Ventilated and cooled fairing structure

A ventilation cooling and fairing technology, which is applied in the direction of rotorcraft, aircraft parts, aircraft, etc., can solve the problems of consuming a lot of design time and cost, design cost and post-manufacturing cost, and the ventilation volume of the rear power cabin cannot be guaranteed. Effect of improving ventilation and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

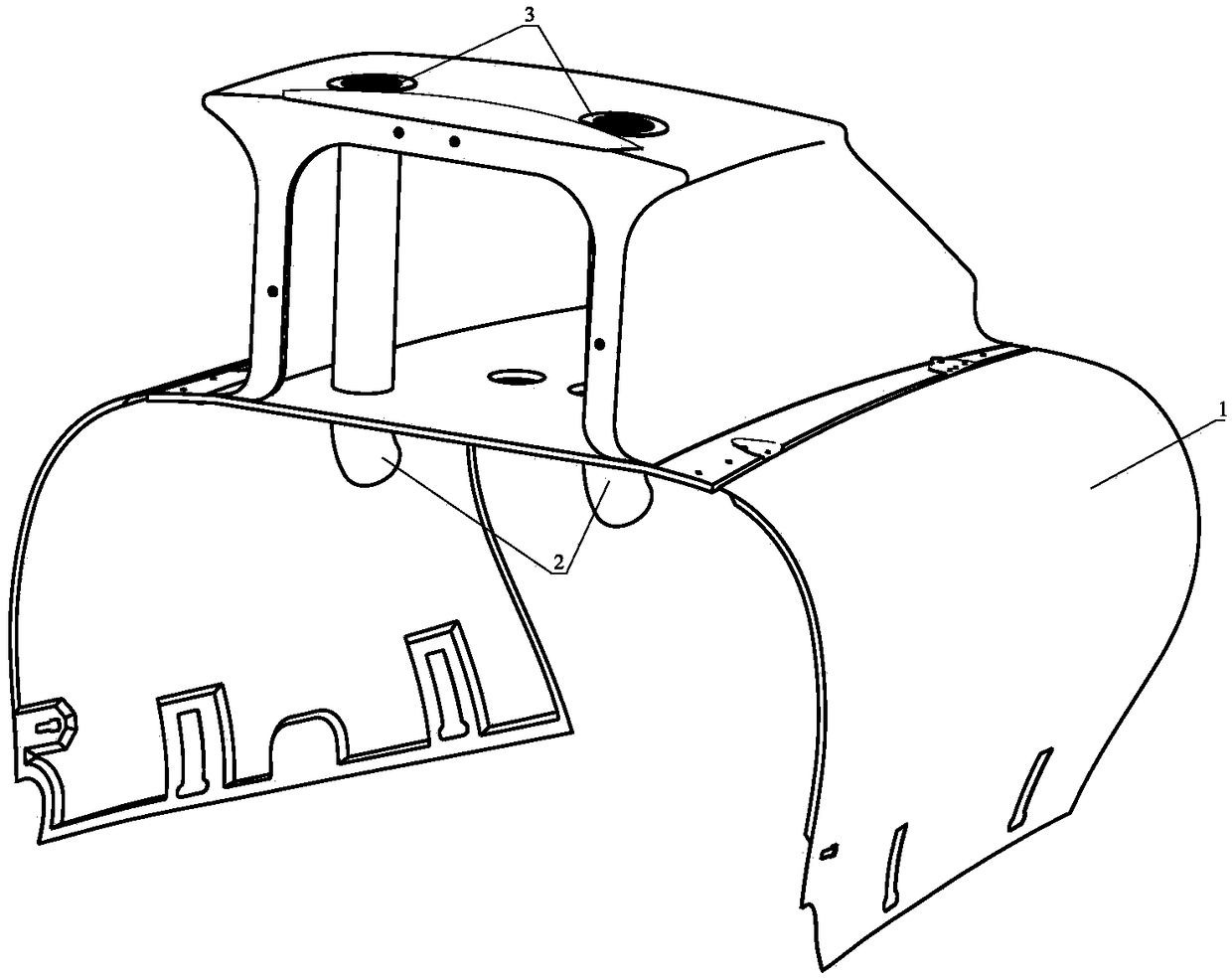

