Installation device and installation method for chemical bolts of equipment bed

A technology of chemical bolts and installation devices, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of not being able to meet the high efficiency and high quality of aircraft assembly equipment, affecting the assembly efficiency and quality of equipment, and large deviations in the verticality of chemical bolts. , to achieve the effects of compact assembly device structure, improved installation consistency, easy portability and on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

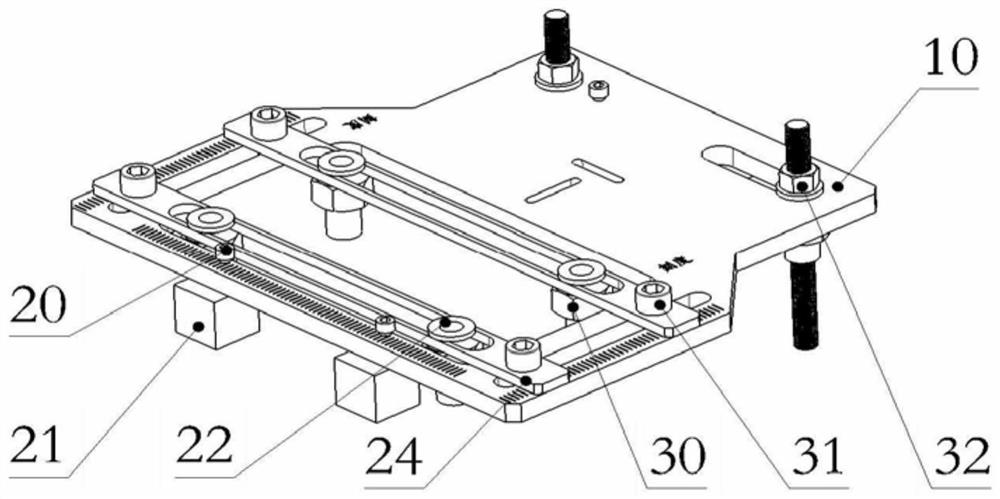

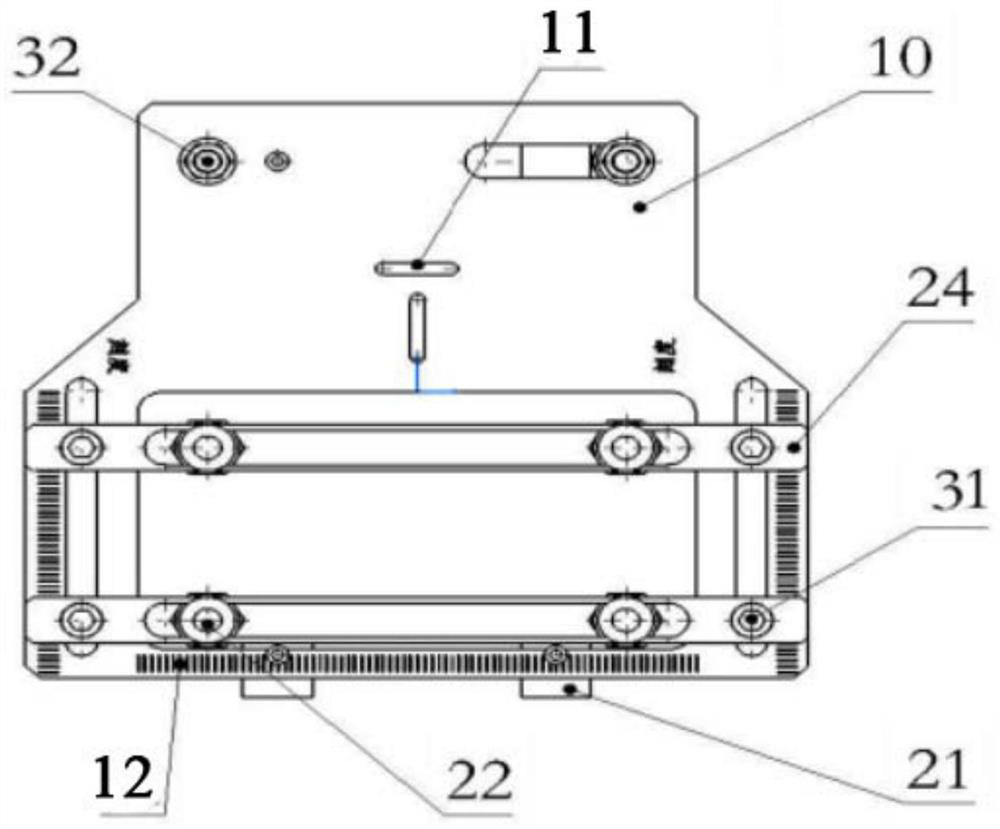

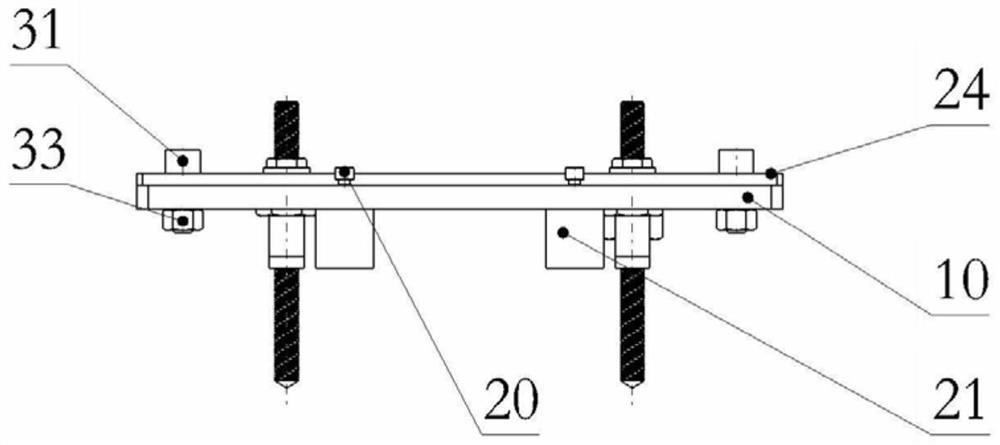

[0036] A device for installing chemical bolts on the bed of equipment in this embodiment mainly consists of bolt positioning components, hole position adjustment components, level adjustment components, device fastening components, guide components and other components. The method includes the following main steps: Pre-installation of bolts, installation and leveling of chemical bolt installation devices, drilling of installation holes, installation and solidification of chemical bolts, etc. The implementation process is described in detail below.

[0037] Such as Figures 1 to 3 As shown, the bolt positioning assembly of the chemical bolt installation device is composed of a positioning plate 10. The positioning plate 10 is provided with a bidirectional level 11 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap