Cutter-free rotary fruit picking machine

A rotary, picking machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of picking unripe fruits, the overall use is not very large, and the work nature is single, and achieves physical strength, Increased compatibility and flexible mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

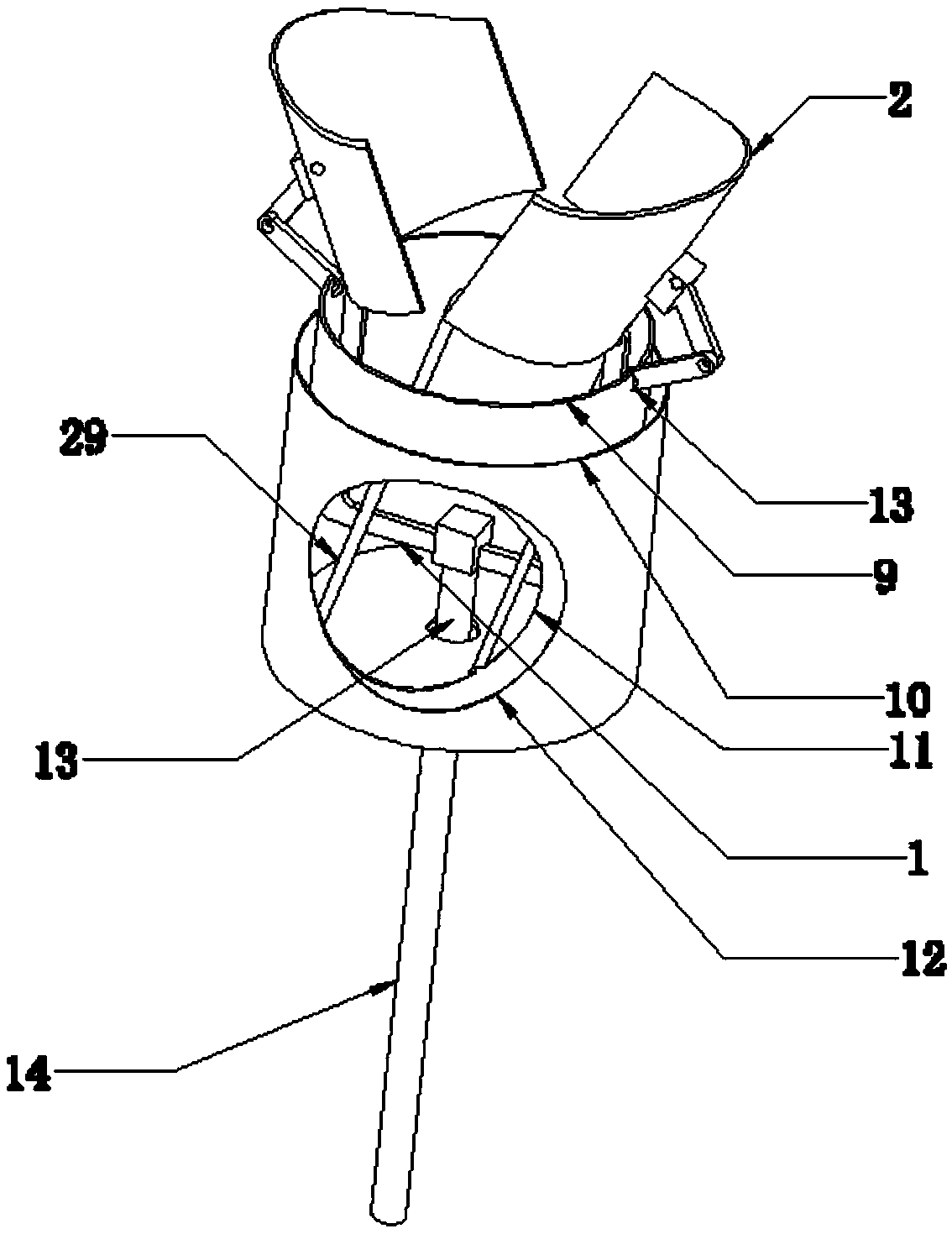

[0037] An automatic knifeless rotary fruit picking machine, comprising a clamping mechanism, a rotating telescopic mechanism and a locking mechanism for locking the clamping mechanism;

