Method for automatically taking out car tweeter and carrying out hole separation by using device

A technology for tweeters and automobiles, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as low production efficiency, time-consuming, and product mixing, and achieve the goals of preventing injuries, improving operating efficiency, and saving time for point separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

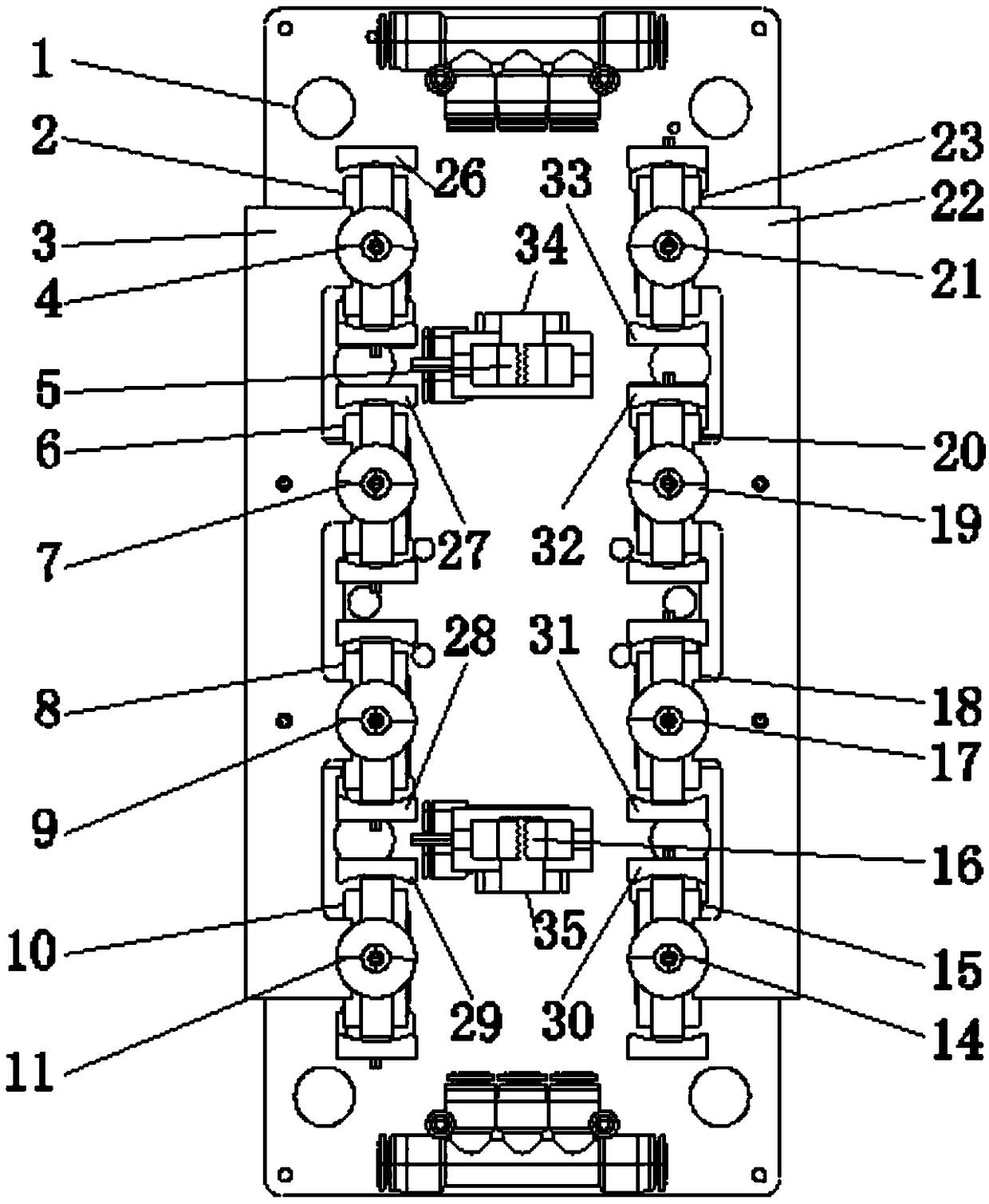

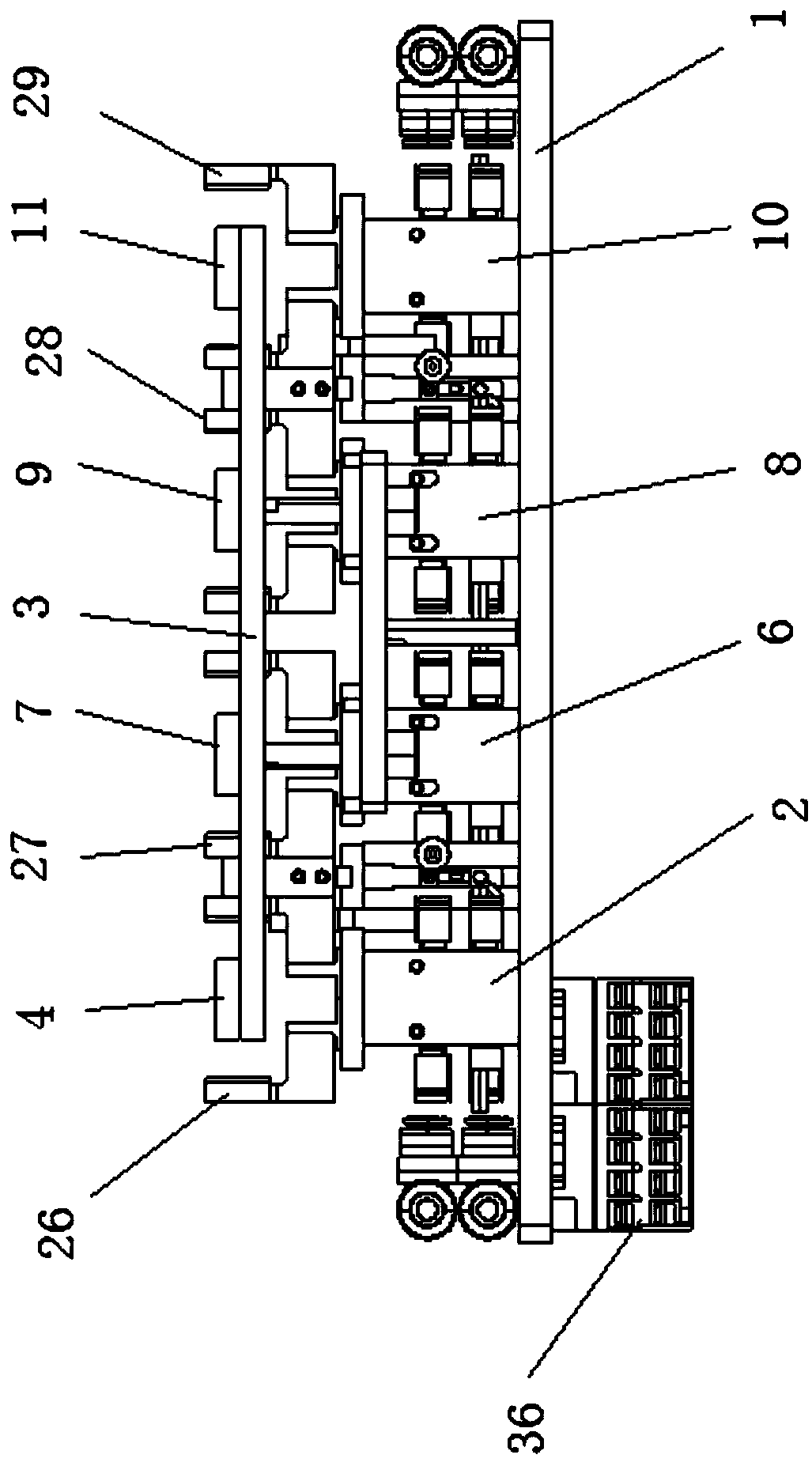

[0022] Such as figure 1 , 2 As shown, a device for automatically taking out a car tweeter produced by multiple cavities and dividing the cavities includes a base plate 1, an L-side linkage plate 3, an R-side linkage plate 22, a clamping product mechanism, a clamping handle mechanism, and a signal transmission mechanism. Sensing system and control system, the L-side linkage plate 3 and the R-side linkage plate 22 are respectively installed on both sides of the base plate 1 through springs, and the clamping product mechanism and the clamping material handle mechanism are installed on the base plate 1, and the control The system is connected with the clamping product mechanism and the clamping material handle mechanism through the signal sensing system.

[0023] Among them, there are four product positioning cores on the L-side linkage plate 3, which are respectively positioning core 1 4, positioning core 2 7, positioning core 3 9, positioning core 4 11, and R-side linkage plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com