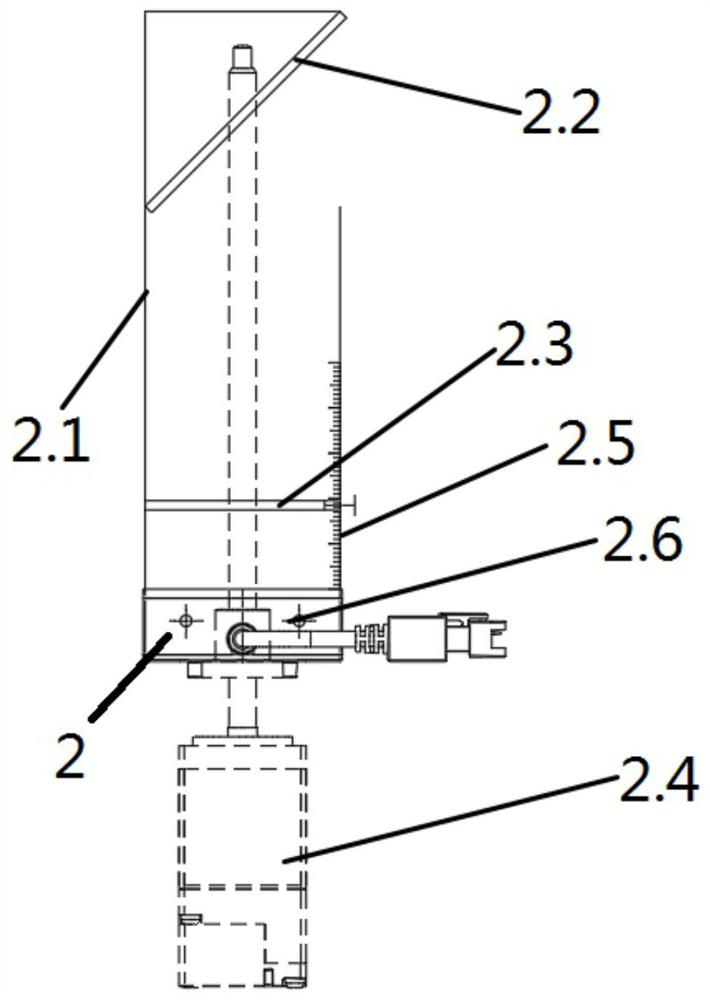

[0039] see Figure 1 to Figure 2 , the calibration unit 2 includes a mounting frame 2.1, a mirror 2.2, and a calibration plate 2.3; the calibration plate 2.3 is horizontally arranged on the mounting frame 2.1, and a pattern array with a fixed spacing is provided on the calibration plate 2.3 for visual Calibration of the detection system: the reflective mirror 2.2 is arranged on the mounting frame 2.1, and the reflective mirror 2.2 is located above the calibration plate 2.3, and the reflective mirror 2.2 is at an angle of 45° with the horizontal plane; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com