Container that opens and closes automatically

An automatic opening and closing, container technology, applied in the field of seasoning bottles, can solve the problems of inability to automatically open and close, unsanitary, easy to deteriorate, etc., and achieves the effects of low cost, simple structure, and reduced probability of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

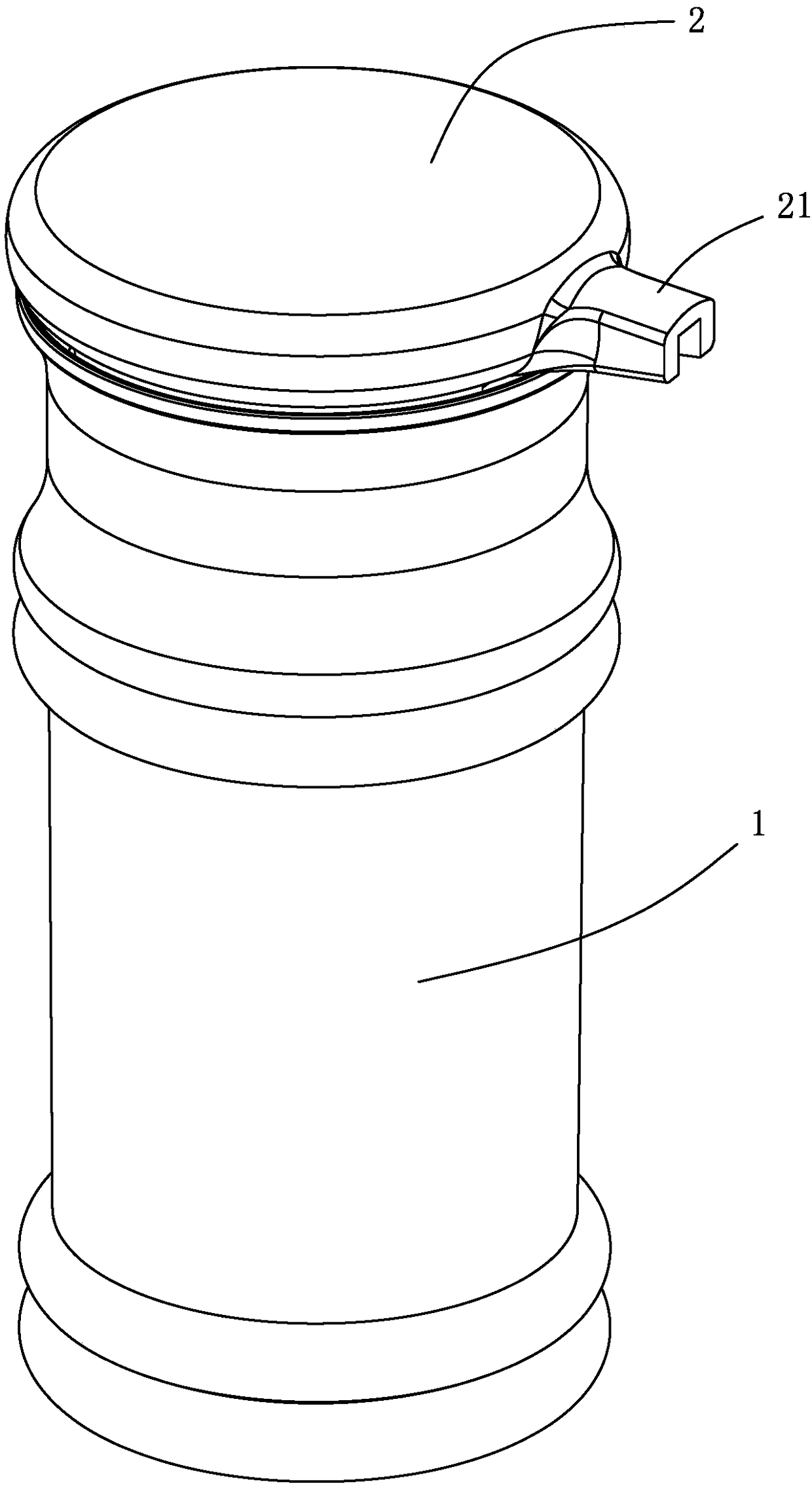

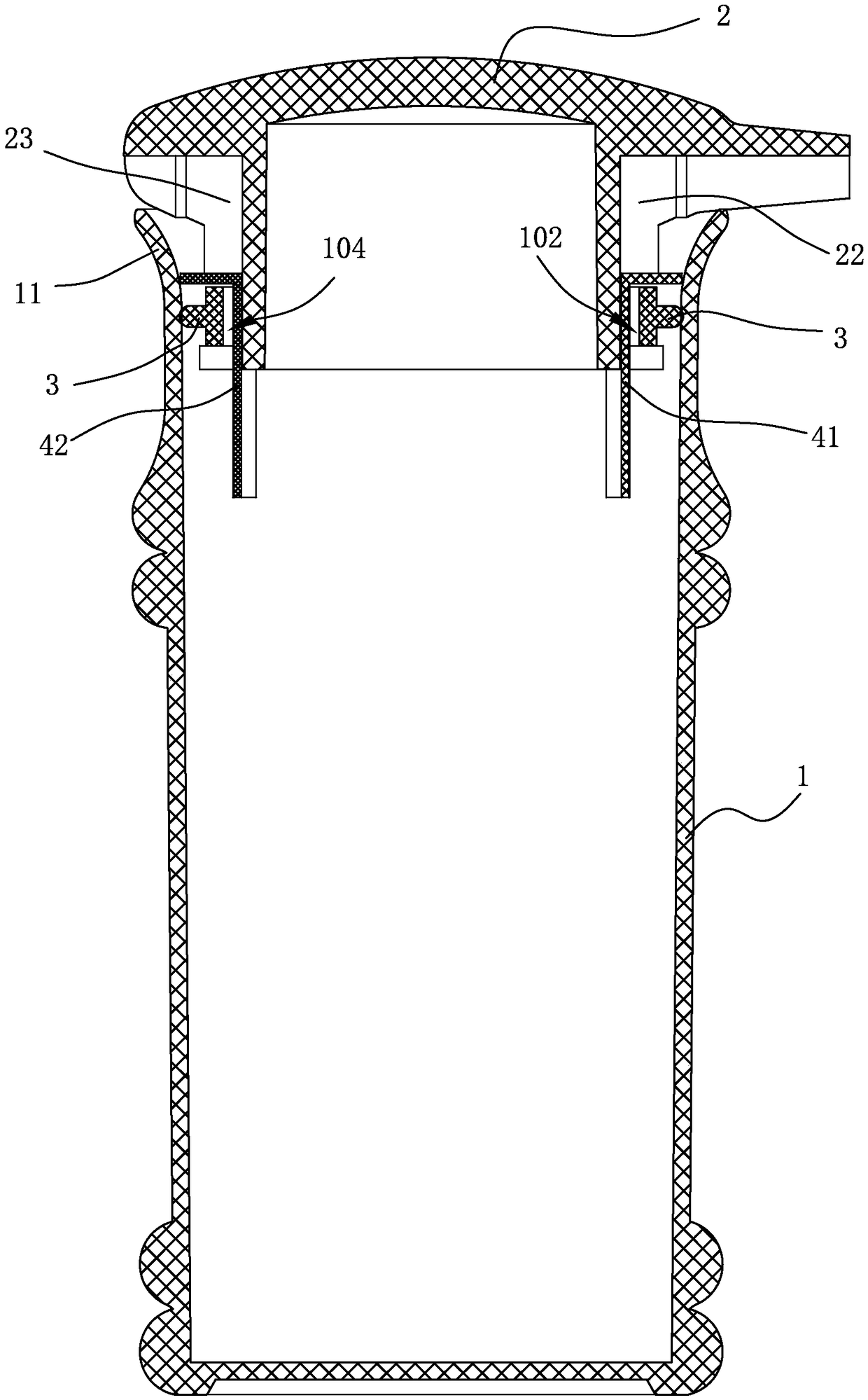

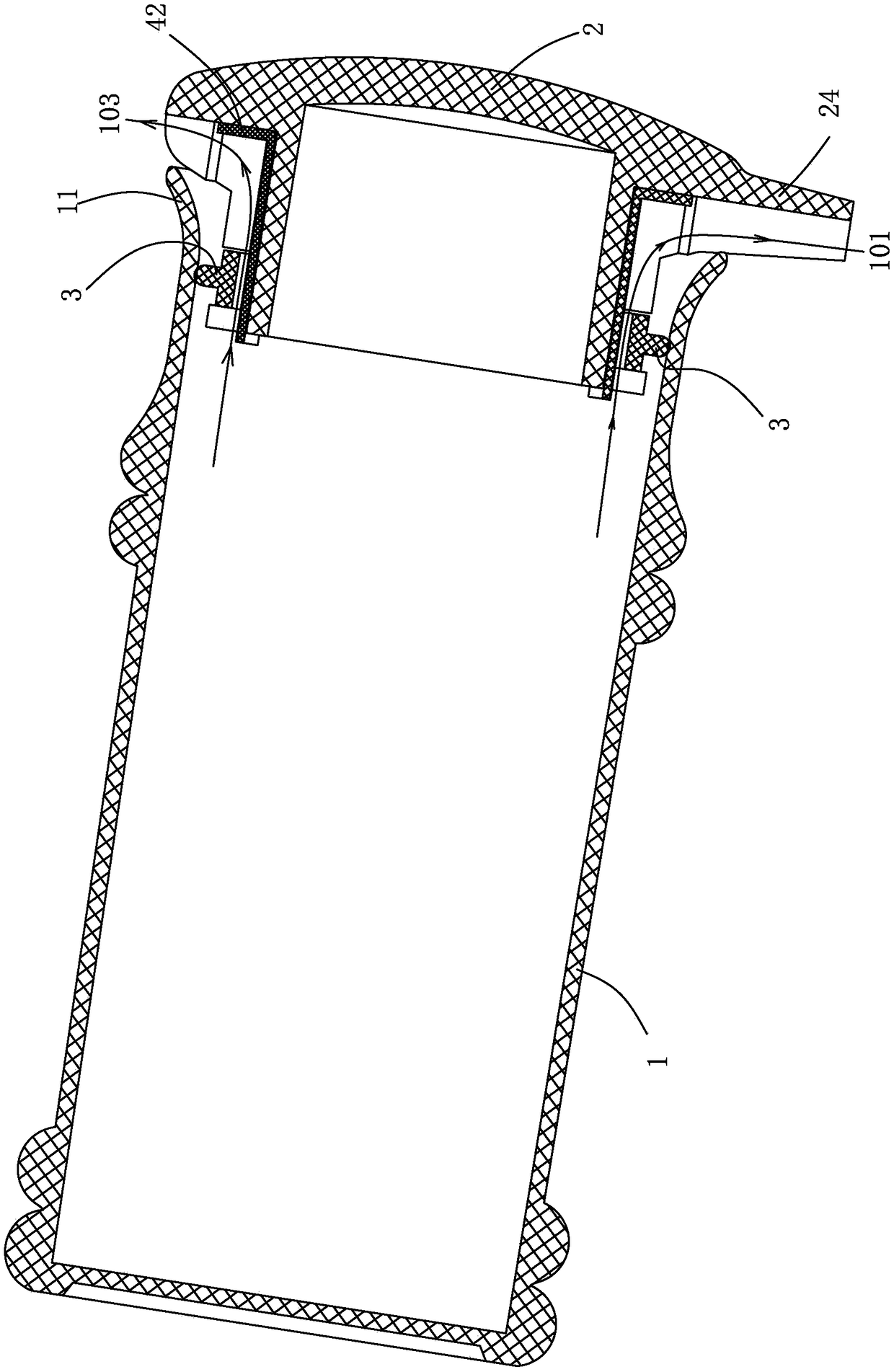

[0038] Such as Figure 1 to Figure 7 As shown, a container that can be opened and closed automatically in this embodiment includes a hollow bottle body 1 with an open upper end and a bottle cap 2 connected to the opening of the bottle body 1. The upper end opening of the bottle body 1 is provided with a gradually The bell-shaped connecting edge 11 extends outward, and the bottle cap 2 is provided with an annular positioning groove 21 along the horizontal direction, and a sealing ring A3 is connected inside the annular positioning groove 21, and the outer surface of the sealing ring A3 is The side is sealed and connected with the connecting edge 11 of the bottle body 