Tenon joint shield segment

A technology for mortise-jointing shield pipes and mortise-grooves, which is applied in shaft linings, tunnel linings, underground chambers, etc., can solve problems such as time occupation and difficult operation of tightening bolts, achieve firm bite, speed up shield construction process, The effect of improving splicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

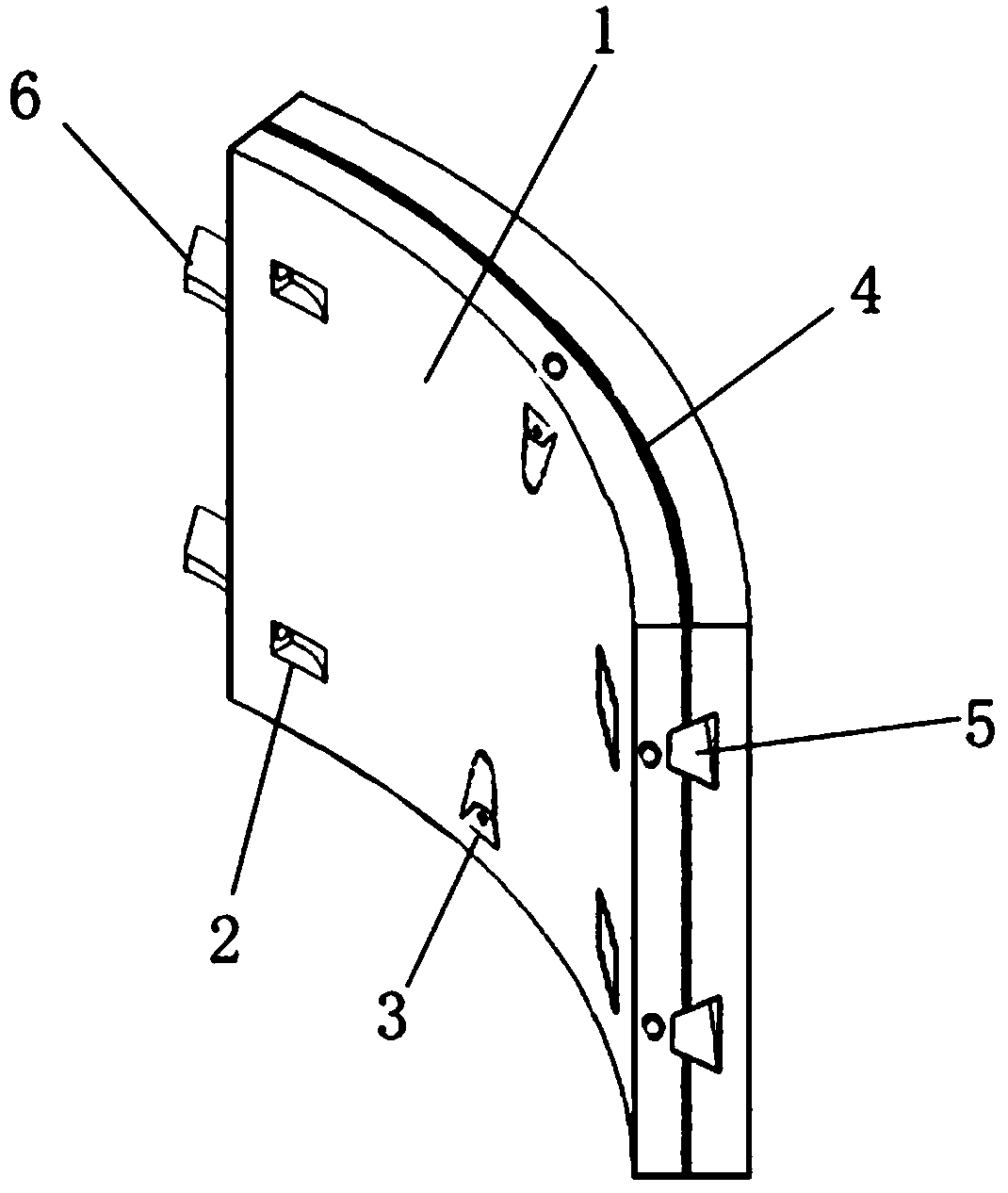

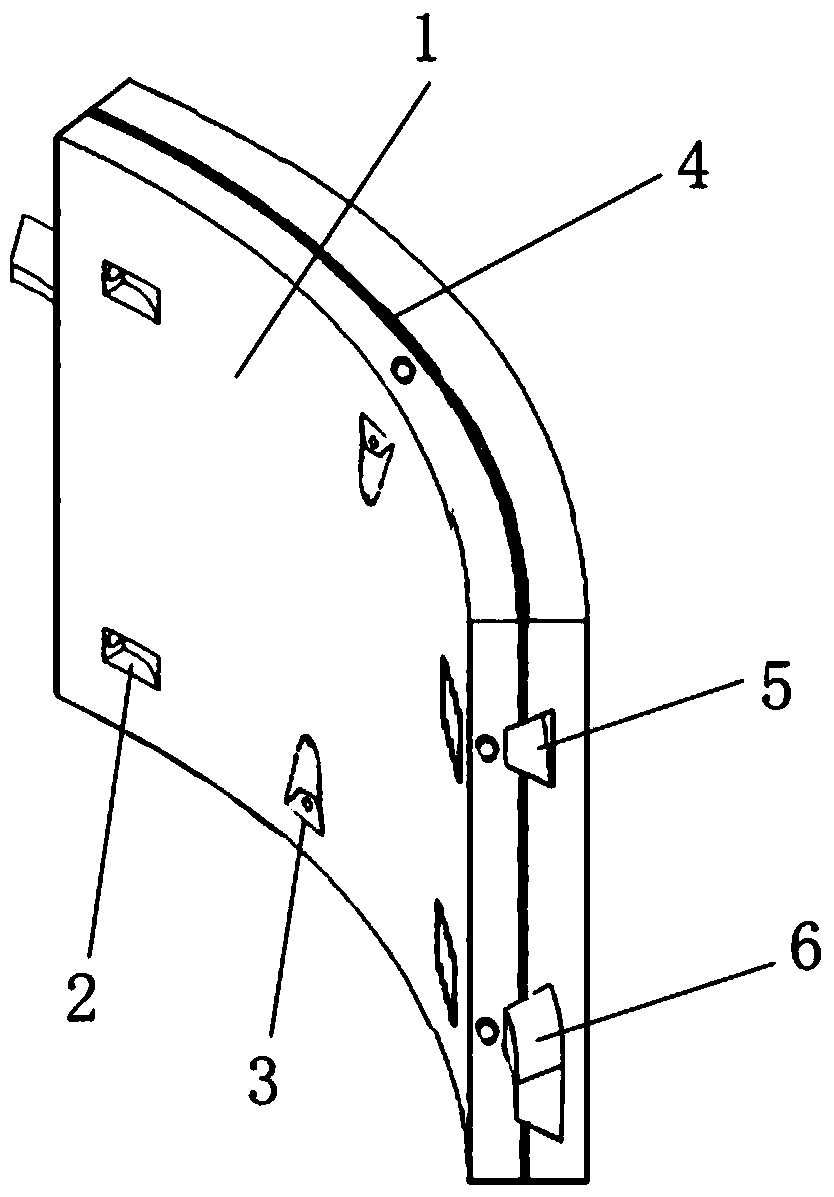

[0026] Such as figure 1 and figure 2 As shown, a mortise-jointed shield segment includes an arc-shaped sheet body 1 , a circumferential screw groove 2 , a longitudinal screw groove 3 , and a sealing strip 4 . One end of the arc-shaped sheet body 1 has two tenons 6, and the other end has two tenon grooves 5. same curvature. When the shield segment is installed, the tenon 6 is inserted into the tenon groove 5. Since the curvature of the tenon 6 and the tenon groove 5 is the same as that of the arc-shaped sheet body 1, the arc-shaped circumferential spirals at both ends of the two arc-shaped sheet bodies 1 The groove 2 is automatically aligned, and the arc bolt can pass through the circumferential screw groove 2 smoothly, which greatly reduces the difficulty of aligning the circumferential screw groove 2, improves the connection efficiency of the circular upward arc bolt, and speeds up the shield tunneling process.

