Anti-blue light and anti-fog plexiglass lampshade

A plexiglass and anti-blue light technology, applied in the field of lampshades, can solve the problems that the light source affects the user's color judgment, affects the user's visual clarity, and the total brightness attenuation of the light source, and achieves the effect of continuous anti-fog.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

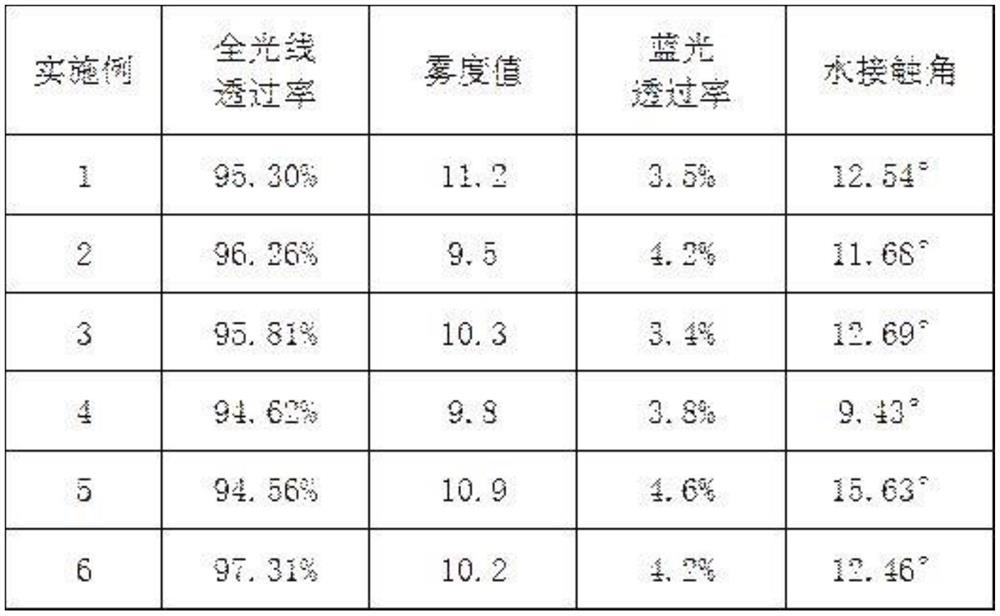

Examples

Embodiment 1

[0026] An anti-blue light and anti-fog plexiglass lampshade, the composition of the plexiglass lampshade is represented by weight percentage: 0.1% coumarin 540, 0.1% silver nanoparticles, 70% methyl methacrylate, 15% acrylic acid, 3 % methacrylic acid, 1.5% β-hydroxyethyl methacrylate, 10% N-methylol acrylamide, 0.5% azobisisobutyronitrile, and the average thickness of the light-transmitting surface of the plexiglass lampshade is 3 millimeters.

[0027] A method for preparing the plexiglass lampshade, the steps are as follows:

[0028] 1) Pre-polymerization: first put the above components in a container and mix them evenly with a stirrer, then keep stirring, heat the pre-polymerization in a water bath at 85-90°C for 0.5-1 hour, the mixture in the above container will form a viscous thin slurry, Then rapidly cool to room temperature to obtain the prepolymer;

[0029] 2) Grouting: Slowly inject the prepolymer into the mold corresponding to the plexiglass lampshade to prevent th...

Embodiment 2

[0033] An anti-blue light and anti-fog plexiglass lampshade, the composition of the plexiglass lampshade is represented by weight percentage: 0.25% coumarin 540, 0.25% silver nanoparticles, 75% methyl methacrylate, 14% acrylic acid, 2 % methacrylic acid, 2% β-hydroxyethyl methacrylate, 5% N-methylolacrylamide, 1.5% azobisisobutyronitrile, the average thickness of the transparent surface of the plexiglass lampshade is 3 mm.

[0034] The method for preparing the plexiglass lampshade is the same as in Example 1.

Embodiment 3

[0036] An anti-blue light and anti-fog plexiglass lampshade, the composition of the plexiglass lampshade is represented by weight percentage: 0.5% coumarin 540, 0.5% silver nanoparticles, 72.5% methyl methacrylate, 12% acrylic acid, 2 % methacrylic acid, 2% β-hydroxyethyl methacrylate, 9% N-methylol acrylamide, 1.5% azobisisobutyronitrile, and the average thickness of the light-transmitting surface of the plexiglass lampshade is 3 millimeters.

[0037] The method for preparing the plexiglass lampshade is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com