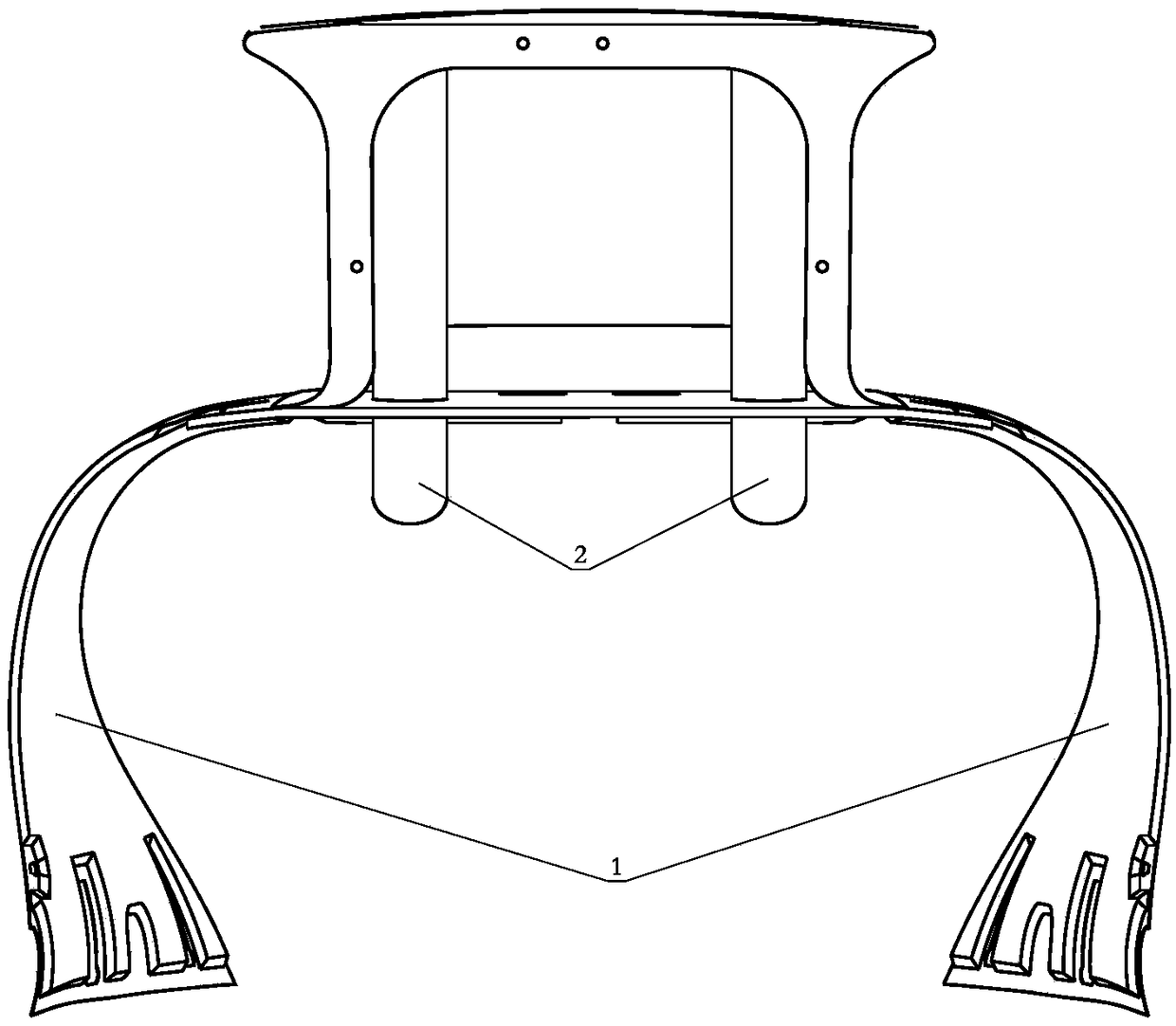

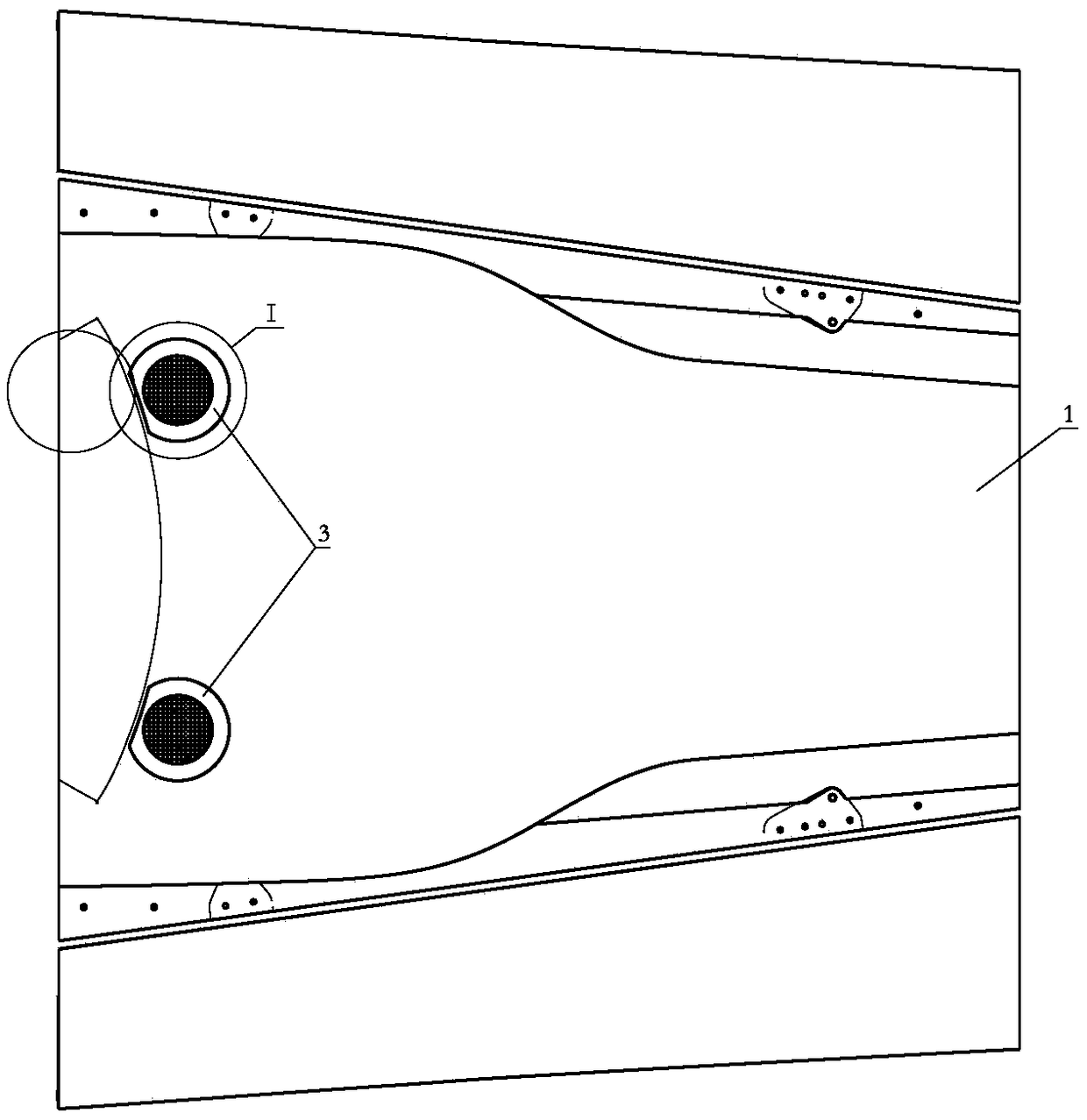

[0020] The present invention comprises fairing 1, ventilation intake pipe 2, air intake grid 3 and circular backing plate 4 such as Figure 1-5 As shown, the fairing 1 is an engine compartment fairing, which provides installation space for a high-power engine such as figure 1 As shown; the ventilation intake pipe 2 is installed in the channel opening of the upper fixed cover of the fairing 1 and the upper partition, and the axial distance of the ventilation intake pipe 2 on the left and right sides is 410mm, and the symmetrical arrangement is as follows: figure 2 As shown, the air inlet pipe is 143mm away from the front plane of the fairing. image 3 As shown, the ventilation inlet pipe 2 is a long cylindrical gas channel such as figure 1 , figure 2 As shown, the section radius is R83mm, and the length is about 600mm. This structure controls the intake direction and flow v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com