Embodiment 2

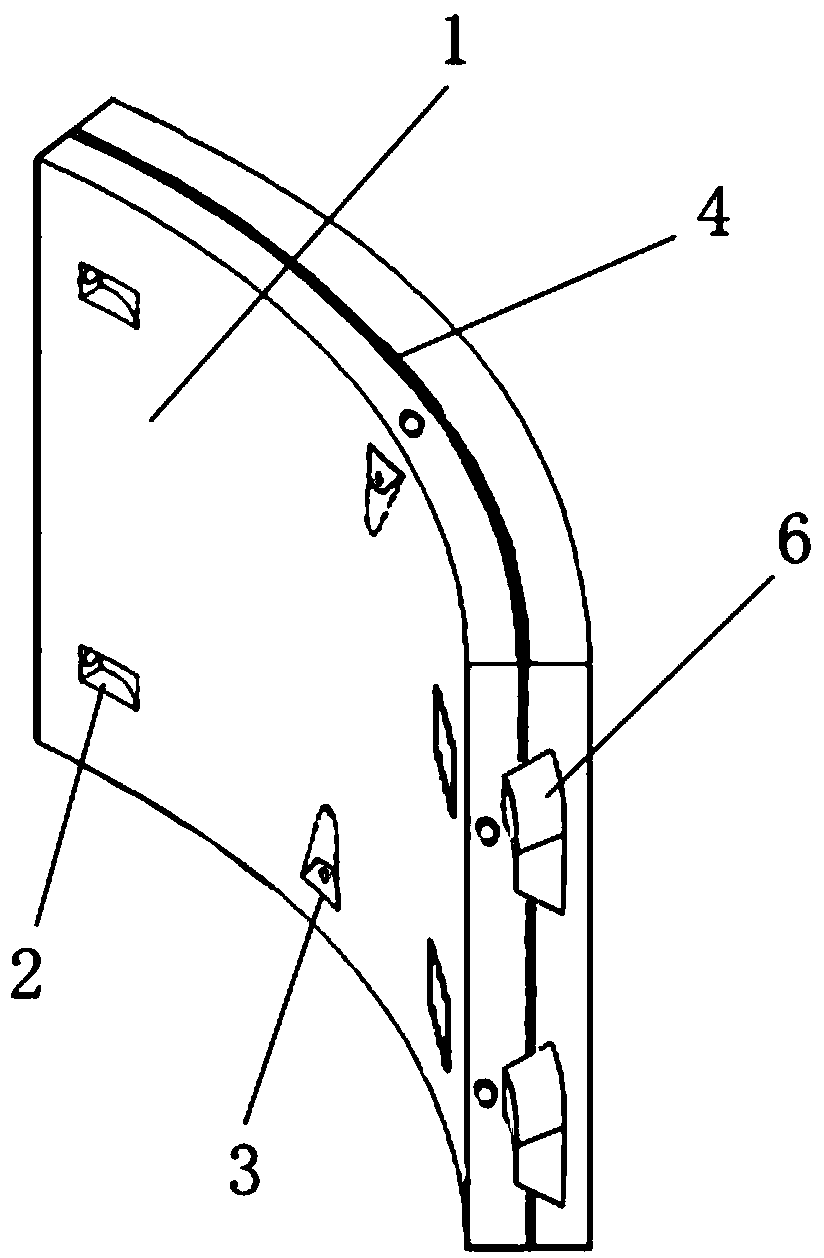

[0028] Such as image 3 As shown, a mortise-joint shield segment includes an arc-shaped sheet body 1, a circumferential screw groove 2, a longitudinal screw groove 3, and a sealing strip 4. Both ends of the arc-shaped sheet body 1 have a tenon groove 5 and a Tenon 6. Both the tenon head 6 and the tenon groove 5 are arc-shaped tenon grooves, and the curvature of the tenon head 6 and the tenon groove 5 is the same as that of the arc-shaped sheet body 1 . When the shield segment is installed, the mortise 5 and the tenon 6 of the two arc-shaped pieces 1 are inserted into each other. Since the curvature of the tenon 6 and the tenon 5 is the same as that of the arc-shaped piece 1, the two arc-shaped pieces The arc-shaped circumferential screw grooves 2 at both ends of 1 are automatically aligned, and the arc-shaped bolts can pass through the circumferential screw grooves 2 smoothly, which greatly reduces the difficulty of aligning the circumferential screw grooves 2 and improves th...

Embodiment 3

[0030] On the basis of Example 1, if staggered splicing is used, it is only necessary to shift the position of the longitudinal screw groove to both ends when prefabricating the shield segment, and at the same time move the tenon joint to the side of the arc-shaped sheet, To improve the butt joint efficiency of the two arc-shaped sheets in the longitudinal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com