1. The bottle cap 2 is vertically provided with a liquid outlet groove 22 and an air supply groove 23 passing through the annular positioning groove 21. The liquid outlet groove 22 and the bottle A liquid outlet channel 101 is formed between the inner side walls of the body 1, and a liquid outlet 102 communicating ...

Embodiment 2

[0042] Such as Figure 8 to Figure 12 As shown, a container that can be opened and closed automatically in this embodiment includes a hollow bottle body 1 with an open upper end and a bottle cap 2 connected to the opening of the bottle body 1. The upper end opening of the bottle body 1 is provided with a gradually The bell-shaped connecting edge 11 extends outward. The bottle cap 2 is provided with a liquid outlet groove 22 and an air supply groove 23 along the vertical direction. The liquid outlet channel 101, the liquid outlet tank 22 is movable with a liquid outlet valve piece B51 for opening and closing the liquid outlet channel 101, and the air supply channel 103 is formed between the air supply tank 23 and the inner wall of the bottle body 1 , the air supply tank 23 is provided with an air supply valve plate B52 for opening and closing the air supply channel 103, and the lower end of the liquid outlet tank 22 is provided with a limit edge A221 for limiting the movement o...

Embodiment 3

[0046] Such as Figure 13 to Figure 18 As shown, a container that can be opened and closed automatically in this embodiment includes a hollow bottle body 1 with an open upper end and a bottle cap 2 connected to the opening of the bottle body 1. The upper end opening of the bottle body 1 is provided with a gradually Outwardly extending the connecting edge 11 in the shape of a bell mouth, the bottle cap 2 is provided with an annular positioning groove 21 along the horizontal direction, and the sealing ring B6 made of elastic material is connected in the described annular positioning groove 21, so that The outer edge of the sealing ring B6 is sealed and connected with the connecting edge 11 of the bottle body 1, and the inner edge of the sealing ring B6 is sealed and connected with the bottle cap 2, and the bottle cap 2 is provided with a penetrating annular positioning The liquid outlet groove 22 and the air supply groove 23 of the groove 21, the liquid outlet channel 101 is for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com