Telescopic conveying line

A conveyor line and telescopic technology, applied in the field of retractable conveyor lines, can solve the problems that the conveyor line cannot meet the requirements of use, the length of the conveying plane cannot be adjusted, and the production is slow. The effect of ensuring the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

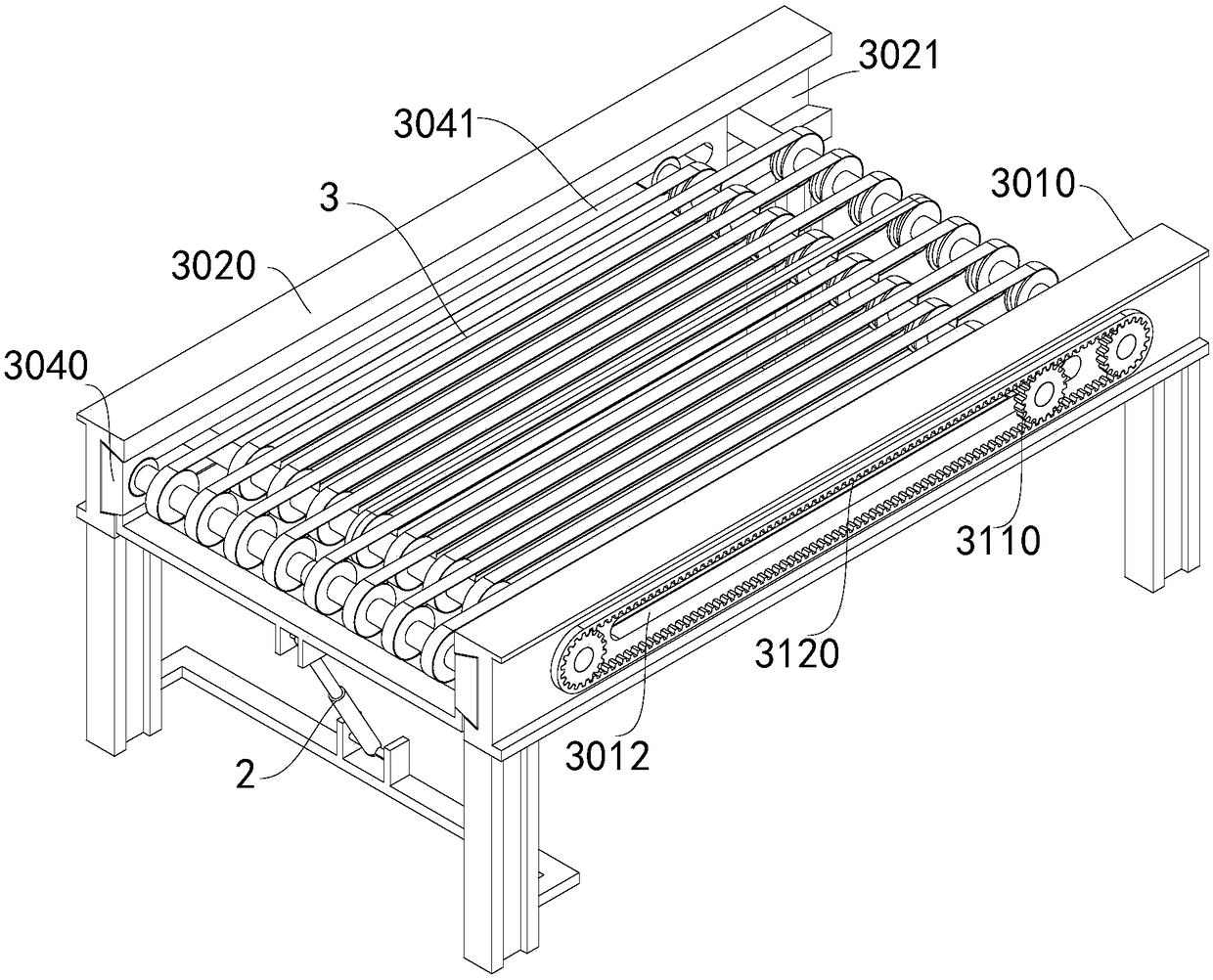

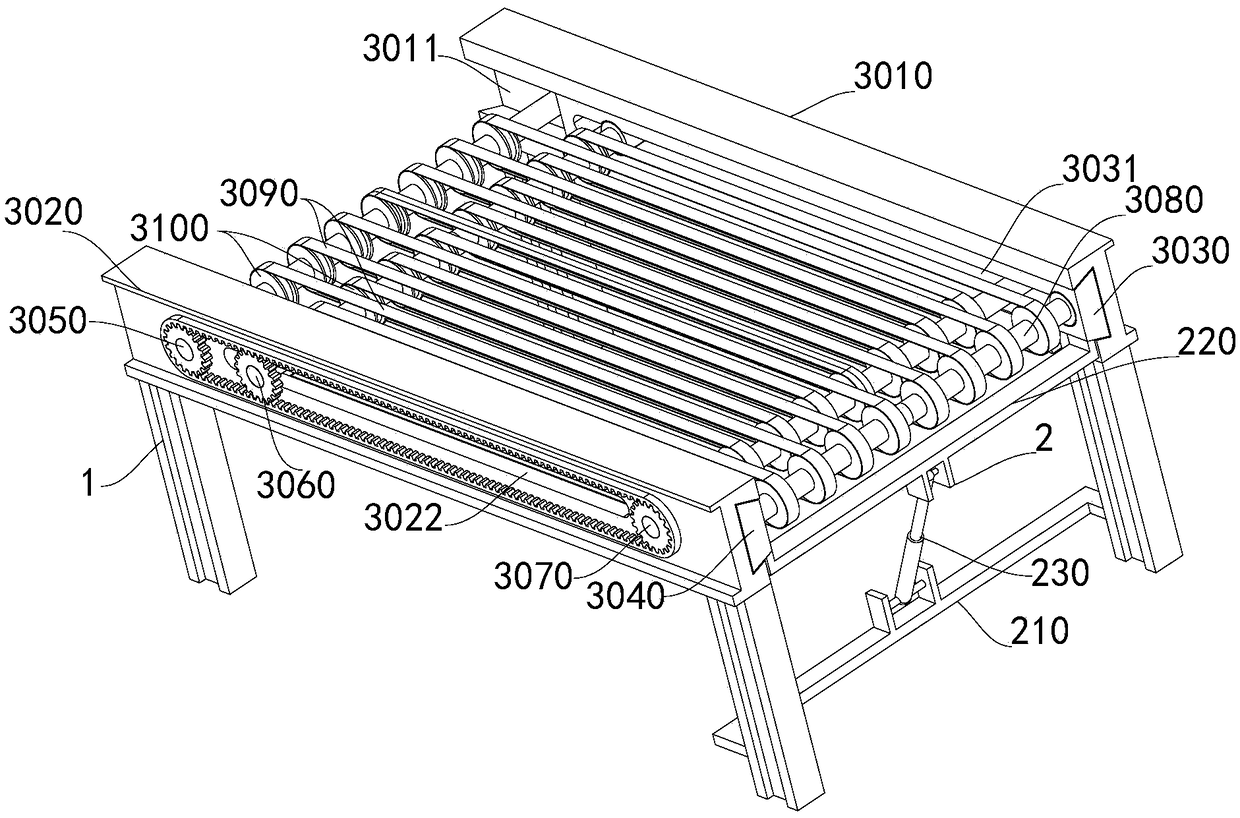

[0021] Such as figure 1 , figure 2 As shown, a telescopic conveying line includes a supporting foot 1, a belt conveying line 3, an automatic telescopic mechanism 2, a driving mechanism and a controller.

[0022] The belt conveyor line 3 includes a first beam 3010, a second beam 3020, a first slider 3030, a second slider 3040, a first shaft 3050, a second shaft 3060, a third shaft 3070, a fourth shaft 3080, and a conveyor belt 3090 , pulley 3100, sprocket 3110 and chain 3120, the first crossbeam 3010 and the second crossbeam 3020 are arranged parallel to each other, and the bottom of the first crossbeam 3010 is provided with a plurality of supporting feet 1, specifically two, three, four A plurality of supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com