Burner installation for increased safety

A burner and safety technology, applied in the field of burner devices to improve safety, can solve the problems of dangerous flashing, prolonging burning time, maintaining fuel temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

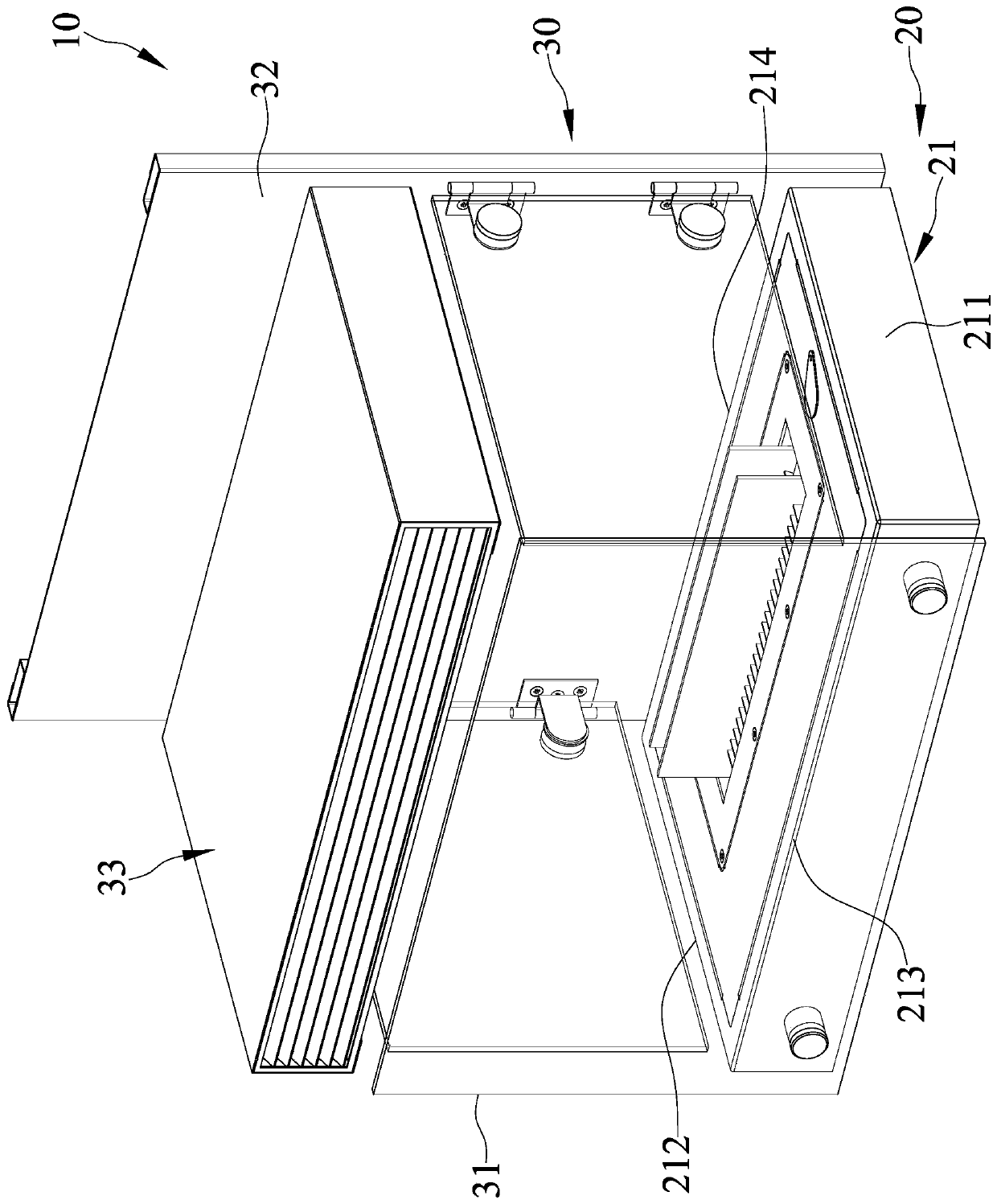

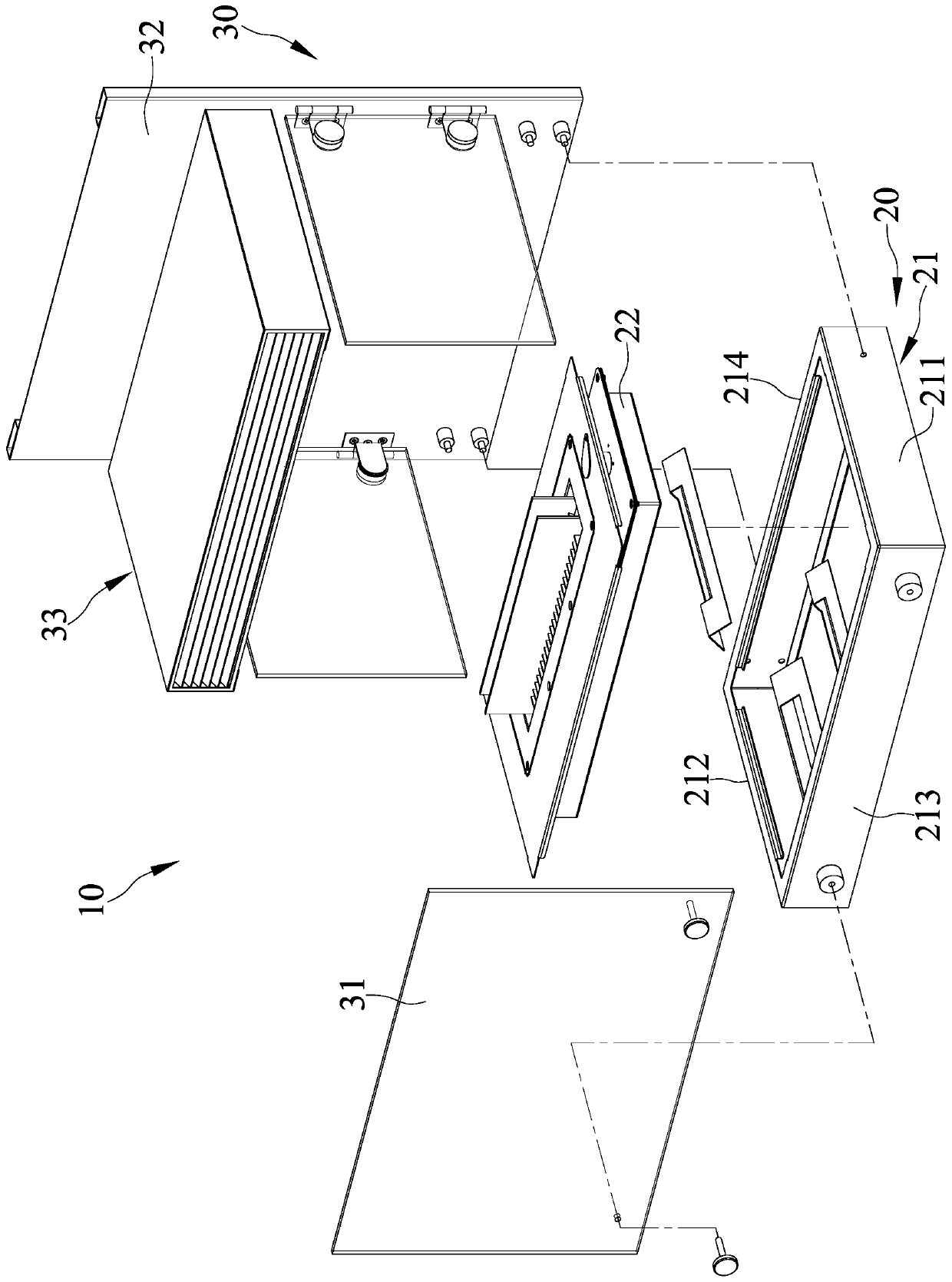

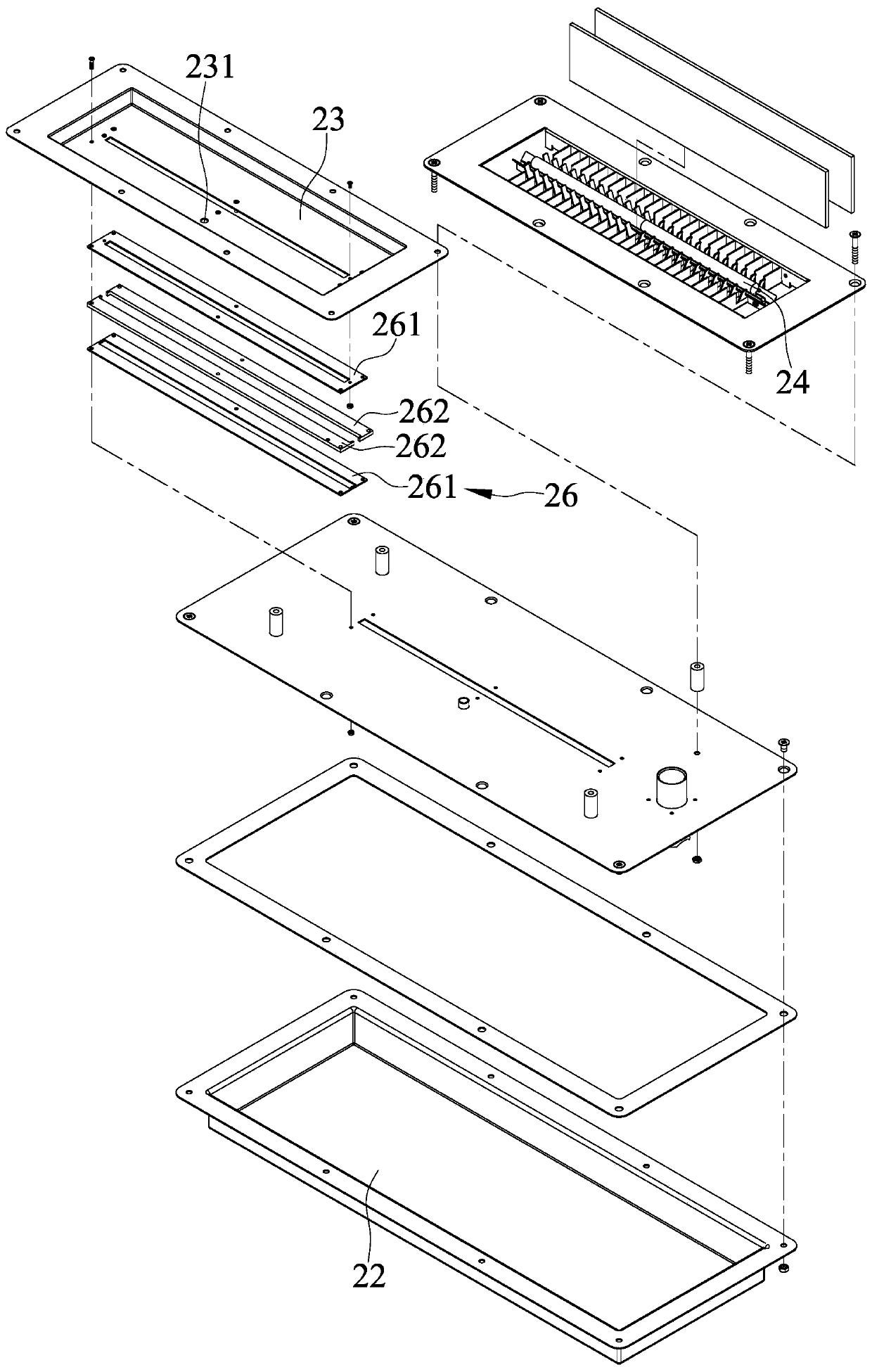

[0020] Please refer to Figure 1 to Figure 5 Shown is the three-dimensional appearance view, three-dimensional exploded view and cross-sectional structure view of the safety-improving burner device of the present invention. The burner device 10 of the present invention includes a furnace body 20 and a diversion module 30; wherein:

[0021] The furnace body 20 includes a shell 21, a fuel tank 22, a fuel tray 23 and a candle wick 24. The shell 21 includes a first end 211 and a second end 212. The first end 211 of the shell 21 The second end 212 is the two different ends of the housing 21 along the horizontal direction, the housing 21 includes a first side 213 and a second side 214, the first side 213 and the second side 214 are the housing 21 on different sides along the other horizontal direction. The fuel tank 22 is disposed in the casing 21, the fuel tray 23 is connected to the top side of the casing 21, the fuel tray 23 is located above the fuel tank 22 along the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com