Fretting wear test device and system

A fretting wear and test device technology, applied in the direction of applying repetitive force/pulsation force to test material strength and test wear resistance, can solve problems such as easy failure and unfavorable test, and achieve the effect of positive pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

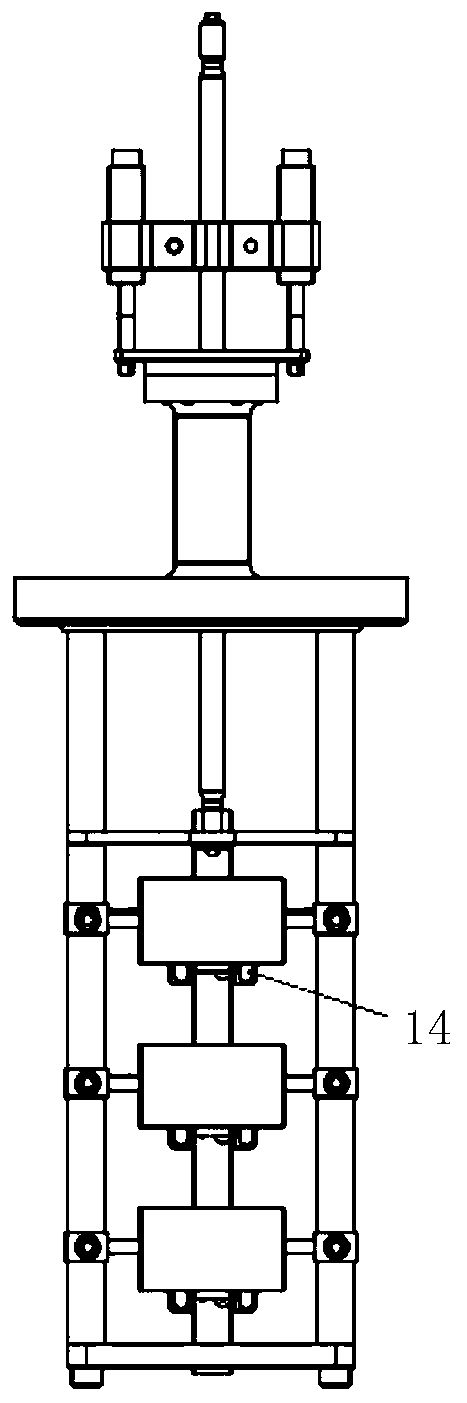

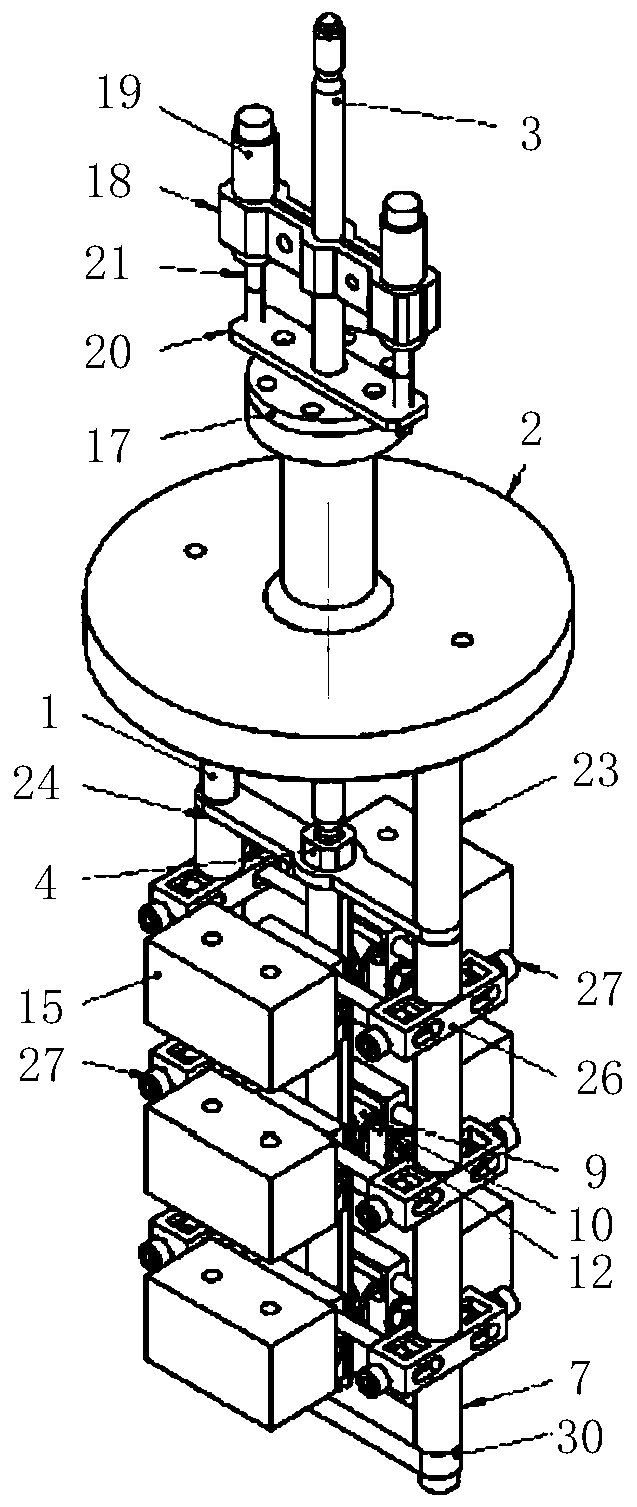

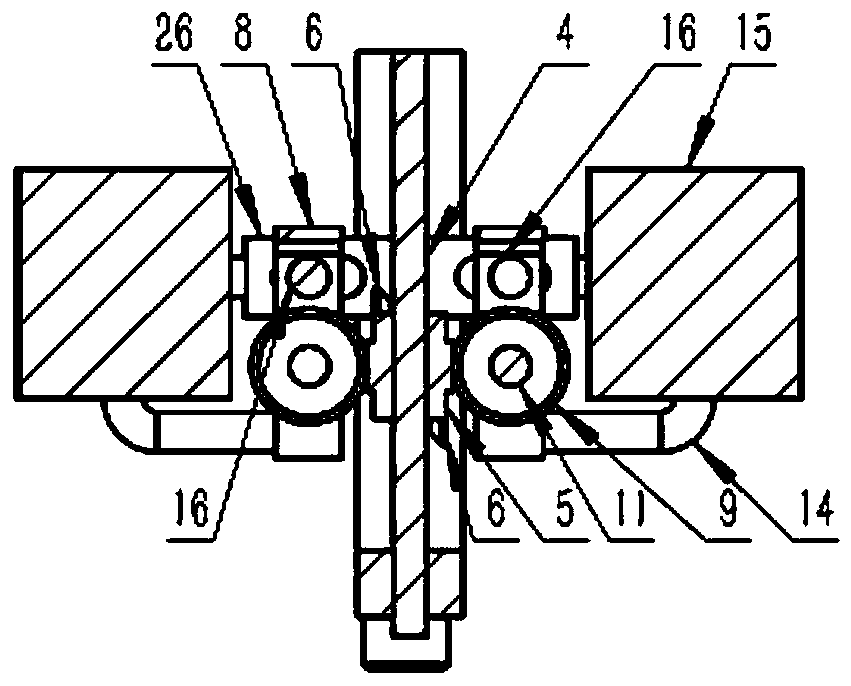

[0054] A tangential fretting wear test device for simulating the environment of a sodium-cooled reactor, including a container cover 2 of liquid sodium, through which the bolt 1 is fixed by the support, and the support 23 is fixed on the container cover 2 under the action of the positioning sleeve 7, and the upper moving head The positioning plate 24 and the lower moving head positioning plate 30 connect the two pillars 23 . The movement rod 3 runs through the container cover 2 of liquid sodium, and is connected by the movement head assembly 4 , the upper movement head positioning plate 24 and the lower movement head positioning plate 30 . The displacement measuring element is composed of LVDT chuck 18 , LVDT piece 19 and LVDT iron core 21 , wherein the LVDT chuck 18 is fixedly connected to the moving rod 3 , and the LVDT iron core 21 is fixedly connected through the fixed plate 20 and the sealing ring cover plate 17 . sports bar 3 and figure 2 The moving head assembly 4 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com