Spraying device improving spraying uniformity

A spraying device and a technology for uniformity, which are applied in the field of spraying devices for improving spraying uniformity, can solve problems such as uneven spraying effect, unsightly colored objects, and failure to meet production requirements, and achieve improved spraying uniformity and compact structure. , to create a lightweight and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

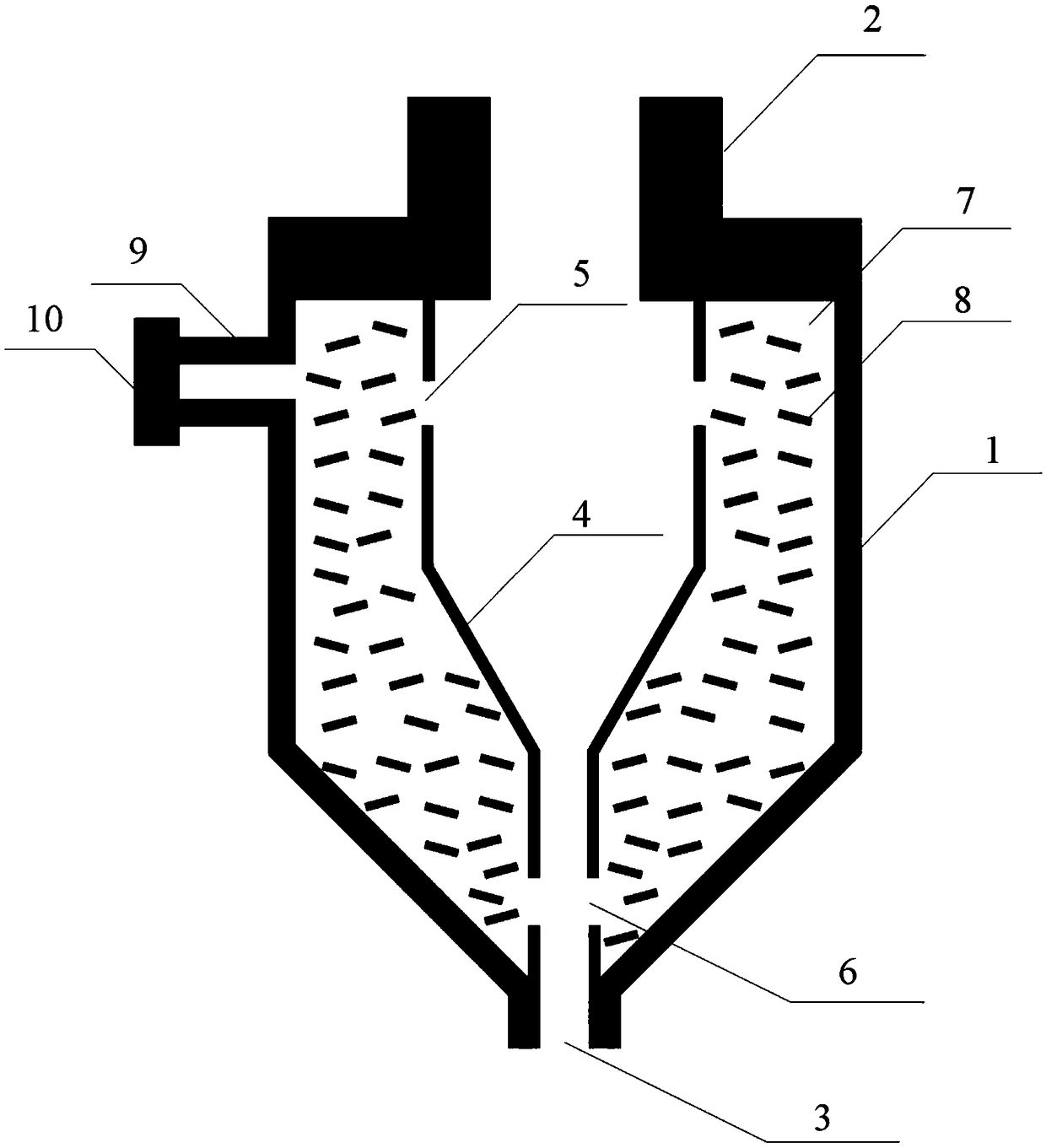

[0021] A spraying device to improve the uniformity of spraying, such as figure 1 As shown, it includes a nozzle housing 1, the top of the nozzle housing 1 is provided with a standard interface 2 for injecting spray liquid, the bottom of the nozzle housing 1 is provided with a nozzle outlet 3, and the inside of the nozzle housing 1 is provided with a goblet-shaped cavity 4 , the cavity 4 communicates with the standard interface 2 and the nozzle outlet 3 respectively, and the interlayer formed between the inner wall of the cavity 4 and the nozzle shell 1 is filled with an ethanol solution 7, and the ethanol solution 7 is evenly dispersed to form a network. small rod-shaped particles 8 with a structure like structure, the upper outer wall of the nozzle housing 1 is provided with an ethanol filling port 9, the ethanol filling port 9 is provided with a sealing cover 10, and the inner wall of the upper large-diameter area of the cavity 4 is provided with several small inlets 5 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com