A solder handle fixing steel ring

A technology for fixing steel rings and handles, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor adjustability of fixed steel rings, decreased installation tightness, and unchanged maintenance, and achieves a significant fixing effect, The effect of stable installation and strong magnetic attraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

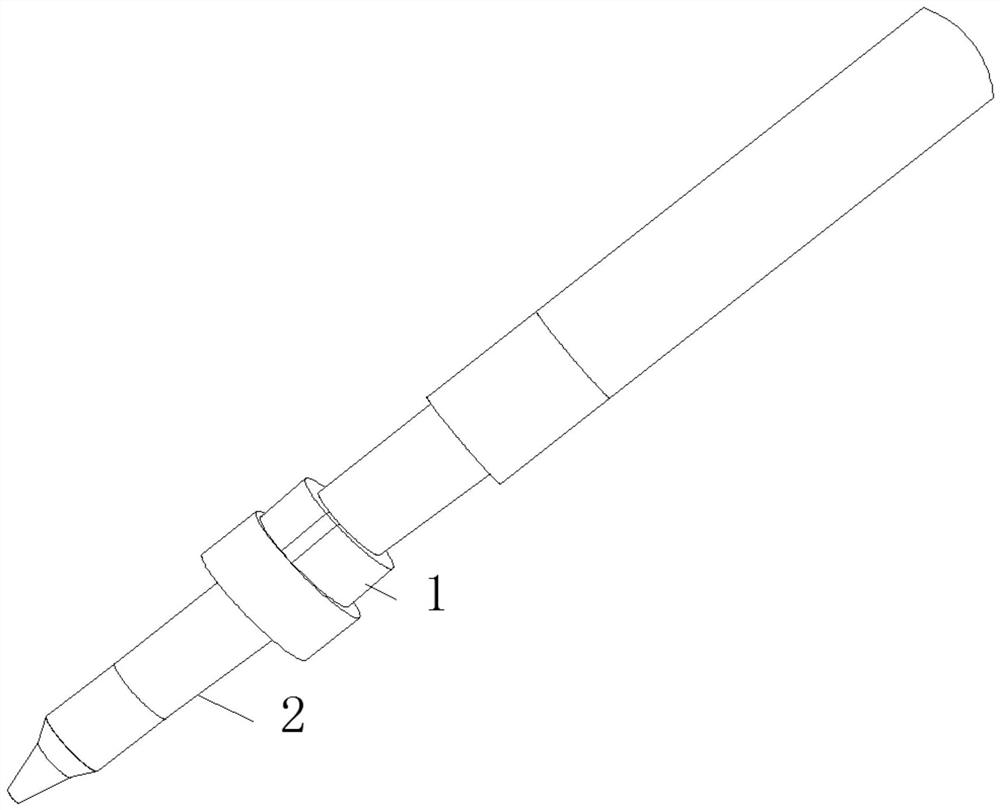

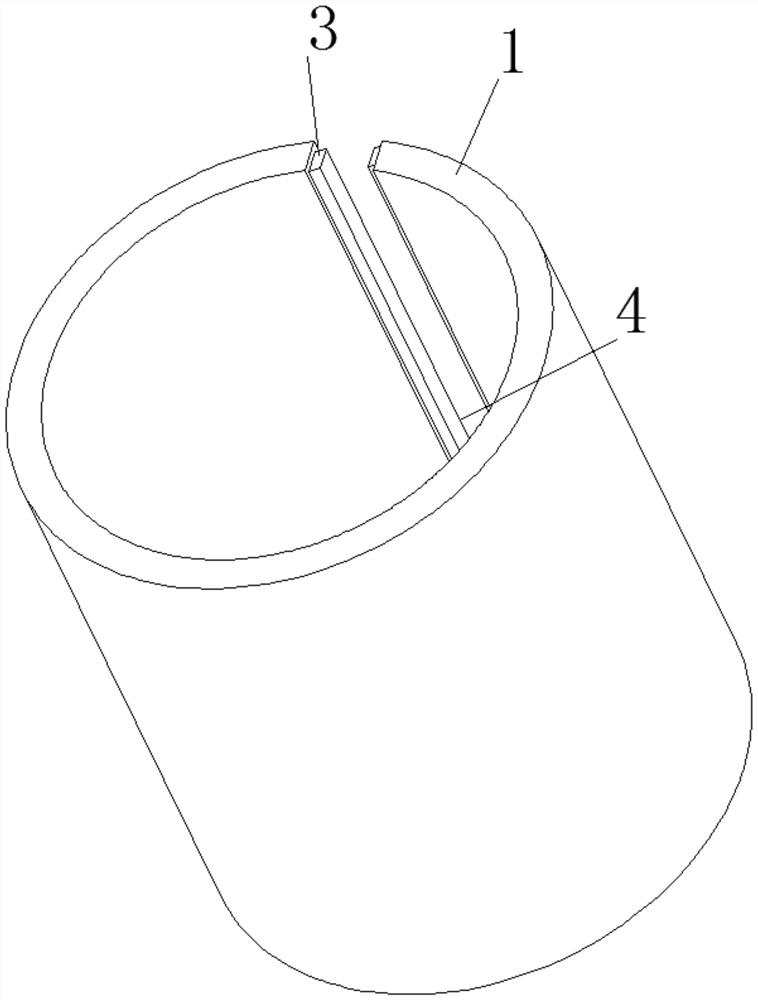

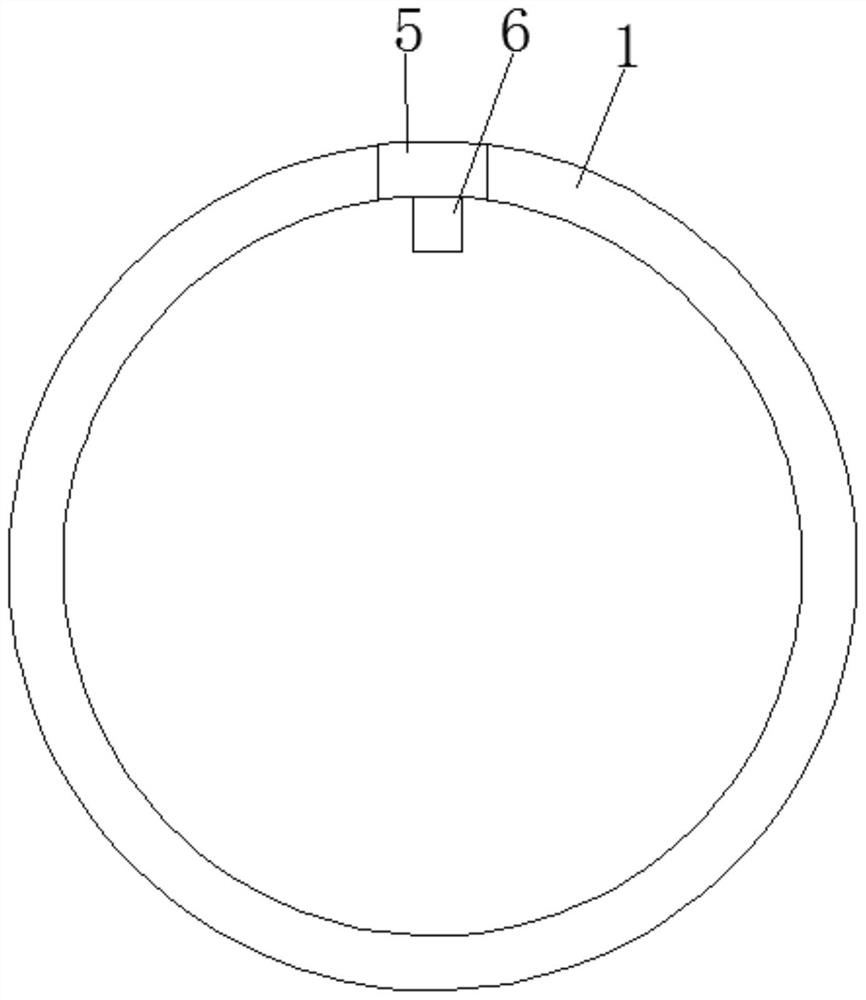

[0021] see Figure 1-4 , this embodiment provides a solder handle fixing steel ring, including a steel ring main body 1, a solder handle 2 is embedded in the middle of the steel ring main body 1, a cutout 4 is opened on one side of the steel ring main body 1, and the inside of the cutout 4 is embedded and installed There is a positioning block 5, the middle part of one side of the positioning block 5 is fixedly installed with a boss 6, and the two sides of the positioning block 5 close to the steel ring main body 1 are provided with mounting grooves 7, and the insides of the two mounting grooves 7 are slidingly connected with mounting platforms 3. The installation platform 3 is welded to the main body 1 of the steel ring.

[0022] In this embodiment, the steel ring main body 1 provides fixed support for the solder handle 2, and the setting of the cutout 4 facilitates the embedded installation of the positioning block 5, and a boss 6 is fixedly installed in the middle of one si...

Embodiment 2

[0024] see figure 1 , made further improvements on the basis of Example 1: the main body of the steel ring 1 is a stainless steel member, the stainless steel itself has good corrosion resistance, and the stainless steel can still maintain its excellent physical and mechanical properties at high temperatures, and its stability Excellent, fixed and tight, can be used for a long time, one end of the solder handle 2 is nested with a rubber ring, anti-slip protection, safe during installation, easy to install quickly, the inner diameter of the steel ring main body 1 is larger than the outer diameter of the solder handle 2 The size is convenient for quick assembly of the steel ring body 1 and the solder handle 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com