A light transmittance precision detection mechanism

A detection mechanism and light transmittance technology, applied in transmittance measurement, testing optical performance and other directions, can solve the problems of light leakage, affect the detection accuracy, and the flatness is difficult to fit tightly, and achieve the effect of improving stability and reducing light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

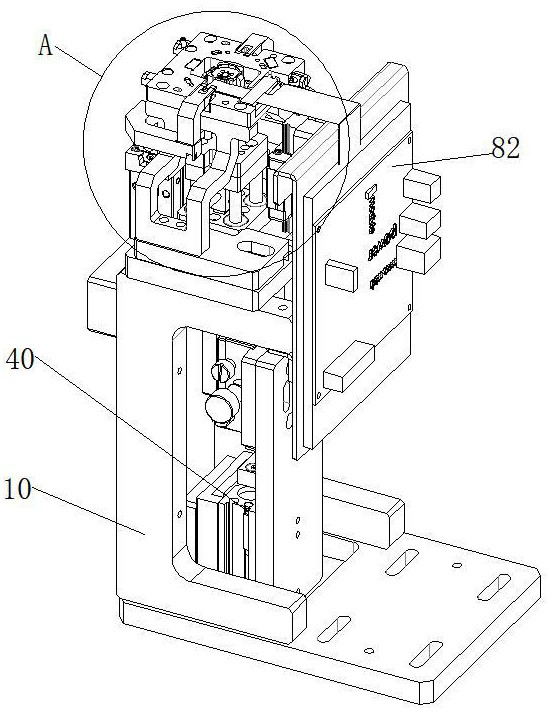

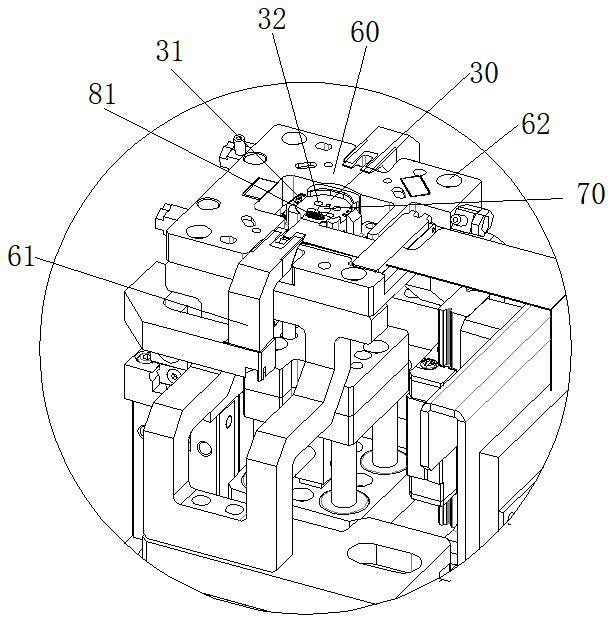

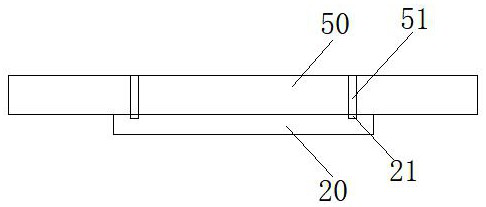

[0024] see Figure 1 to Figure 3 , as shown in the legend therein, a light transmittance precision detection mechanism includes a frame 10 and a detection system installed on the frame 10, the detection system includes a light source module 20 for emitting light, a light source module 20 for carrying The first jig 30 and the detection module used to detect the light transmittance, the first jig 30 is a floating jig, and the lower part of the first jig 30 is provided with a lifting drive device 40 for driving it up and down in the vertical direction, The outer periphery of the first jig 30 is provided with a second jig 60 for carrying the product 50 to be tested. The light source module 20 includes an upper surface and at least one light emitting portion 21 arranged on the upper surface. The product 50 to be tested includes a lower surface and a device. At least one light-transmitting portion 51 on the lower surface, when the product to be tested 50 and the light source module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com