Steamer dehumidification and sterilization control method and system

A control method and technology of the steamer, which are applied in the control/regulation system, humidity control, non-electric variable control and other directions, can solve the problems of closed loop without detection feedback, incompleteness, fan noise pollution, etc. Mildew, avoid odor and mildew, avoid the effect of cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to facilitate the understanding of those skilled in the art, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings, which cannot be used to limit the protection scope of the embodiments of the present invention.

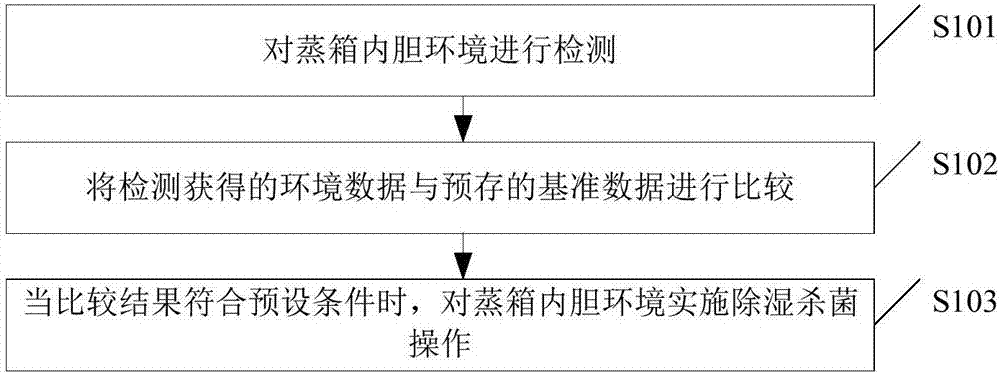

[0057] The embodiment of the present invention provides a control method for steam box dehumidification and sterilization, such as figure 1 As shown, the method includes S101-S102:

[0058] S101. Detect the environment of the inner tank of the steamer.

[0059] In the embodiment of the present invention, in order to determine whether mildew has occurred in the current environment of the inner tank of the steamer, or whether mildew may occur, the environmental data of the inner tank of the steamer can be detected in real time, so as to analyze the inner tank of the steamer according to the current environmental data. Judgments can be made based on the environmental conditions of the gall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com