Fin and heat exchanger provided with same

A technology of heat exchangers and fins, applied in the field of fins and heat exchangers with them, can solve the problems of affecting air flow, affecting the smooth drainage of fins, and excessive condensation water, so as to facilitate drainage and improve heat exchange Efficiency, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

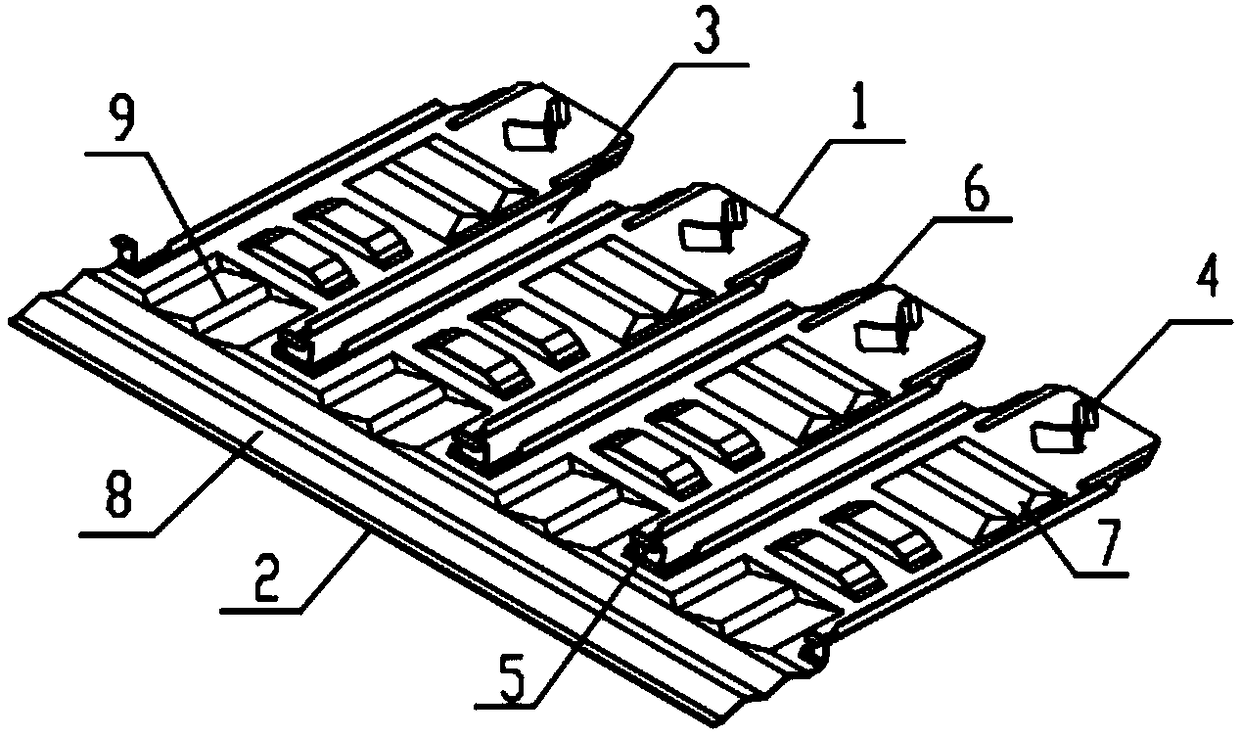

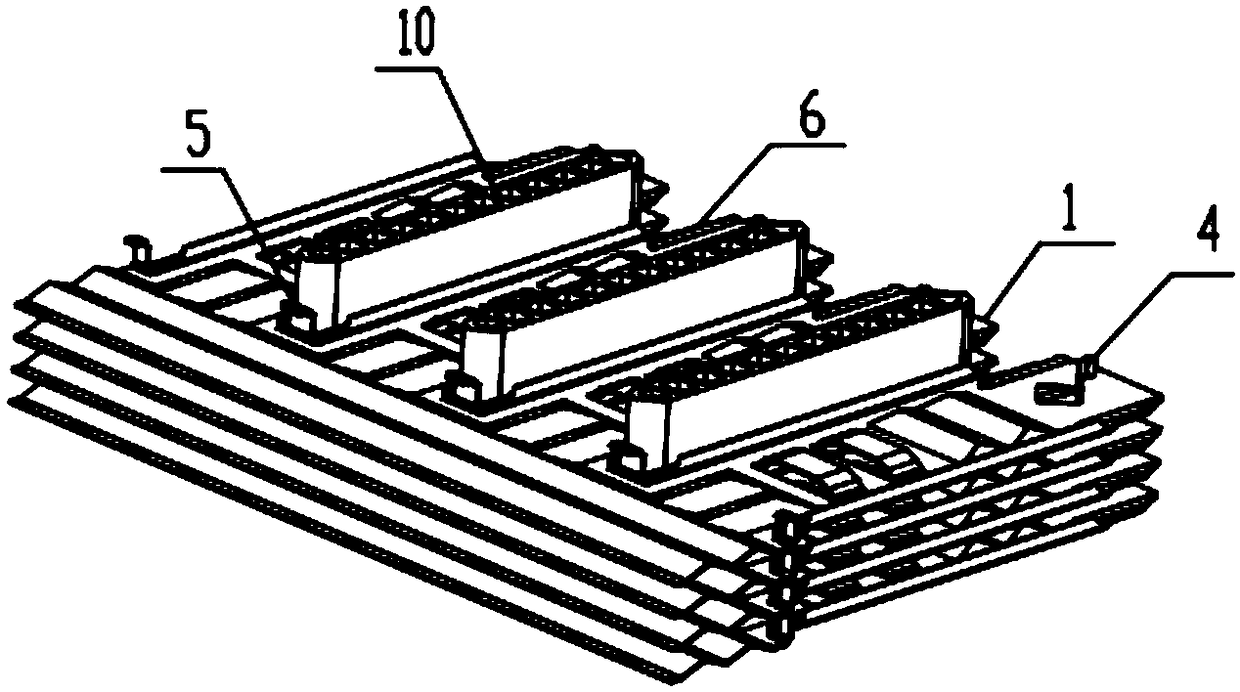

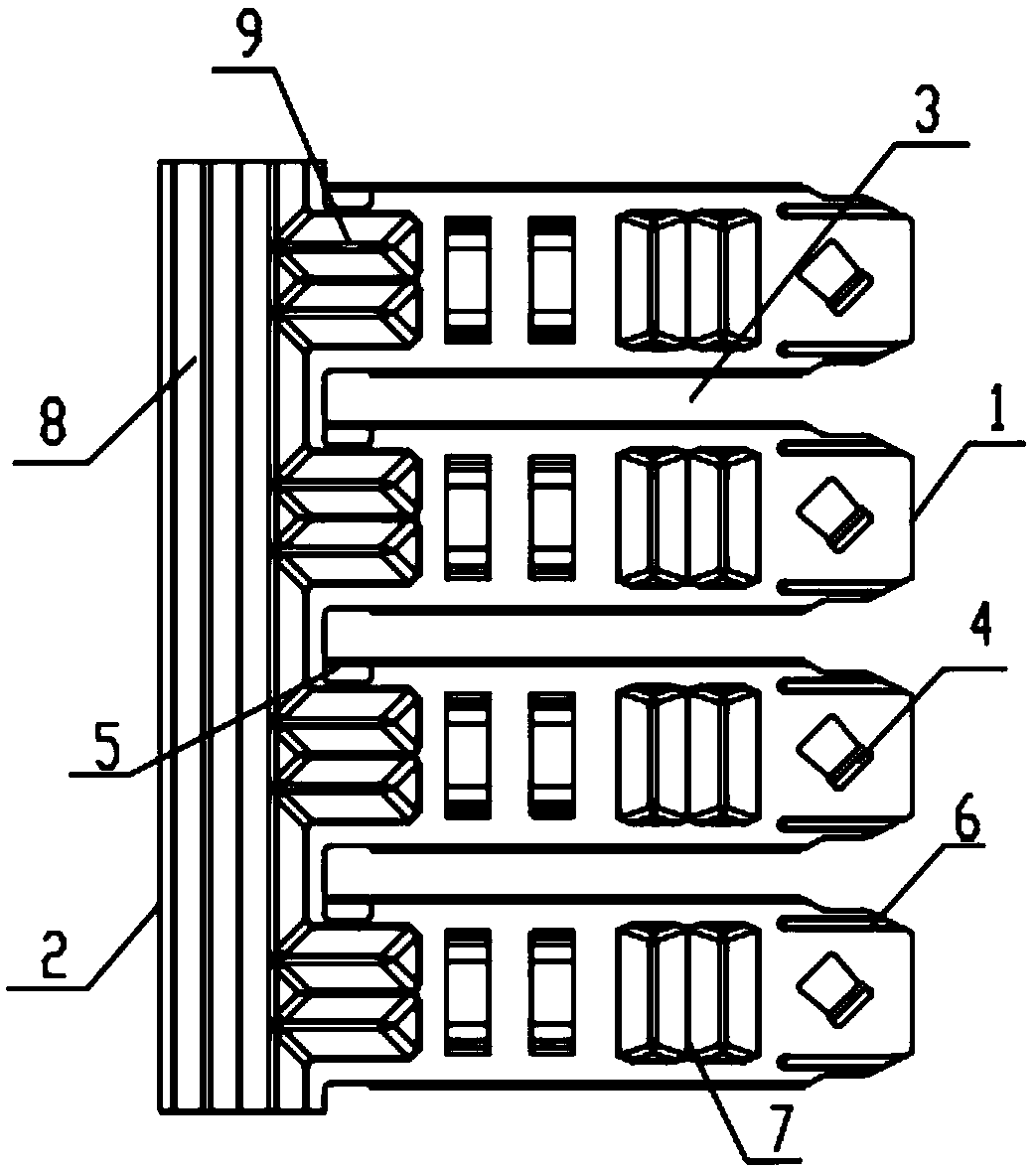

[0035] Please refer to figure 1 -3. This embodiment provides a fin and a heat exchanger including it. One end of the fin is the upwind side 1, the end of the fin opposite to the upwind side 1 is the downwind side 2, and the upwind side 1 is provided with one or more A flat pipe groove 3 extending towards the leeward side 2, the flat pipe groove 3 is used for installing the flat pipe 10;

[0036] The fins are provided with a first positioning structure 4 and a second positioning structure 5 for stacking to form a sheet distance. The first positioning structure 4 is set on the windward side 1, and the second positioning structure 5 is set on the side of the flat tube groove 3 facing the downwind side 2. One side or be arranged in the flat tube groove 3.

[0037] The second positioning mechanism is located at the leeward side 2. After the flat tube slot 3 is installed with the flat tube 10, the second positioning structure 5 is located at the leeward side of the flat tube 10. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com