Inner cover of one-way exhaust decompression plastic bottle

A one-way exhaust, plastic bottle technology, applied in the field of plastic bottle inner caps, can solve the problems of increased air pressure and inability to release, and achieves the effect of ensuring food hygiene, low manufacturing cost, and preventing internal pressure increase and bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

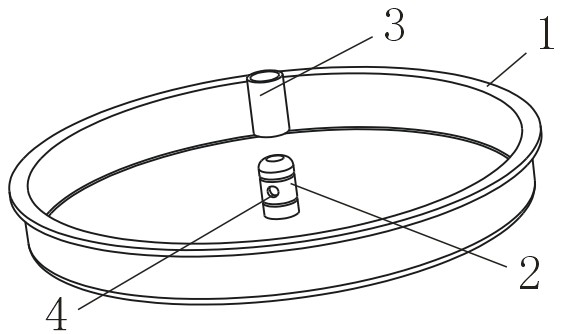

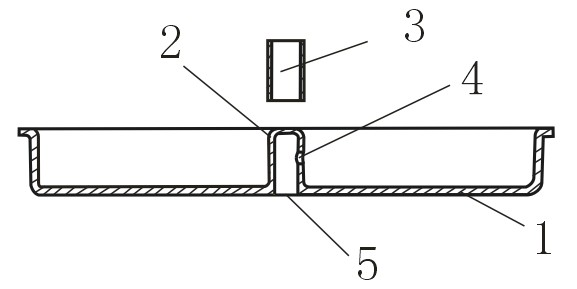

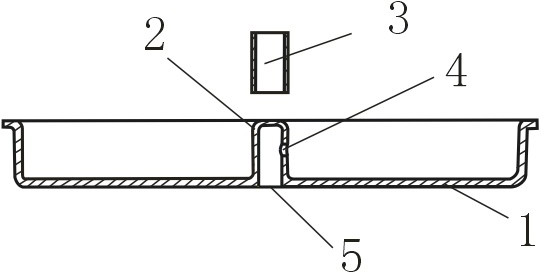

[0014] One-way exhaust decompression plastic bottle inner cover is characterized in that a one-way exhaust device is set in the middle of the inner cover 1, and the one-way exhaust device is provided with an exhaust pipe 2 in the middle of the inner cover 1, and the exhaust pipe 2. The shape on the inner cover is an exhaust pile, and the exhaust pipe 2 is integrally formed with the inner cover 1. The elastic seal 3 is a soft rubber hose, the exhaust pile is socketed with the soft rubber hose, and the upper mouth 4 of the exhaust pipe 2 is sealed by the soft rubber hose, and the lower mouth 5 of the exhaust pipe is connected to the lower chamber of the plastic bottle. When the air pressure in the bottle rose, the high-pressure gas broke through the pressure of the soft rubber hose through the exhaust pipe 2 and flowed to the top of the bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com