Fixing frame for automobile brake disc processing

A technology for automobile brakes and fixing frames, which is applied to metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of inability to move and inconvenient to use, and achieve the effect of convenient processing and firm fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

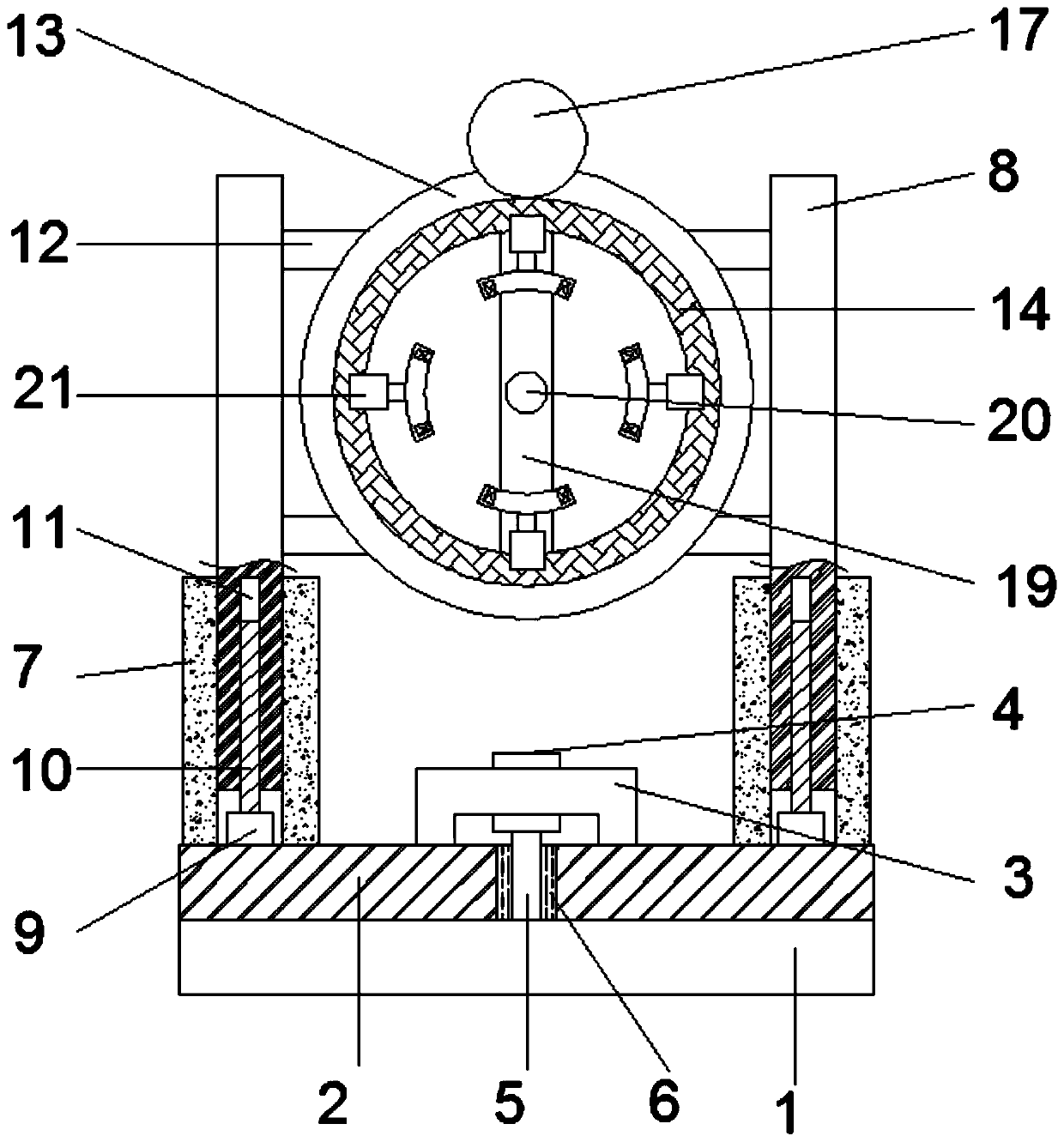

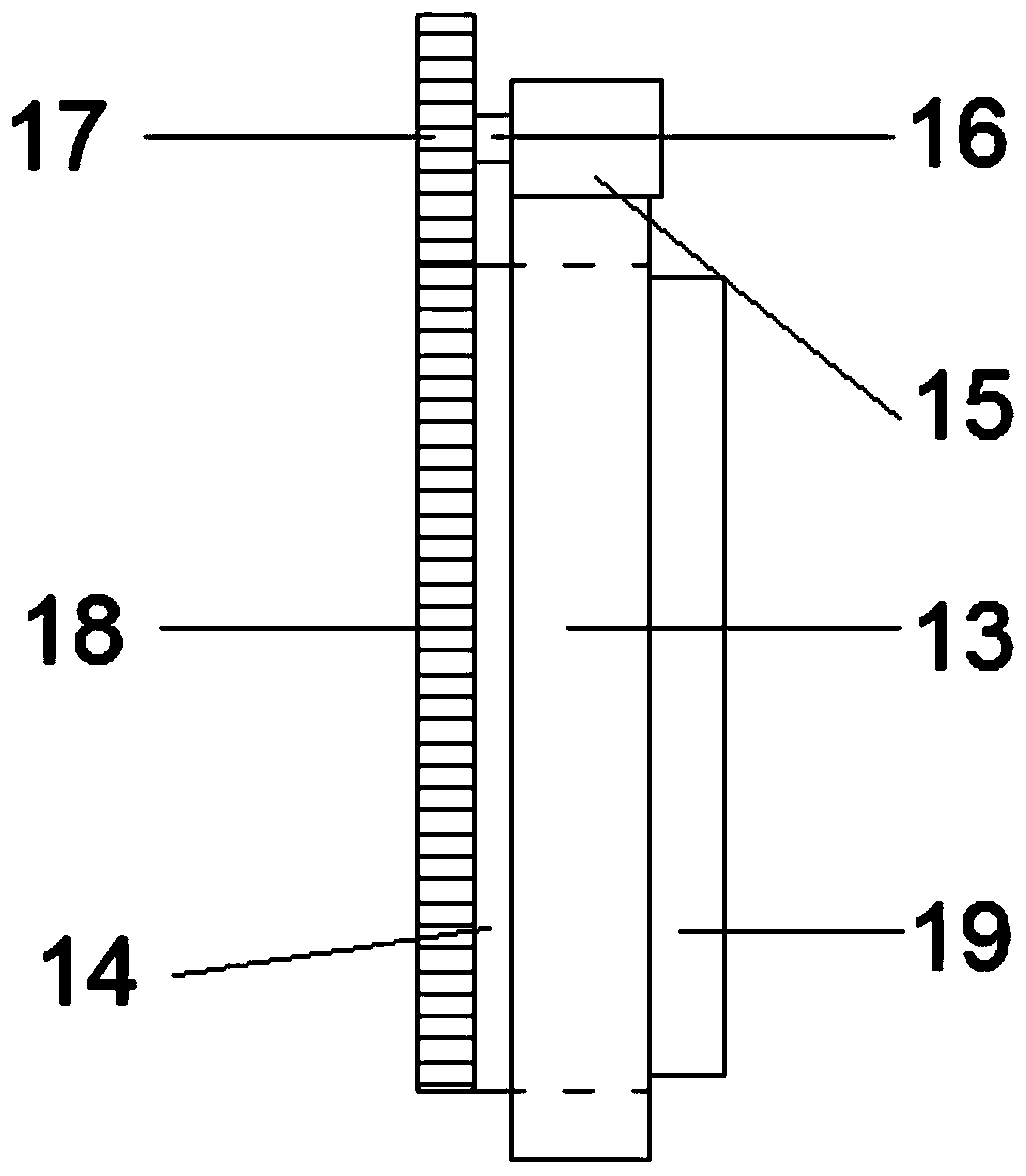

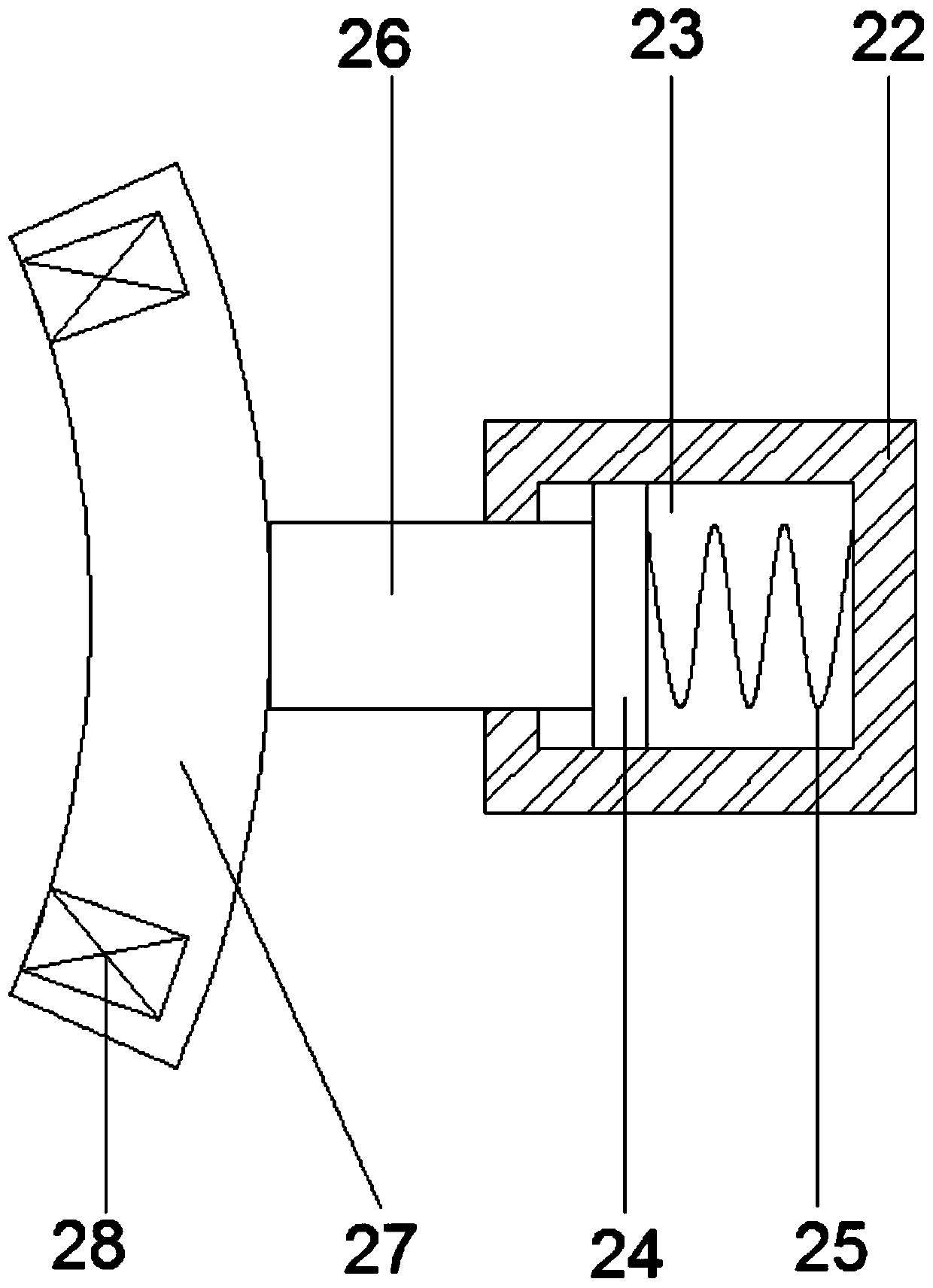

[0019] Such as Figure 1-Figure 3 As shown, the present invention proposes a fixed frame for processing an automobile brake disc, comprising a fixed base 1, a first motor 4, a screw mandrel 10, a gear tooth structure 18 and a fixed assembly 21, and the upper end of the fixed base 1 is provided with a rotating base 2, And the middle part of the upper end of the rotating base 2 is provided with a first motor 4, the middle part of the lower end of the first motor 4 is connected to the first rotating shaft 5, the lower end of the first rotating shaft 5 runs through the rotating base 2, and the lower end of the first rotating shaft 5 is connected to the fixed base 1, and the upper end of the rotating base 2 is left and right Both sides are symmetrically provided with fixed pipe 7, and the inner side of fixed pipe 7 is slidingly connected with the lower part of lifting rod 8, the inner bottom of fixed pipe 7 is provided with second motor 9, and the middle part of the upper end of sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com