An accurate tension control method and device for a high-speed binding machine

A technology of tension control and binding machine, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials. It can solve the problems of optical fiber force attenuation and instability, and achieve high binding speed, weight reduction, and The effect of tension stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

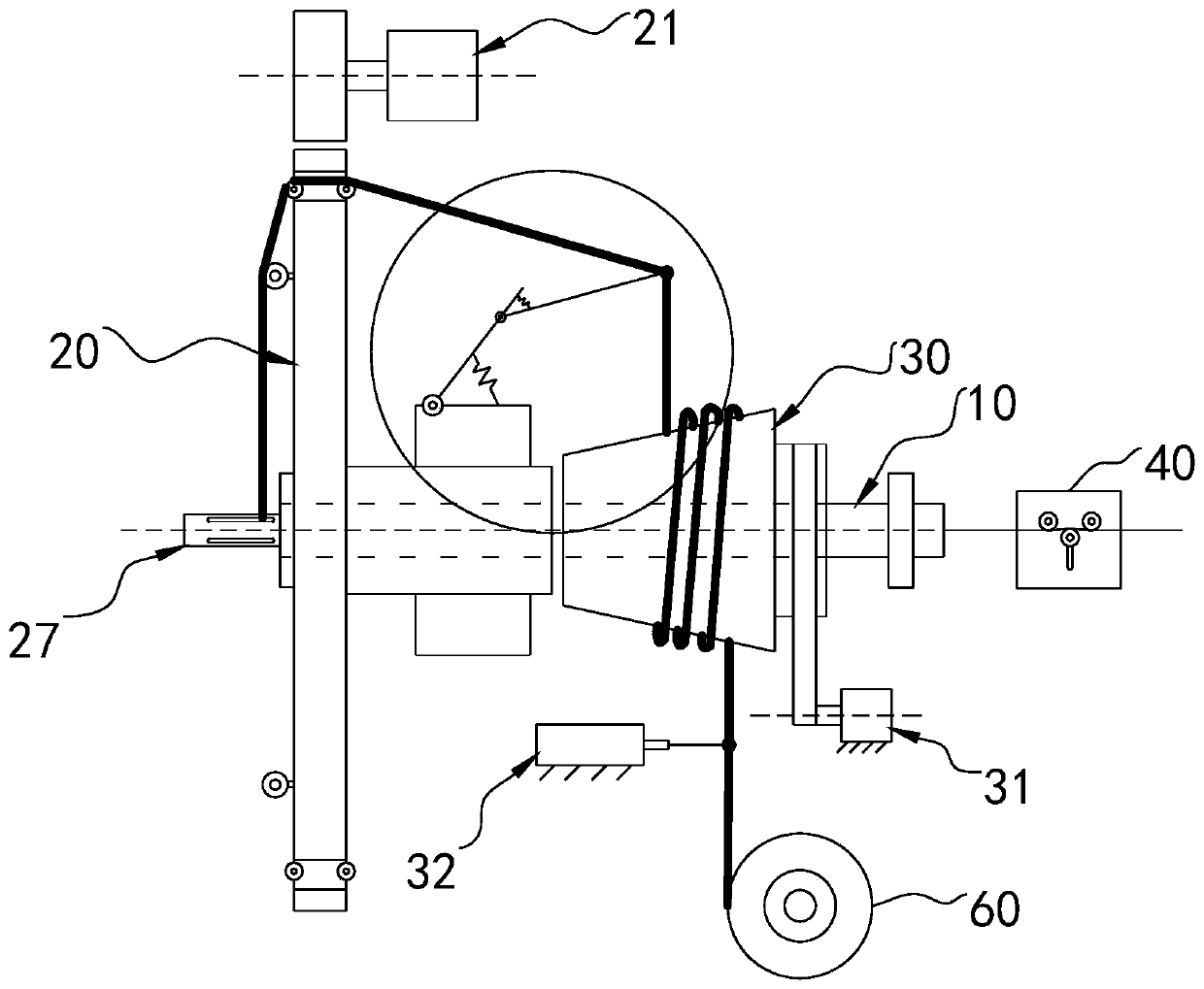

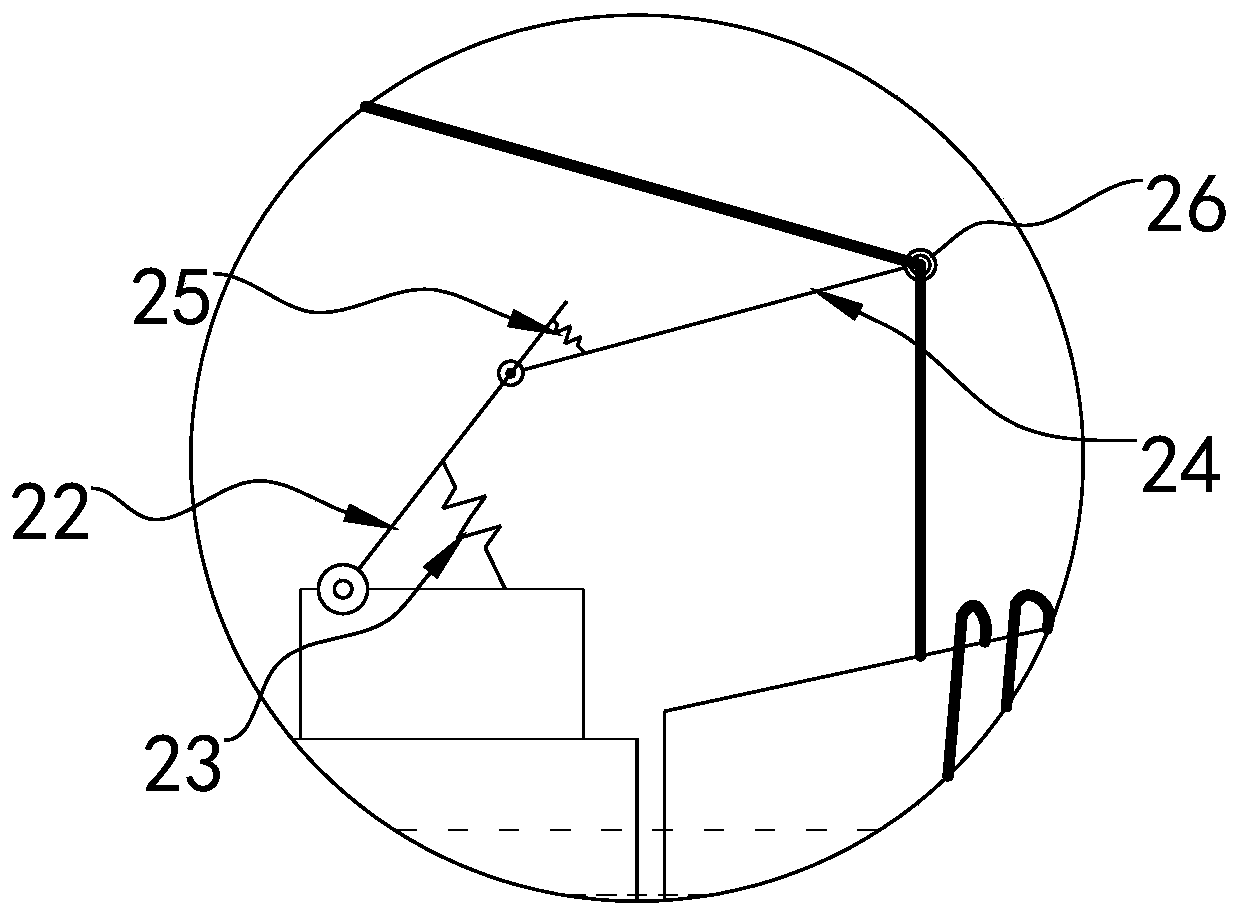

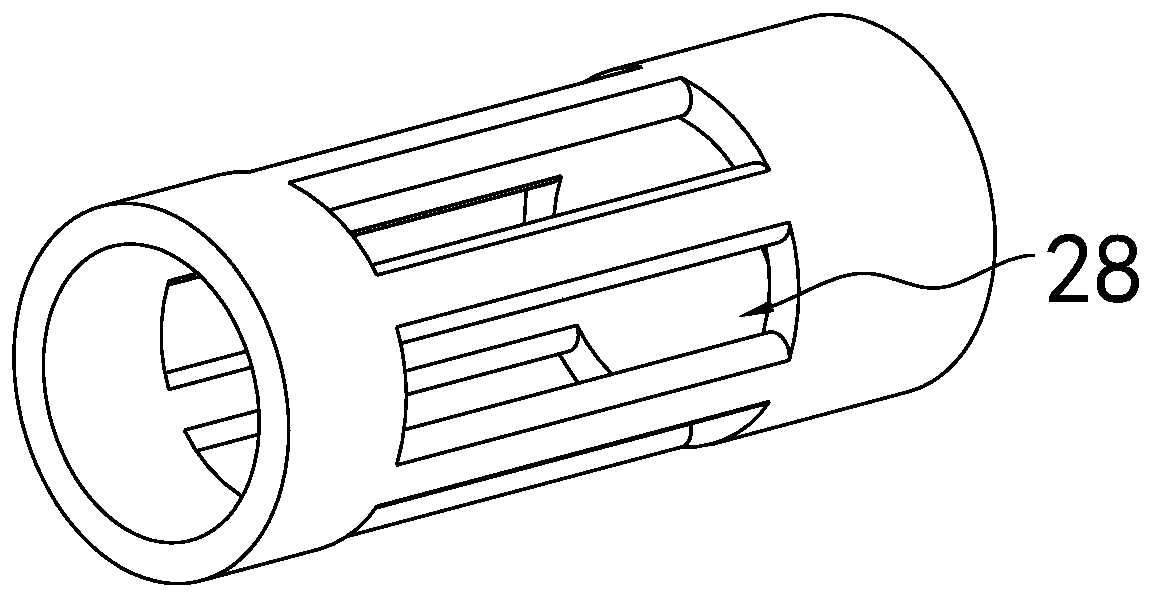

[0027] Embodiment: a precise tension control method of high-speed yarn binding machine, comprising the following steps:

[0028] a. Install a full coil of yarn on the high-speed yarn binding machine;

[0029] b. Set the start-up speed of the take-up reel to 35-45m / min;

[0030] c. Turn on the yarn binding machine, set the yarn binding speed to 100m / min, then reduce the yarn binding speed, and measure the yarn binding tension once every 10m / min drop;

[0031] d. Adjust the tension setting of the yarn binding, so that the yarn binding tension in step c is 2-4N;

[0032] e. Increase the yarn binding speed from 10m / min to 100m / min, and then reduce it from 100m / min to 10m / min, and continuously measure the yarn binding tension in this process;

[0033] f. Adjust the yarn up and down speed compensation to correct full yarn and shallow yarn properties, so that the yarn binding tension in step e is 2-6N;

[0034] g. Install the shallow disc yarn on the high-speed yarn binding machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com