Flotation machine impeller for increasing width of conveying area

A flotation machine and width technology, applied in flotation, solid separation, etc., can solve problems such as inability to produce air dispersion and pulp circulation, poor recovery effect of flotation machines, and reduced probability of secondary collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below. The content not described in detail in the embodiments of the present invention belongs to the prior art known to those skilled in the art.

[0017] The flotation machine impeller with wider transport area width of the present invention, its preferred embodiment is:

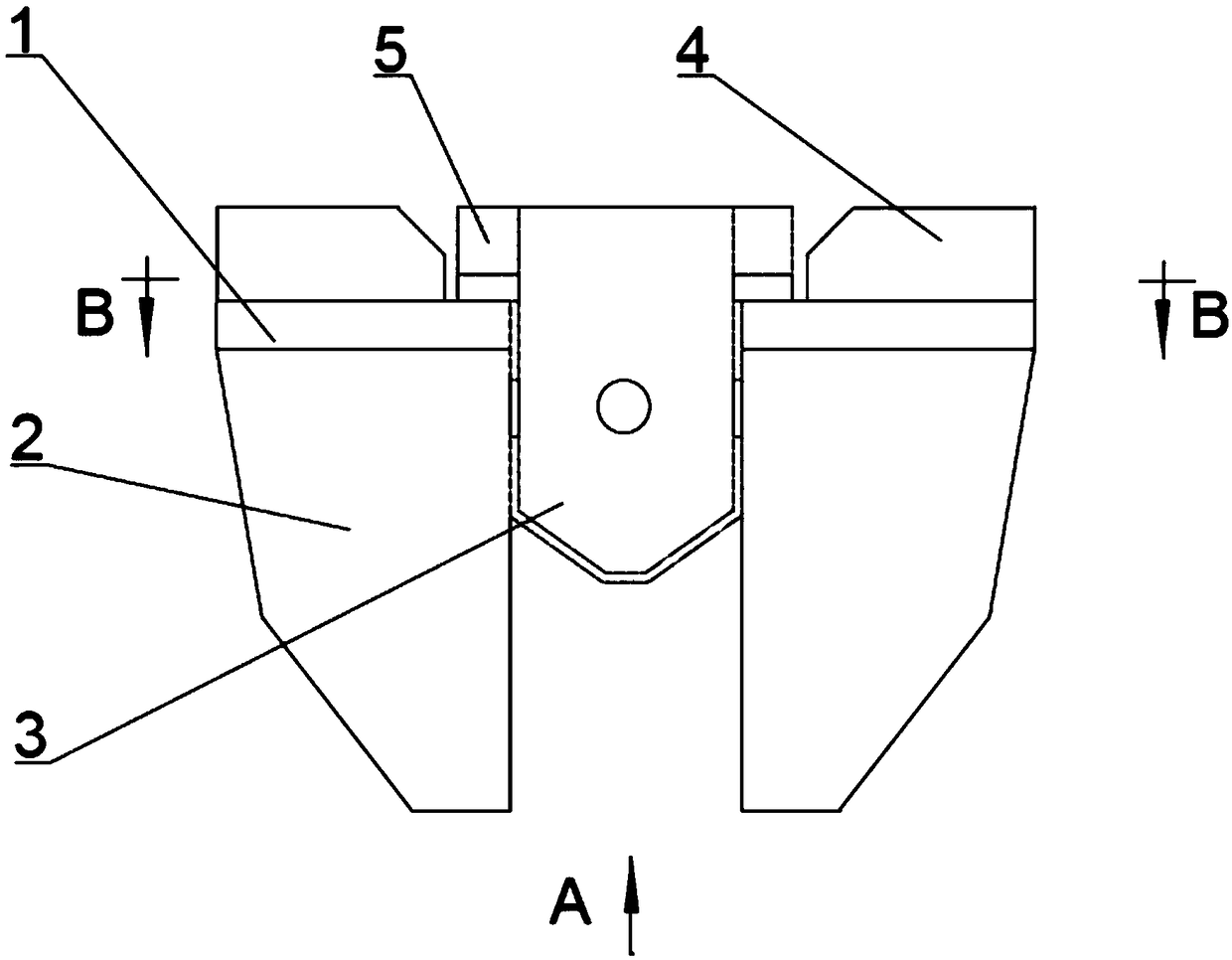

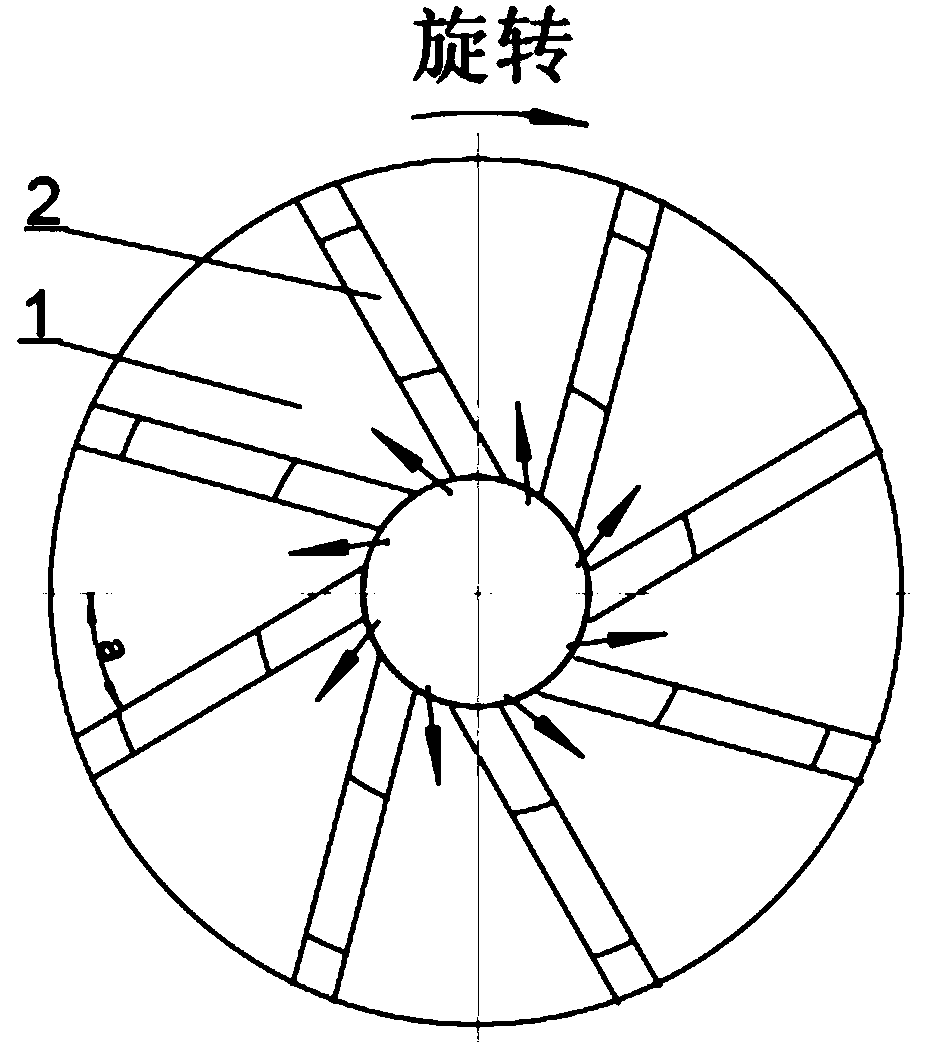

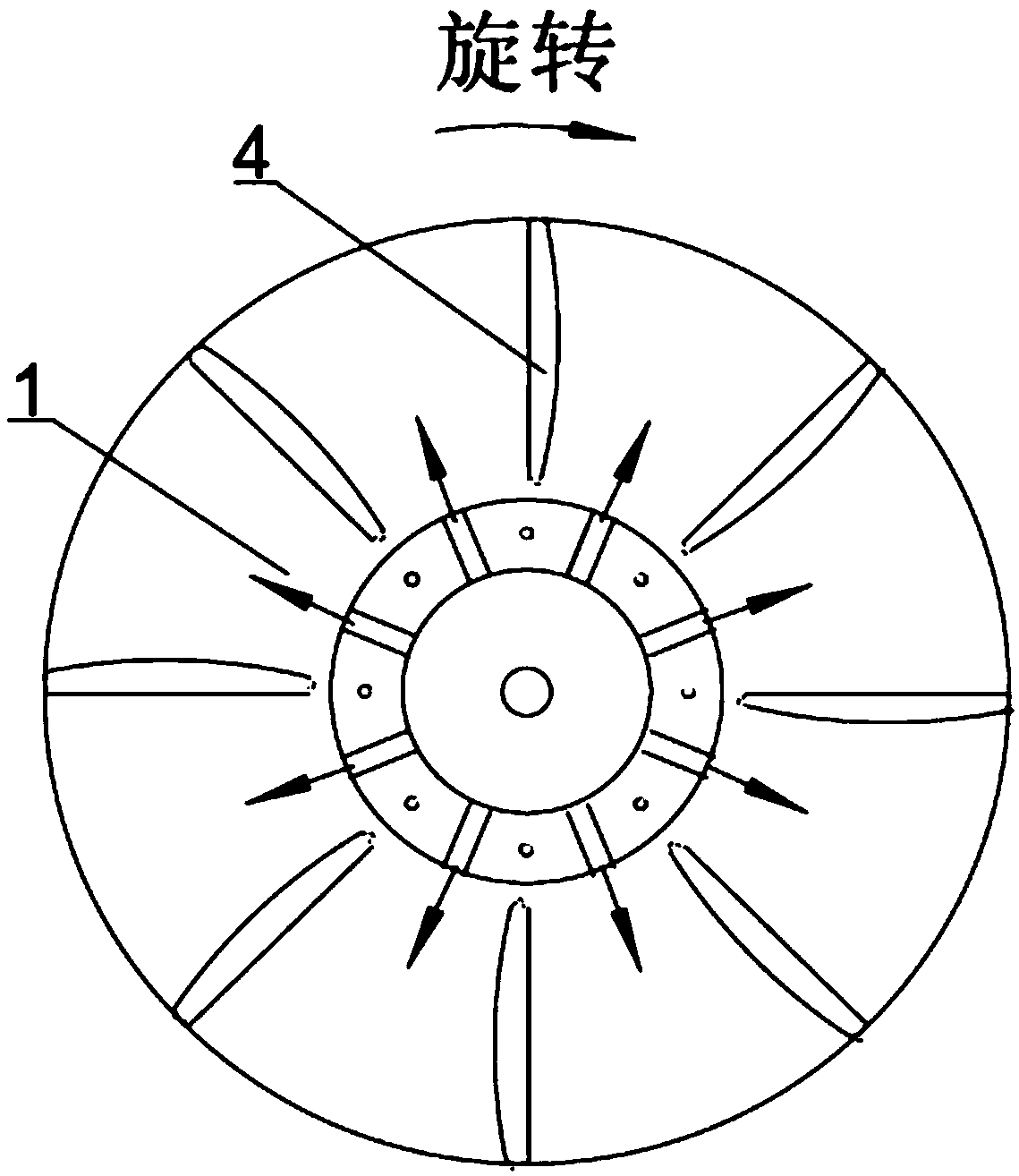

[0018] It includes a circular cover plate, the upper part of the circular cover plate is provided with an upper blade and an upper air dispersing device, the lower part of the circular cover plate is provided with a lower blade and a lower air dispersing device, and the middle of the circular cover plate An inner air passage hole is provided, and the inner passage of the lower air dispersion device communicates with the inner passage of the upper air dispersion device through the inner air passage hole.

[0019] The inner side of the lower blade is straight, the outer edge is double hypotenuse, the bottom is narrow and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com