Impact strength testing machine for axillary crutch

An impact strength and testing machine technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of complex impact methods, affecting the accuracy of impact performance testing of axillary crutches, and safety threats to test personnel, and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

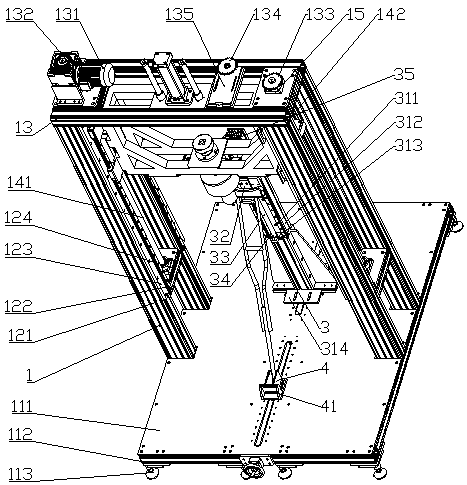

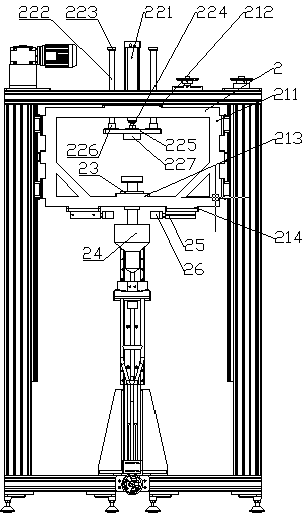

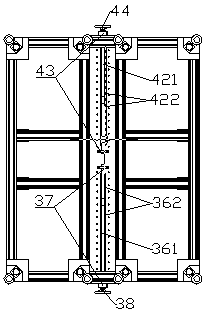

[0017] Preferred examples of the present invention are described as follows in conjunction with accompanying drawings:

[0018] Such as Figure 1 to Figure 3 As shown, a crutch impact strength testing machine includes a support 1, a frame mechanism for moving up and down 2, an armrest posture adjustment mechanism 3, a foot posture adjustment mechanism 4, a protective net and a control box; it is characterized in that: the upper and lower The left and right sides of the mobile frame 2 are fixedly connected with the T nuts connected to the two lead screws 141 and 142 between the bracket 1, the motor 131 is connected to the reducer 132, the extension shaft of the reducer 132 is connected to the active lead screw 141 through a coupling, and the drive The rod 141 drives the driven screw 142 to rotate synchronously through the transmission of the sprockets 133 and 134, thereby driving the up and down movement of the frame 2 including the weight 24 to move up and down, and the postur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com