Roller clamping mechanism convenient to disassemble and assemble

A clamping mechanism and convenient technology, applied in the directions of transportation and packaging, coiling strips, thin material handling, etc., can solve the problems of small application range, unfavorable quick insertion of bearings, time-consuming and laborious disassembly and assembly, etc., to enhance the application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

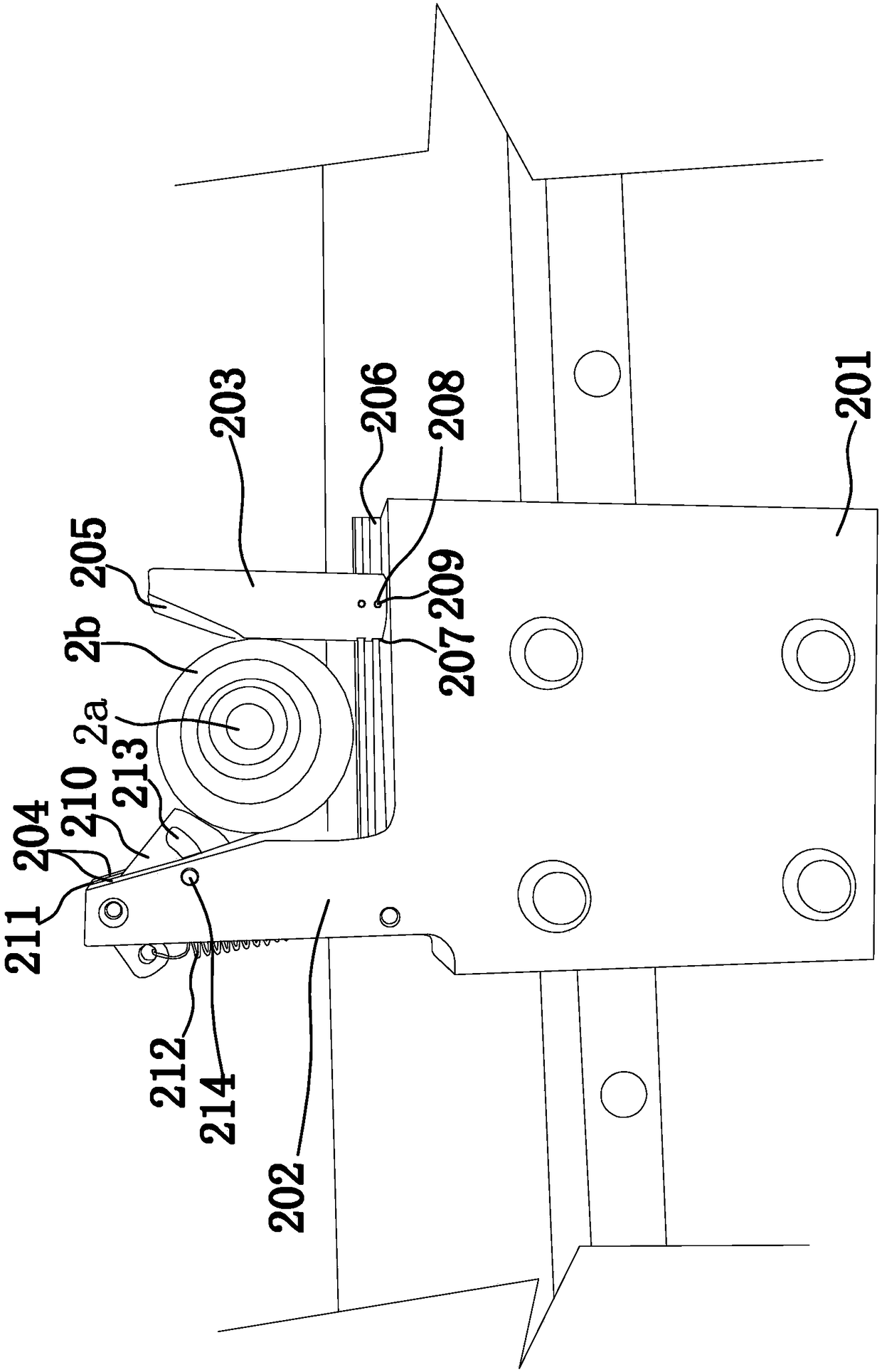

[0015] Such as figure 1 As shown, the clamping mechanism for rollers with convenient disassembly and assembly is arranged on the lateral side of the frame, and includes a fixing seat 201 connected with the frame, and the top of the fixing seat 201 is protrudingly provided with two first chucks arranged at intervals. 202 and the second chuck 203, which are characterized in that: the first chuck 202 is provided with a first inclined clamping surface 204 that is inclined upward and outward, and the upper inner side of the second chuck 203 is provided with a first inclined surface 204 that is inclined upward and outward. Two inclined clamping surfaces 205, the distance between the bottom of the first chuck 202 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com