Weather-resistant lamp, and manufacturing method of light emitting module of weather-resistant lamp

A light-emitting module and weather-resistant technology, which is applied to semiconductor devices of light-emitting elements, light sources, lampshades, etc., can solve problems such as light-emitting module failures and easy cracking of the cover plate, and achieve the effect of not being easily cracked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

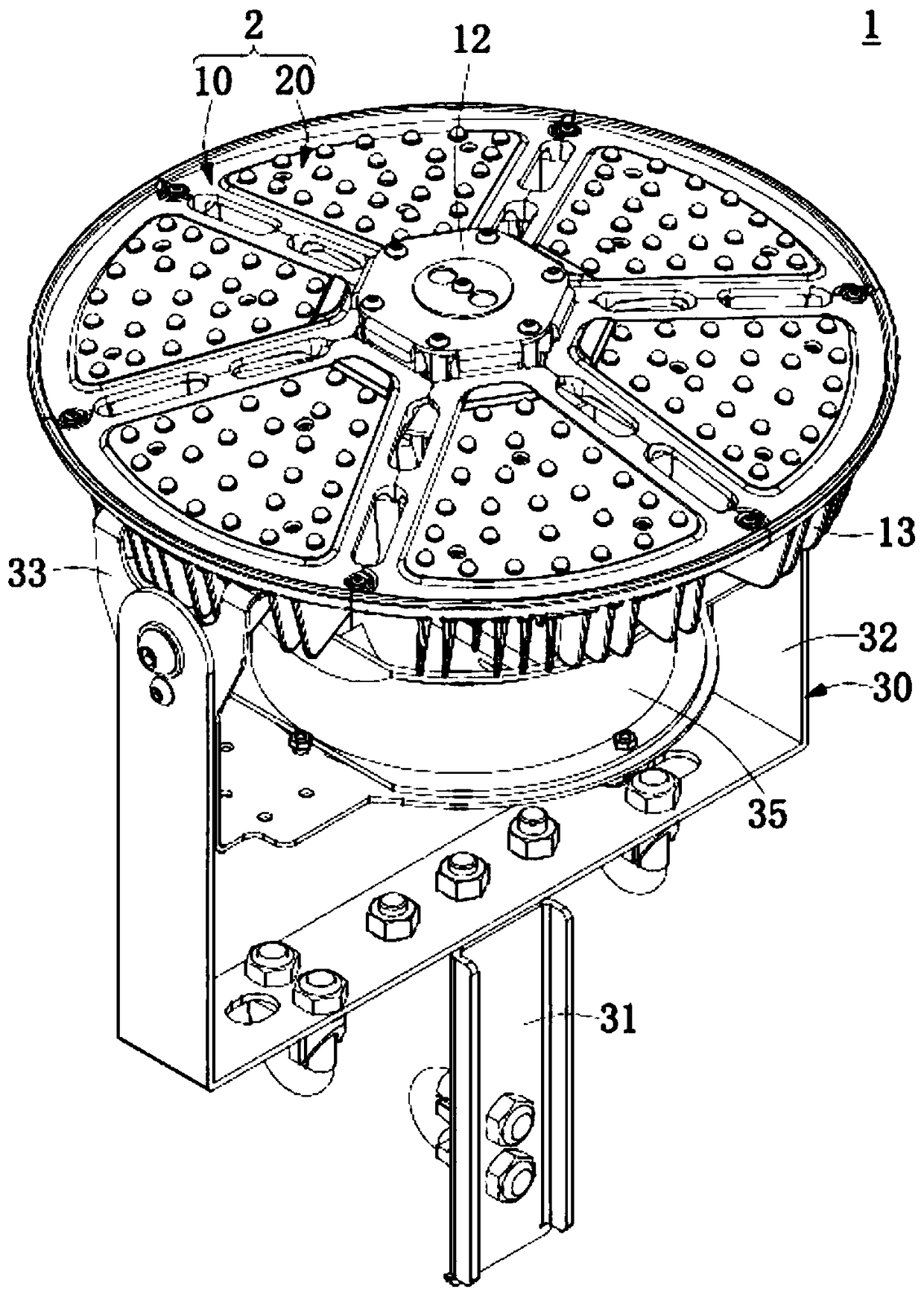

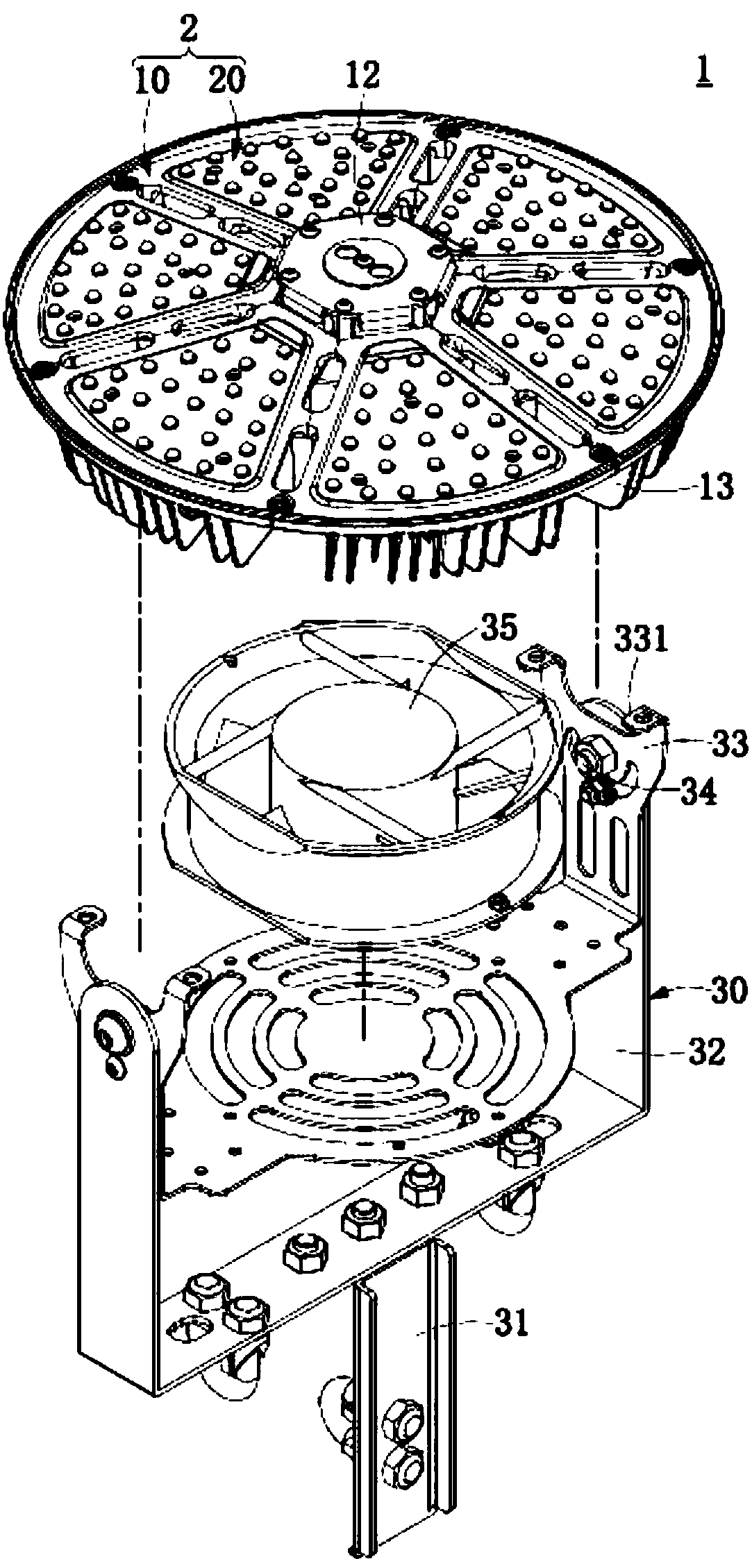

[0028] The invention provides a weather-resistant lamp, in particular a weather-resistant lamp suitable for fishing boats. Such as Figure 1 to Figure 6 As shown, the weather-resistant lamp 1 of the present invention mainly includes a plurality of light emitting modules 20 , a plurality of heat dissipation bases 10 , and a bracket module 30 .

