Wear-resistant down jacket cuff structure and manufacturing method thereof

A production method and technology for down jackets, applied in the field of down jackets, can solve the problems of unguaranteed wear resistance of fabrics, shortened service life of fabrics, and unsatisfactory use requirements, and achieve convenient cleaning and disassembly, improve adhesion, and ensure warmth retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

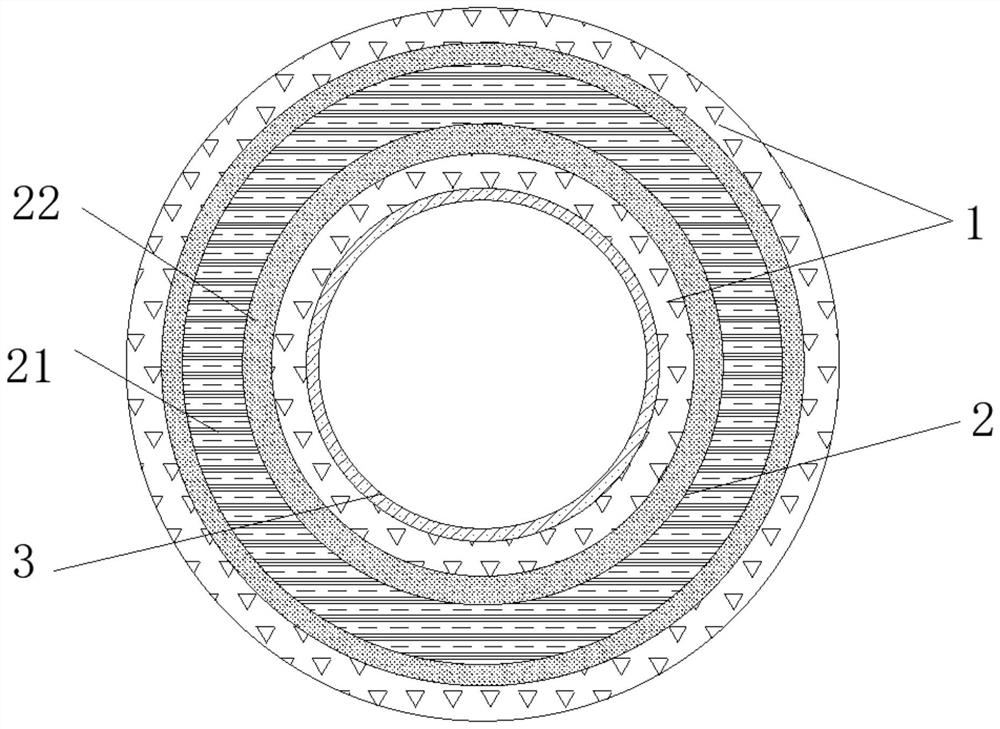

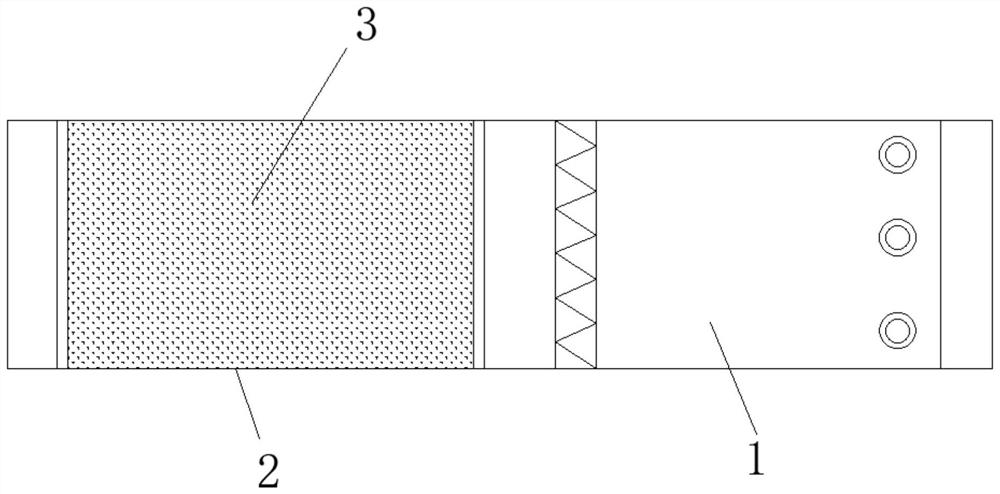

[0035] A wear-resistant down jacket cuff structure, including a hollow cuff body 2 connected to the sleeve, and a fabric protection layer 1 located on the surface of the cuff body 2 to prevent the cuff body 2 from entering the wind and frequent cleaning. Warm layer 3 on the inner side of layer 1 for warming the wrist;

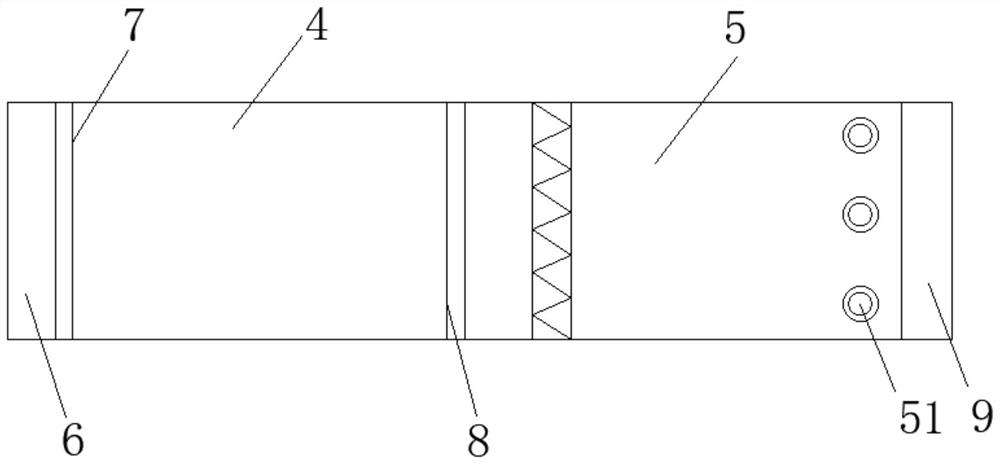

[0036] Wherein, the fabric protection layer 1 comprises the inner protective layer 4 positioned at the inner side of the cuff body 2, the No. 1 folded portion 7 positioned at one side of the inner protective layer 4, the second folded portion 8 positioned at the other side end of the inner protective layer 4, The No. 1 turning part 7 is facing away from the No. 1 connecting part 6 on the side of the inner sheath 4, the outer sheath 5 on the side of the No. The No. 2 connecting portion 9 on the side of the No. 1 folded portion 8 and the tightening band 52 located on the side of the outer sheath 5 facing the No. 2 folded portion 8 and located outside the cuff bod...

Embodiment 2

[0045] A wear-resistant down jacket cuff structure, including a hollow cuff body 2 connected to the sleeve, and a fabric protection layer 1 located on the surface of the cuff body 2 to prevent the cuff body 2 from entering the wind and frequent cleaning. Warm layer 3 on the inner side of layer 1 for warming the wrist;

[0046] Wherein, the fabric protection layer 1 comprises the inner protective layer 4 positioned at the inner side of the cuff body 2, the No. 1 folded portion 7 positioned at one side of the inner protective layer 4, the second folded portion 8 positioned at the other side end of the inner protective layer 4, The No. 1 turning part 7 is facing away from the No. 1 connecting part 6 on the side of the inner sheath 4, the outer sheath 5 on the side of the No. The No. 2 connecting portion 9 on the side of the No. 1 folded portion 8 and the tightening band 52 located on the side of the outer sheath 5 facing the No. 2 folded portion 8 and located outside the cuff bod...

Embodiment 3

[0055] A wear-resistant down jacket cuff structure, including a hollow cuff body 2 connected to the sleeve, and a fabric protection layer 1 located on the surface of the cuff body 2 to prevent the cuff body 2 from entering the wind and frequent cleaning. Warm layer 3 on the inner side of layer 1 for warming the wrist;

[0056] Wherein, the fabric protection layer 1 comprises the inner protective layer 4 positioned at the inner side of the cuff body 2, the No. 1 folded portion 7 positioned at one side of the inner protective layer 4, the second folded portion 8 positioned at the other side end of the inner protective layer 4, The No. 1 turning part 7 is facing away from the No. 1 connecting part 6 on the side of the inner sheath 4, the outer sheath 5 on the side of the No. The No. 2 connecting portion 9 on the side of the No. 1 folded portion 8 and the tightening band 52 located on the side of the outer sheath 5 facing the No. 2 folded portion 8 and located outside the cuff bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com