Automatic oxygen-production generator based on PSA principle

A generator and automatic technology, applied in the direction of oxygen preparation, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of difficult replacement, cleaning of adsorption devices, affecting oxygen production performance, high cost of oxygen production, etc. problem, to achieve the effect of simple structure, convenient operation, and improvement of oxygen purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

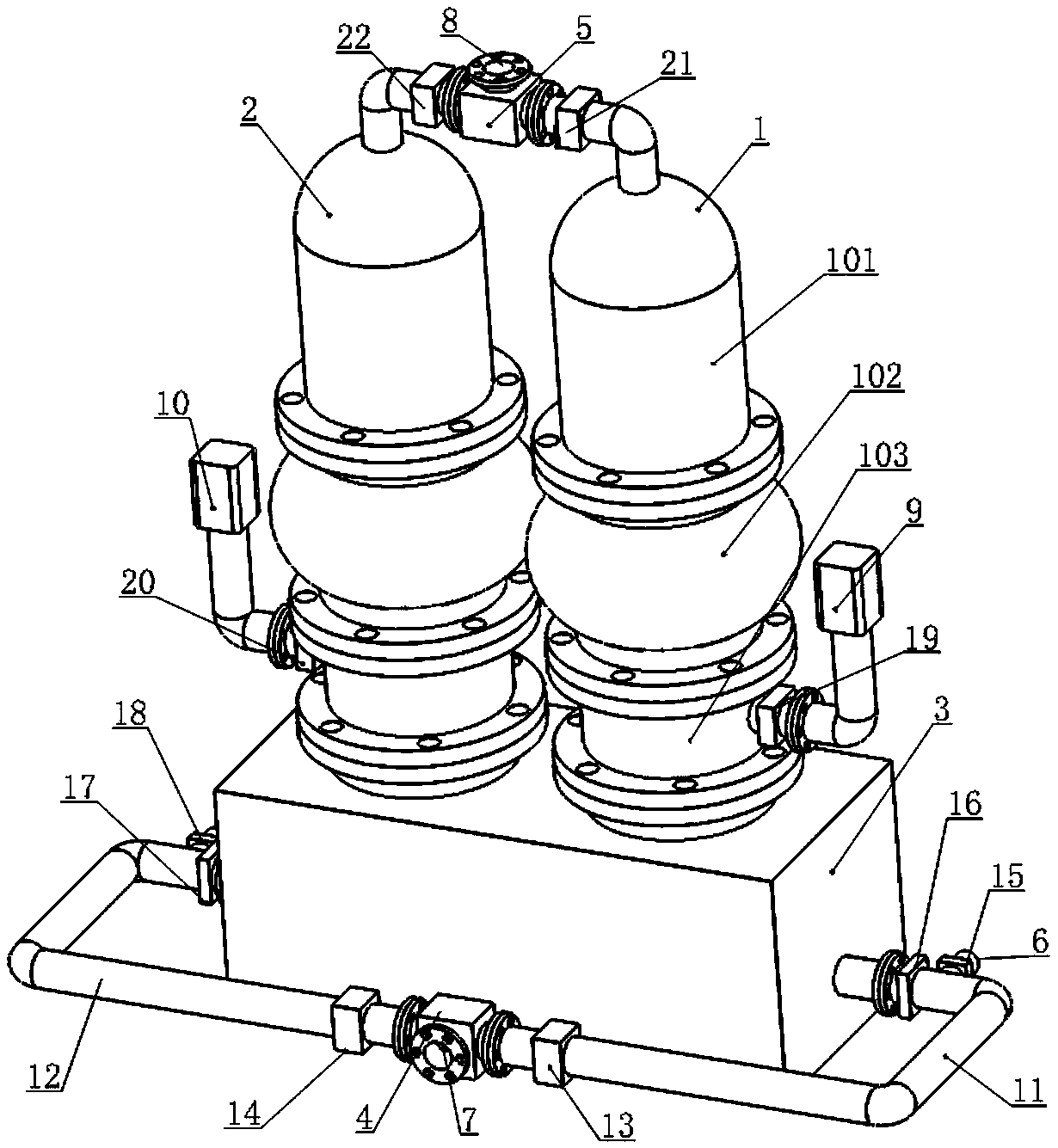

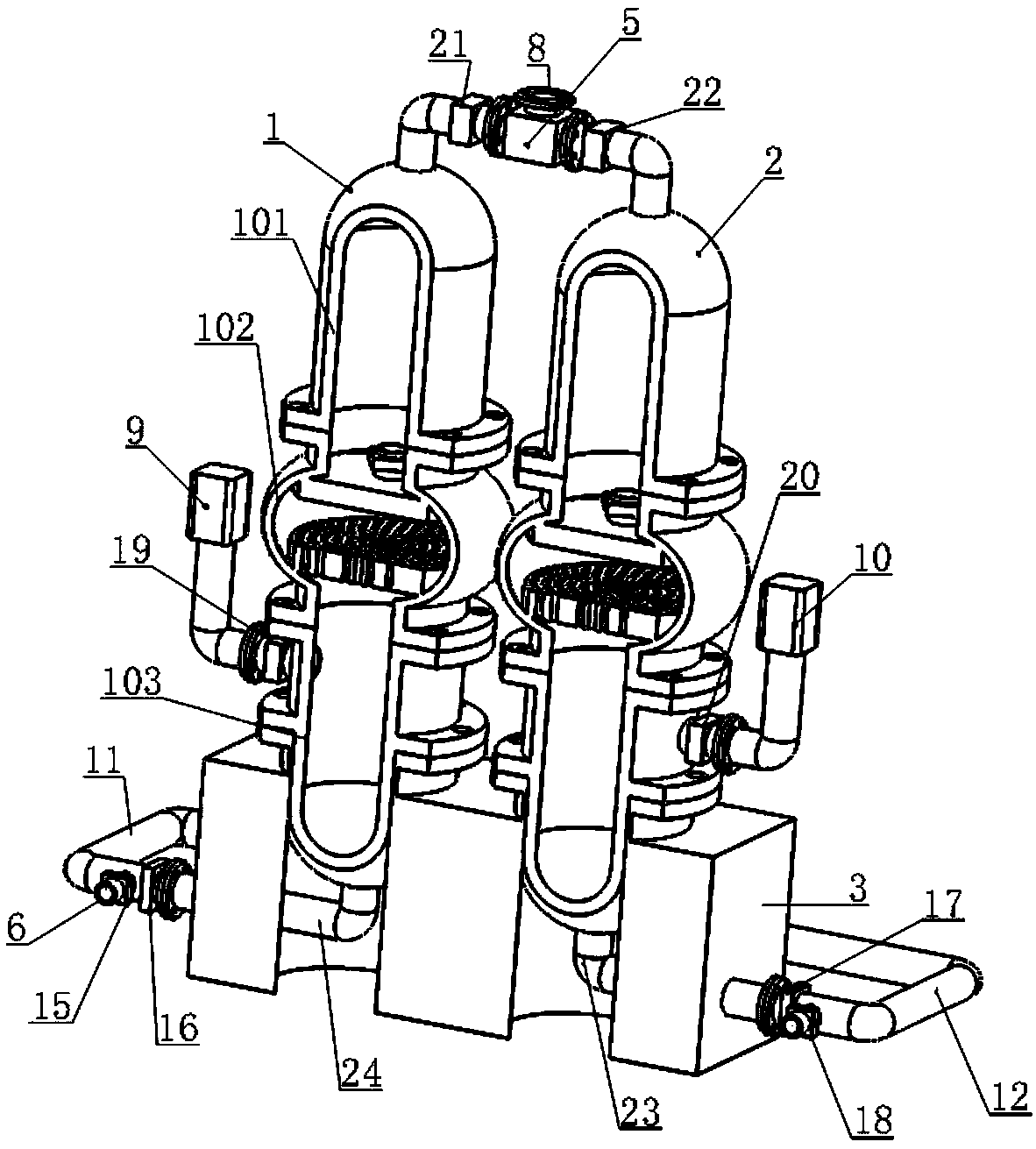

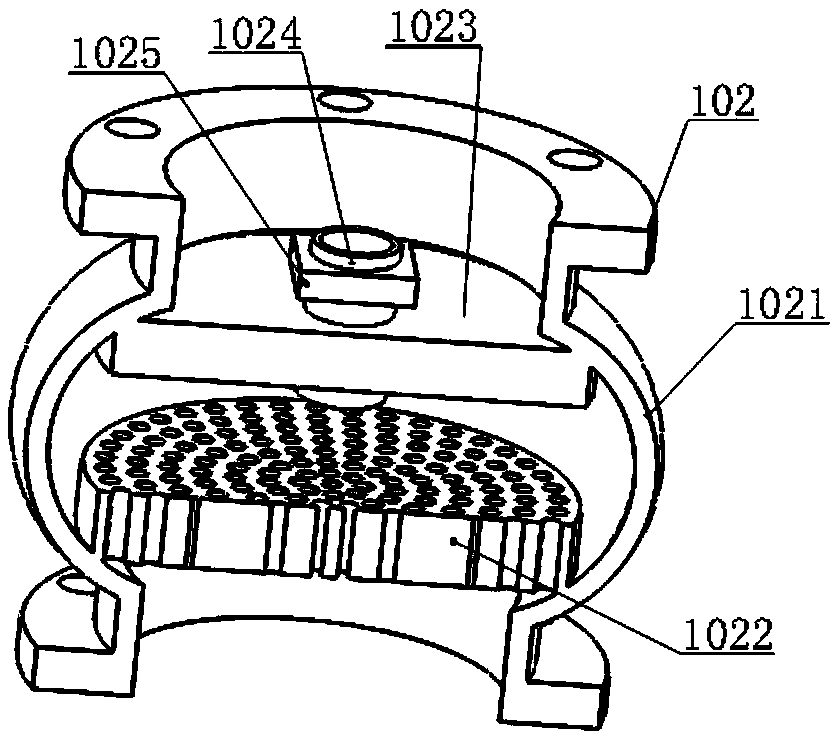

[0015] Such as figure 1 , figure 2 , image 3 As shown, an automatic oxygen generating generator based on the PSA principle in the present invention includes an oxygen generating tower I1, an oxygen generating tower II2, a base 3, a three-way pipe I4, a three-way pipe II5, a nitrogen outlet 6, an inlet Air port 7, oxygen outlet 8, vacuum pump I9, vacuum pump II10, intake pipe I11, intake pipe II12, single solenoid valve I13, one-way solenoid valve II14, single solenoid valve III15, two-way solenoid valve I16, two-way solenoid valve II17, Single solenoid valve Ⅳ18, single solenoid valve Ⅴ19, single solenoid valve Ⅵ20, single solenoid valve Ⅶ21, single solenoid valve Ⅷ22, pipe body Ⅰ23, pipe body Ⅱ24, of which the structure of oxygen generation tower Ⅰ1 and oxygen generation tower Ⅱ2 is consistent, and oxygen generation tower Ⅰ1 Install and fix the oxygen production tower II2 on the base 3, the left and right sides of the base 3 have holes, respectively install the pipe body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com