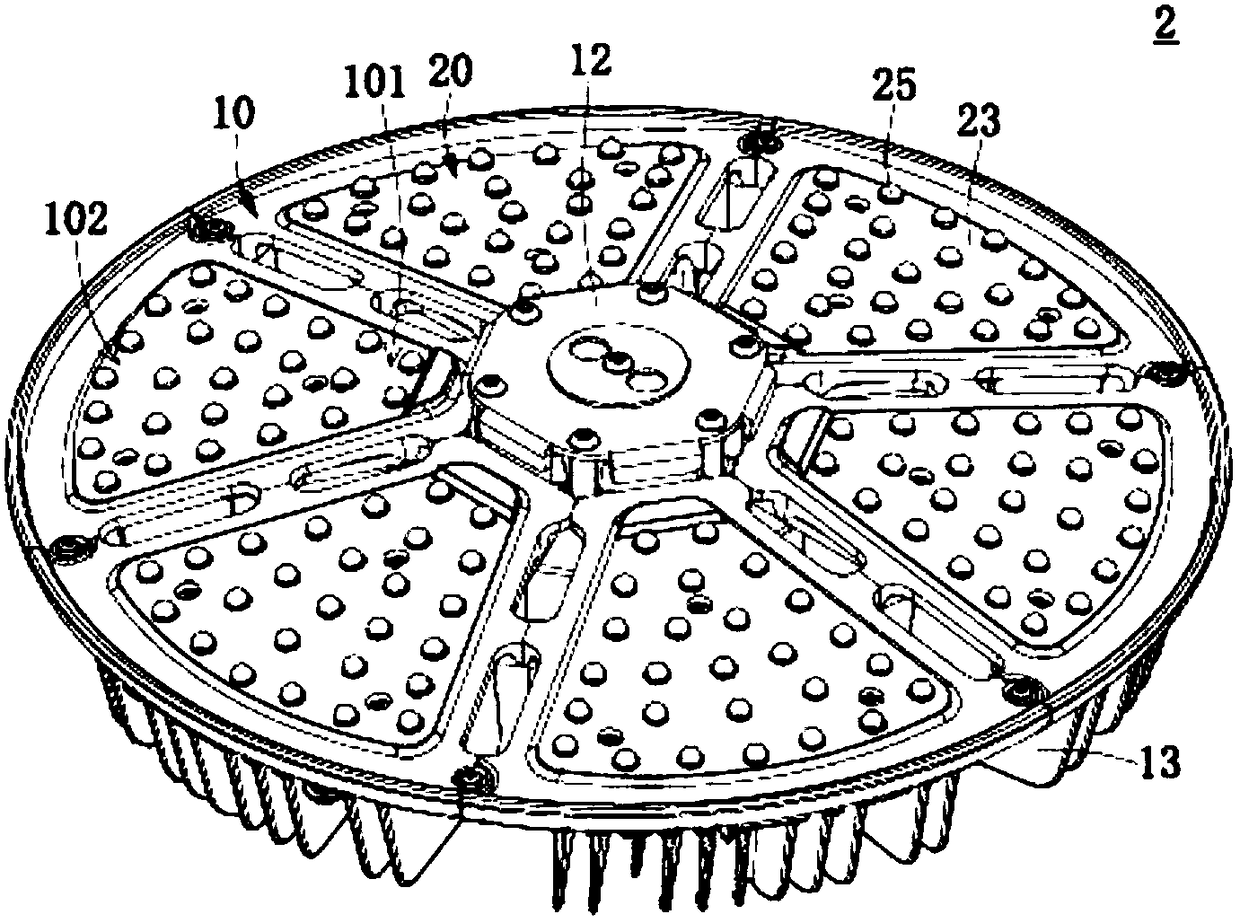

[0029] Such as image 3 and Figure 4 As shown, each heat dissipation base 10 is substantially wedge-shaped, and the two ends of each heat dissipation base 10 respectively have a first end 101 and a second end 102, wherein the width of the first end 101 is smaller than that of the second end 102 width, and the first end 101 can be connected to the outside of a base 12 . And each heat dissipation base 10 is respectively provided with a first connecting portion 103 and a second connecting portion 104 on two sides of the second end 102 . Such as image 3 As shown, when the first end 101 of each heat dissipation base 10 is jointly conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap