Lithium iron phosphate/multilayer graphene composite material and its preparation method and lithium ion battery using it

A multi-layer graphene, lithium-ion battery technology, applied in the field of materials, can solve the problems of lithium iron phosphate size uniformity, distribution uniformity, etc. to be improved, and achieves improvement of low electronic conductivity, strong metal ion load capacity, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] In the prior art, the preparation method of the composite of lithium iron phosphate and graphene is to add iron ions, lithium ions and phosphate ions together in a one-step method, and then chemical co-deposition to synthesize the precursor. The precursor distribution of this method is difficult to evenly distribute on the graphene surface, so the final lithium iron phosphate distribution is not uniform.

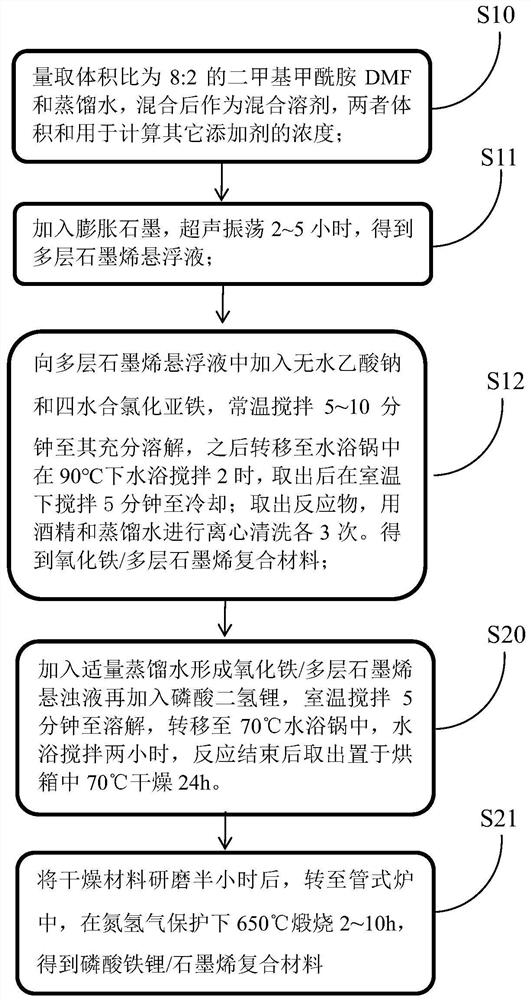

[0037] In order to solve the above-mentioned technical problems, the present invention discloses a preparation method of a composite material of lithium iron phosphate / multilayer graphene, comprising the following steps:

[0038] Step S1, prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com