[0038] The clamping mechanism includes an inner cylinder 9 and an outer cylinder 10 arranged coaxially, a U-shaped frame 1 driven to move up and down arranged in the inner cylinder 9, and two symmetrically arranged U-shaped frames 1. Two clamping pieces 2 for clamping fruit at the top of the vertical arm, the bottom of each clamping piece 2 is rotated on the corresponding vertical arm through a four-link structure, and a bottom of the U-shaped frame 1 is fixedly arranged. Drive rod 13, the bottom end of the drive rod 13 passes through the bottom of the inner cylinder 9 and the outer cylinder 10, and the corresponding positions on the circumferential side walls of the inner cylinder 9 and the outer cylinder 10 are respectively provided with fruit supply The inner opening 11 and the outer openin...

Embodiment 2

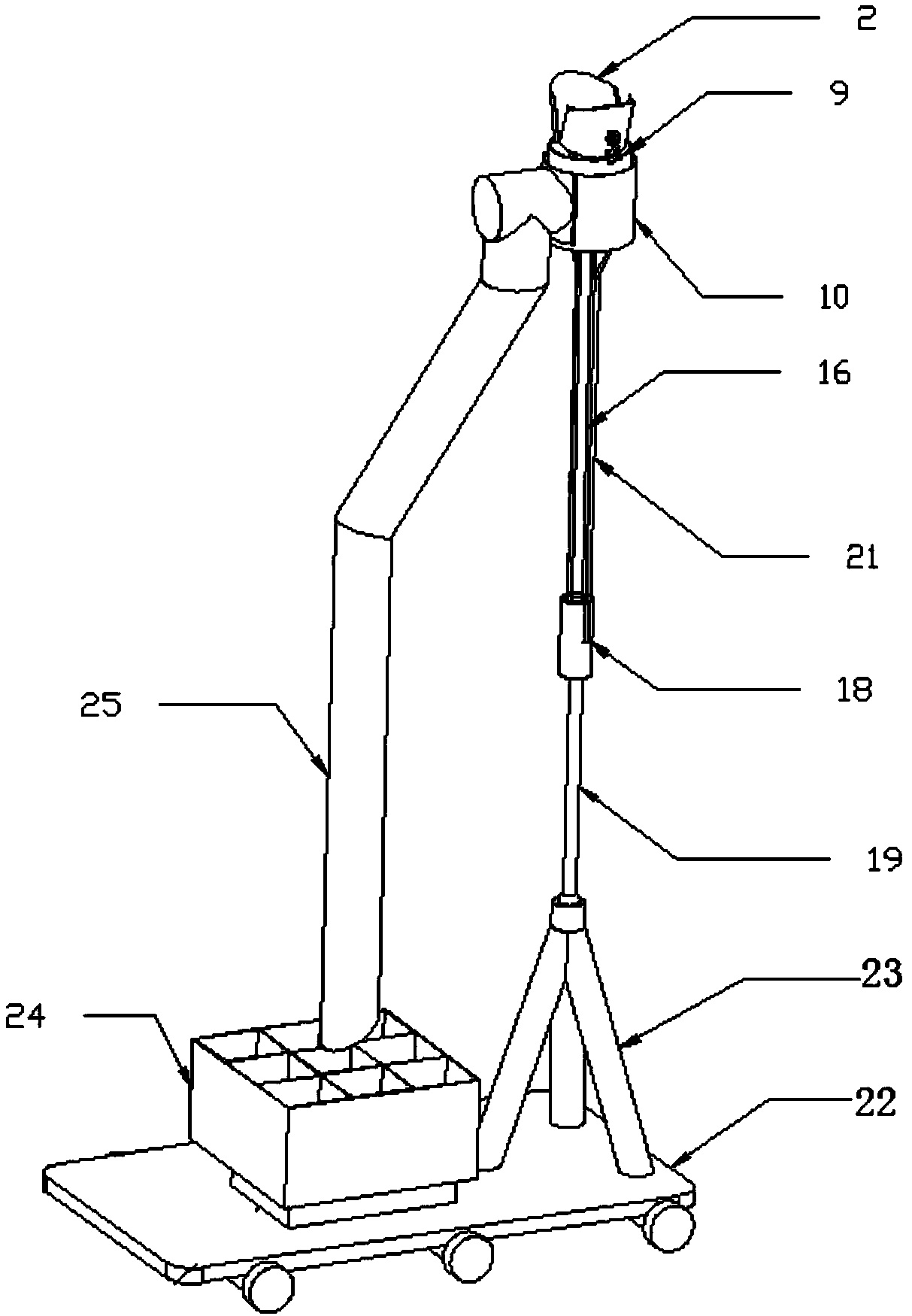

[0047] In this embodiment, on the basis of Embodiment 1, a collection mechanism is added to avoid the time-consuming and labor-intensive problem of holding the pole 19 .

[0048] The fruit picking machine also includes a collection mechanism, and the collection mechanism also includes a trolley 22, the bottom end of the pole 19 is placed on the bearing surface of the trolley 22 by a tripod 23, and one end of the sliding pipe 25 is connected to the bottom of the trolley 22. The outer openings 12 are connected, and the other end extends to the top of the collection box 24 . The picked fruit enters into the