A method based on visual precise positioning of incoming materials to the test box

A technology of precise positioning and testing boxes, which is applied in the direction of measuring devices, program-controlled manipulators, instruments, etc., and can solve problems such as errors, large offsets of incoming materials, and poor alignment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

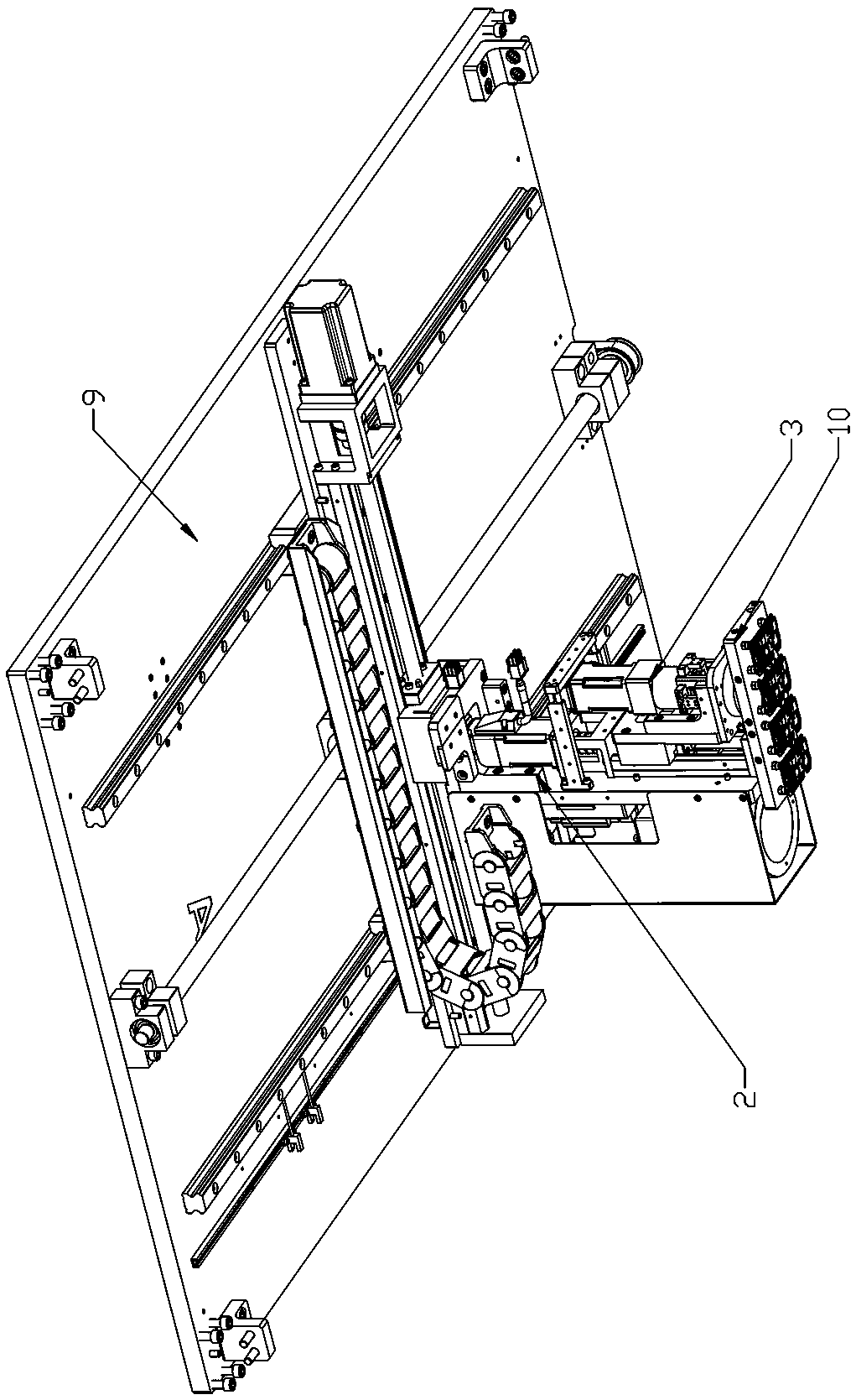

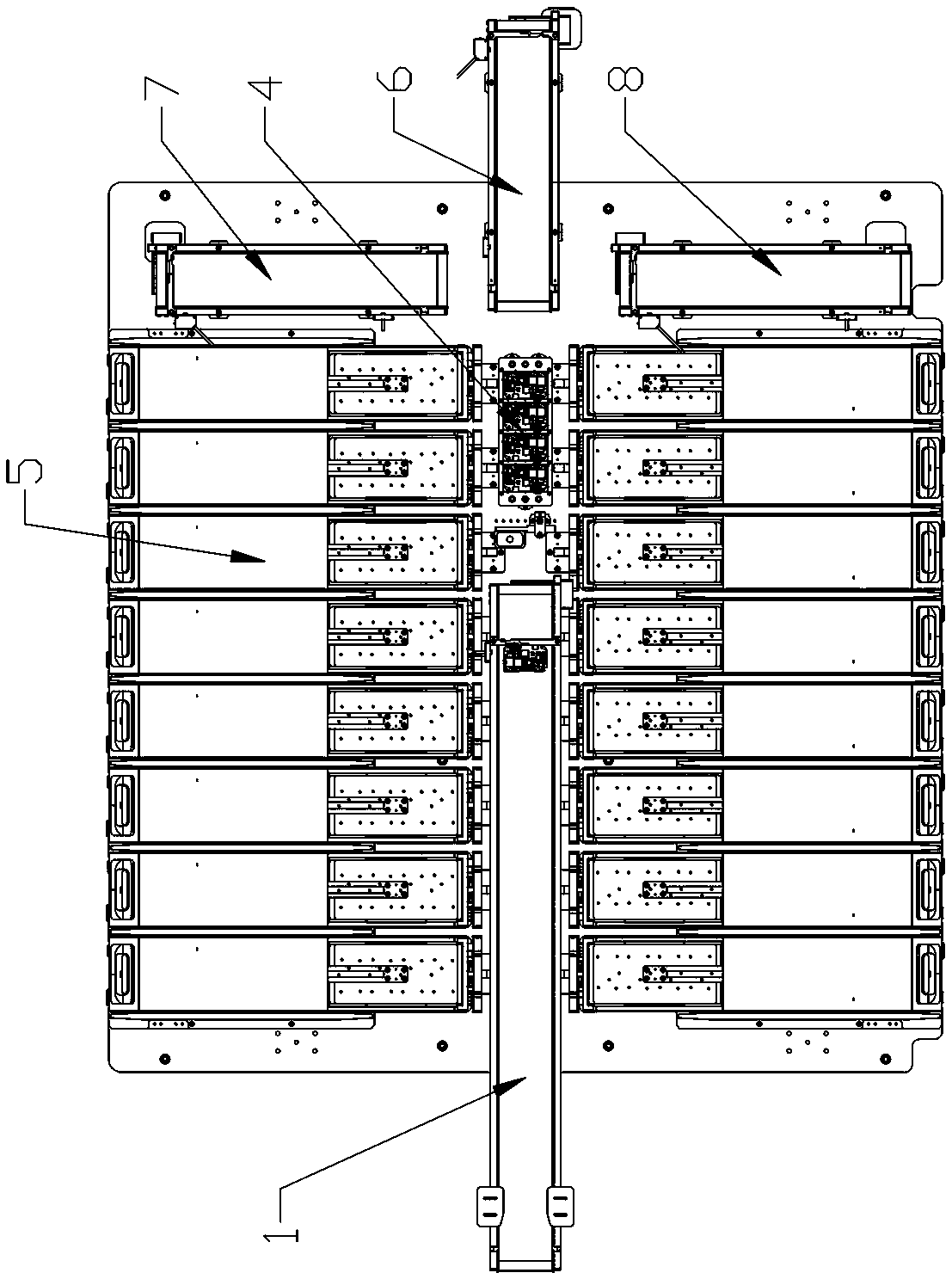

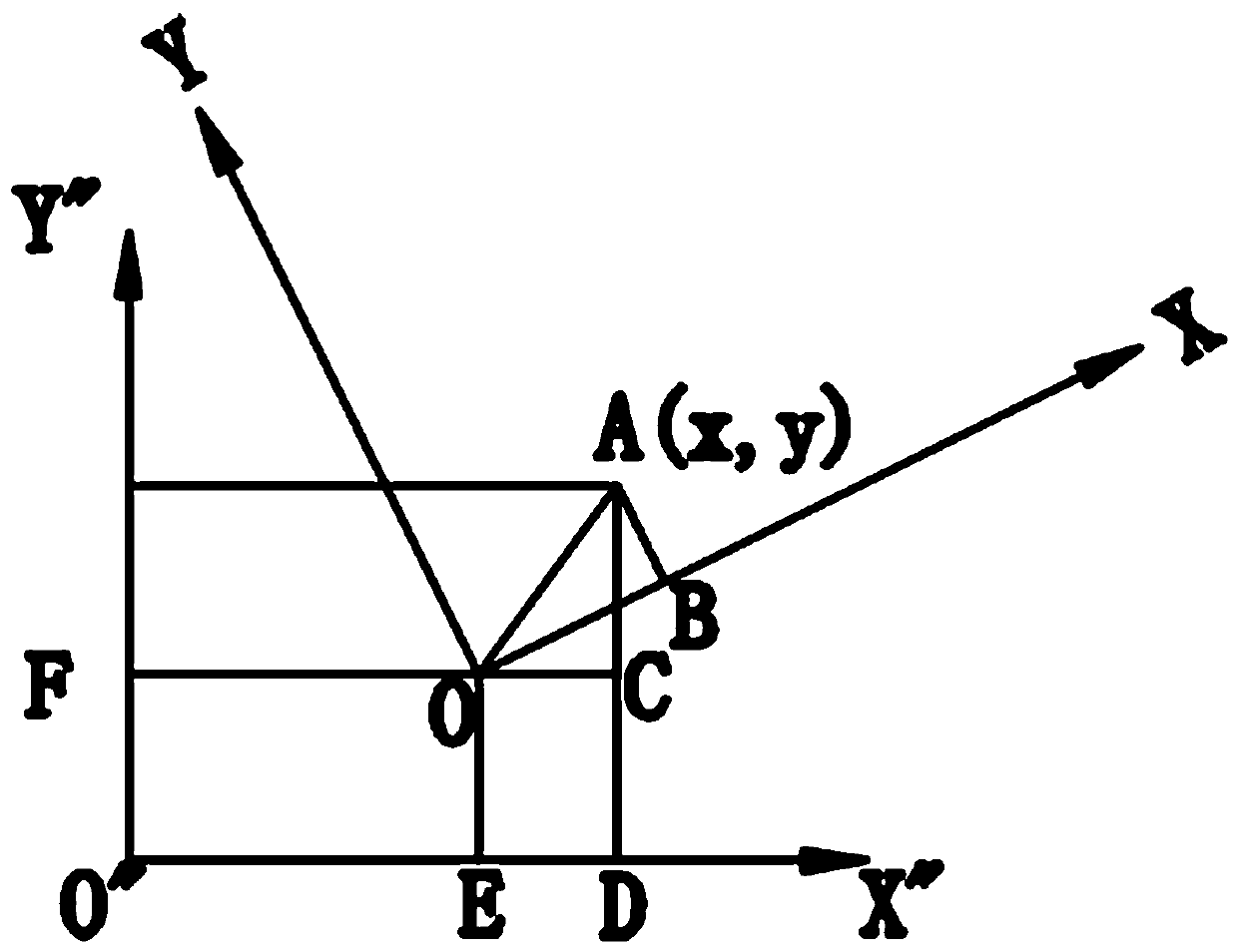

[0030] like Figure 1 to Figure 7 As shown, the specific embodiment of the present invention is as follows: the present invention is a method for accurately positioning incoming materials to a test box based on vision. The method of the present invention comprises the steps:

[0031] A. The product is transported to the feeding area of the feeding track 1, and the CCD camera 3 on the manipulator 2 takes pictures of the two characteristic points of the product;

[0032] B. The manipulator 2 adjusts the product through the rotation center compensation algorithm;

[0033] C. The manipulator 2 grabs the product, and then puts it on the transfer platform 4, and the manipulator 2 places 4 products in one batch in a row;

[0034] D. The manipulator 2 simultaneously sucks and transports the four products on the transfer platform 4 to the test box 5 in the test area.

[0035] Further, in step D, the number of test boxes 5 is 16, and the 16 test boxes 5 are evenly distributed on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com