A tank cleaning system and cleaning method

A cleaning system and tank technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems affecting the use of tanks, limited space on drilling platforms, small volume, etc., and achieve the goal of improving operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

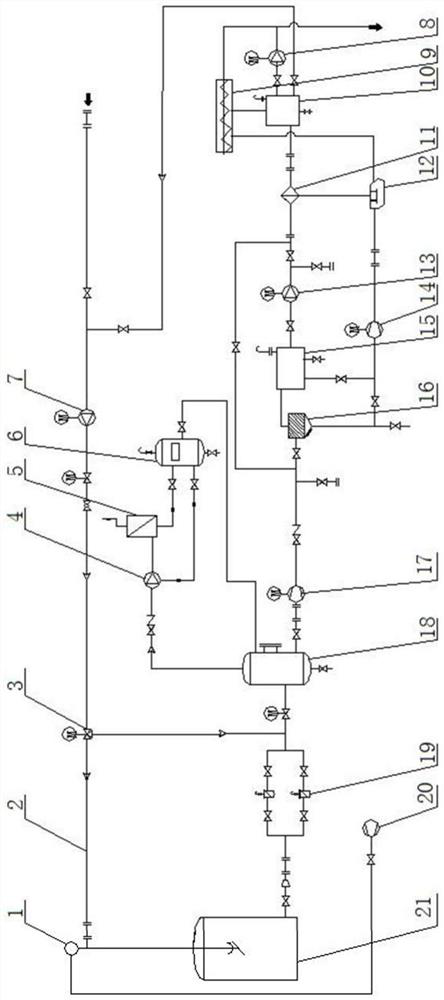

Image

Examples

Embodiment approach

[0021] In actual operation, the cleaning liquid may be oil-based or water-based. When water-based cleaning liquid is used, the oily substance contained in the water-based cleaning waste liquid needs to be removed during the recycling process. As an embodiment, the tank cleaning system further includes an oil-water separation device, the first liquid storage tank 10 is provided with a first liquid storage area and a second liquid storage area, and the first solid-liquid separation device 11 The drain port of the first liquid storage area is connected to the first liquid storage area and the second liquid storage area through the first pipeline and the second pipeline respectively, and the liquid discharge port of the first liquid storage area is connected to the cleaning liquid delivery pipe Road 2, the cleaning waste liquid in the second liquid storage area is returned to the first liquid storage area after oil-water separation by the oil-water separation device. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com