collection box 24 placed on the dolly 22 through the downpipe 25 . The tripod 23 itself is light in weight, with a stroke of about 50cm to 139cm. It is convenient to move the position, greatly increases the flexibility of the whole device, solves the problem of less freedom if the pole 19 is fixed on the trolley, and solves the problem of manual handling. The deficiencies tha...

Embodiment 3

[0052] In this embodiment, on the basis of Embodiment 1, the clamping mechanism is further optimized.

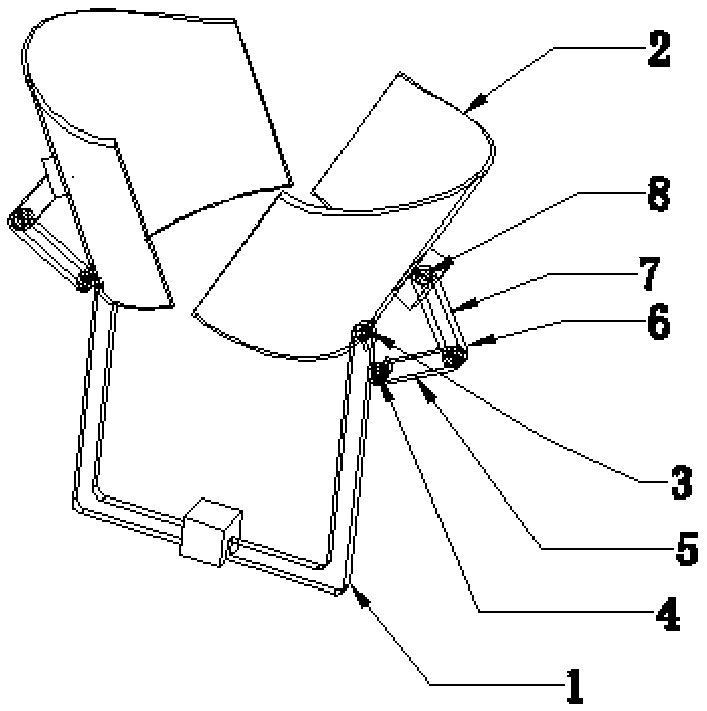

[0053] As a preferred mode, the bottom of the clamping piece 2 is rotatably connected to the top of the U-shaped frame 1 through the first rotating shaft 3, and the middle and upper part of the U-shaped frame 1 is rotatably connected to one end of the lower link 5 through the second rotating shaft 4. , the other end of the lower connecting rod 5 is rotationally connected with one end of the upper connecting rod 7 through the third rotating shaft 6, and the other end of the upper connecting rod 7 is connected with the outer side wall of the clamping piece 2 through the fourth rotating shaft 8 The middle part is rotatably connected, and a notch 13 for supporting the lower link 5 is formed at the top edge of the inner cylinder 9 .

[0054] The upper middle part of the U-shaped frame 1, the lower connecting rod 5, the upper connecting rod 7, and a section from the middle part to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com