Method for predicting remaining service life of rolling bearing integrated with KELM

A rolling bearing and life prediction technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as low prediction accuracy, low prediction accuracy, and weak similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

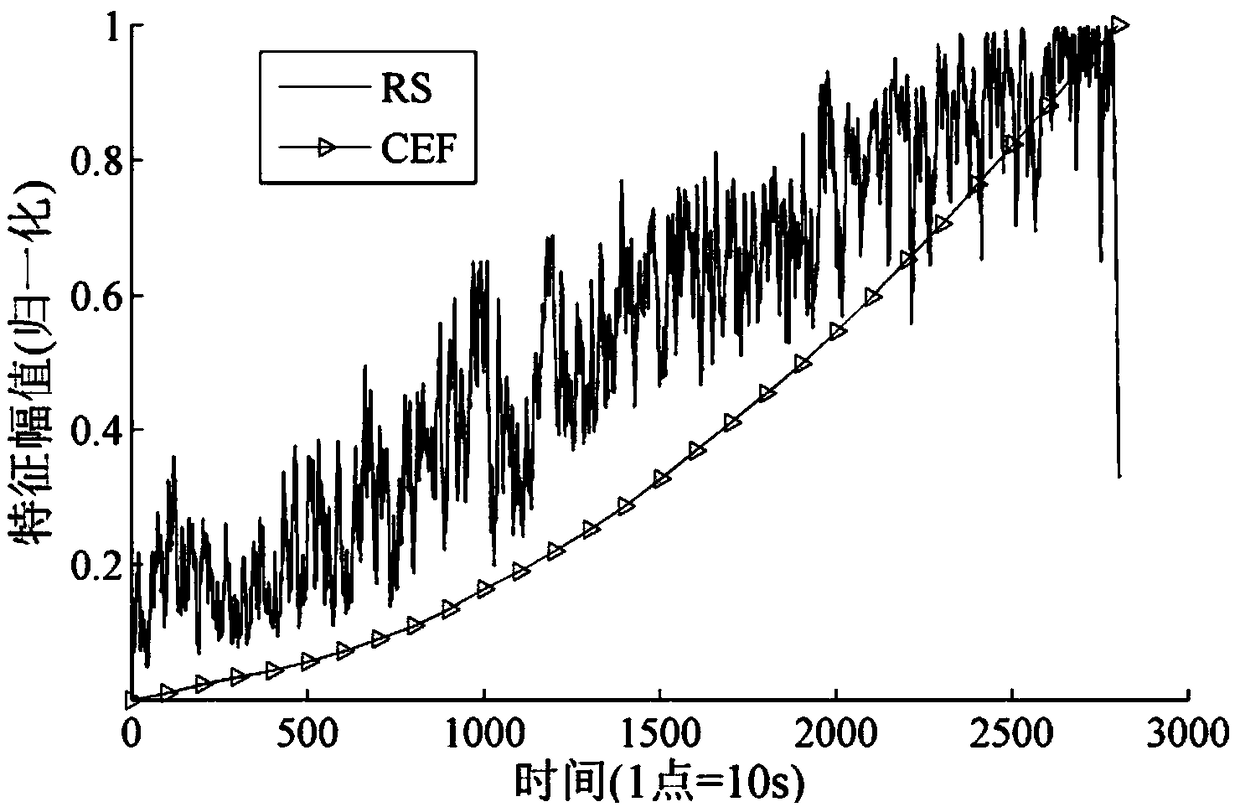

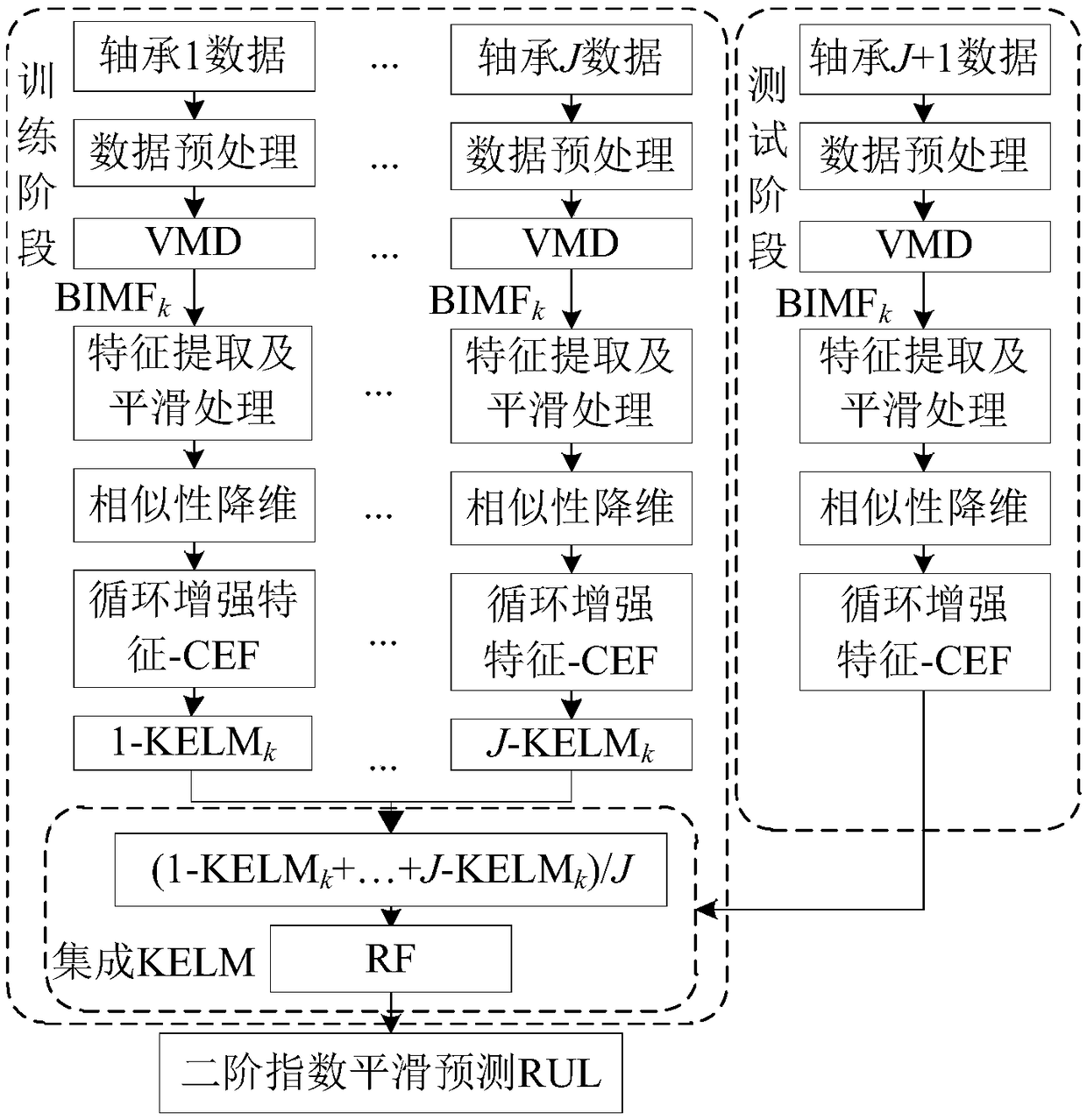

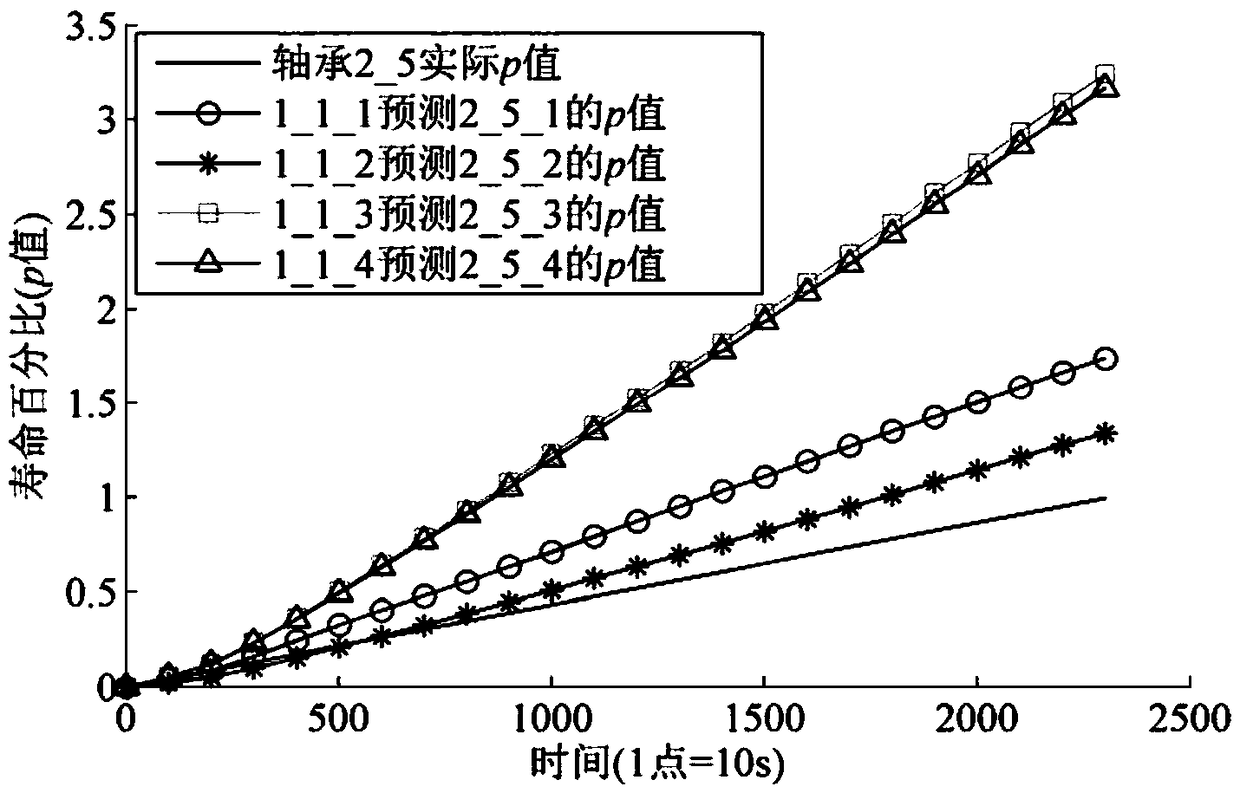

[0034] Such as figure 1 and figure 2 As shown, the specific implementation process of a KELM-integrated rolling bearing remaining service life prediction method described in this embodiment is as follows:

[0035] 1 Feature extraction and dimensionality reduction

[0036] 1.1 Raw vibration signal preprocessing

[0037] The collected original vibration signal is averaged to offset the DC component, and the least square method is used to eliminate the polynomial trend item of the vibration data. Then use the five-point cubic smoothing method to smooth the signal, as shown in formula (1), this method can reduce the high-frequency interference noise of the vibration signal and play a filtering role.

[0038]

[0039] In the formula, y i is the size of sequential sampling values (i=3,4,...,n-2), y i ’ is the size of the data value after smoothing, and n is the total number of data points.

[0040] The five-point cubic smoothing method uses the least square method to fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com