Connector welding test device

A test device and connector technology, applied in the field of testing, can solve problems such as time-consuming, poor welding, occupation of manpower and material resources, etc., and achieve the effect of saving maintenance costs, improving work efficiency, and reducing the time spent on measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

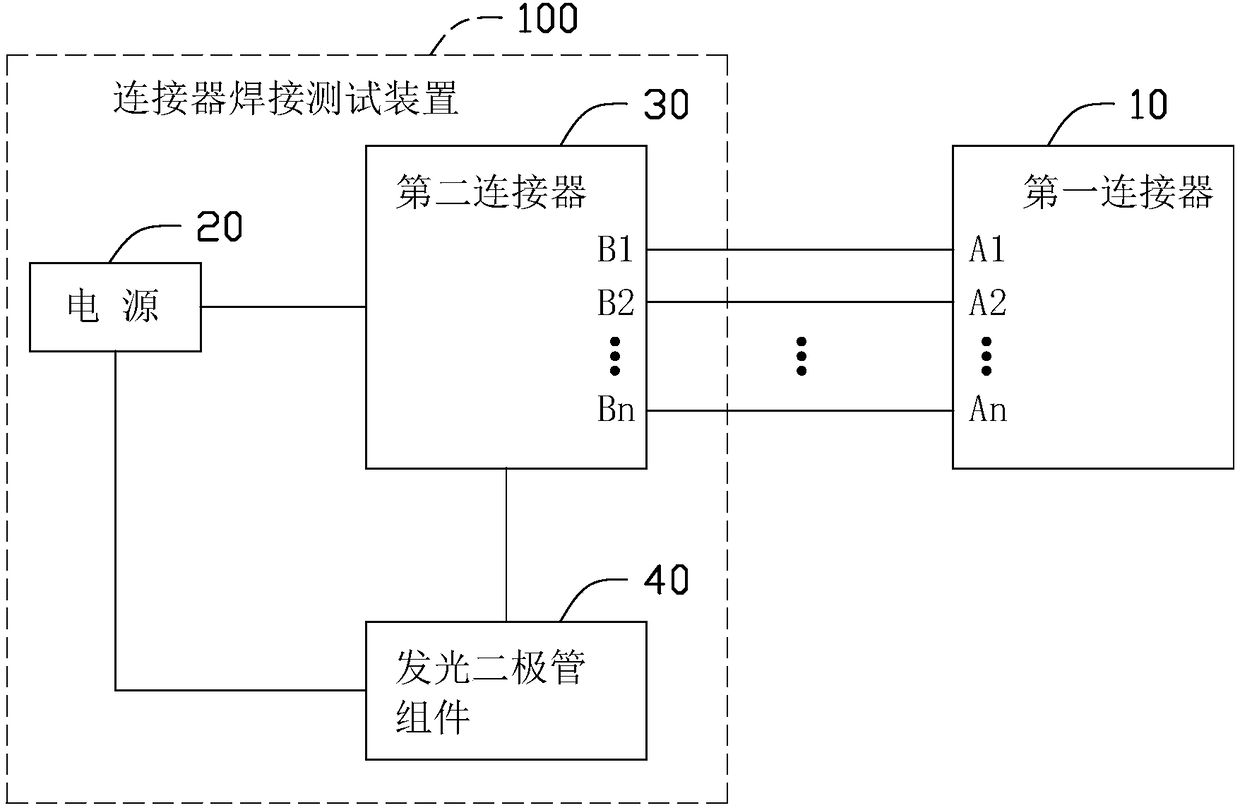

[0019] See Figure 1-3 An embodiment of the present invention provides a connector welding test device 100. The connector welding test device 100 can test the first connector 10 welded on the PCBA 200, which can be a notebook computer motherboard, a server motherboard, or the like.

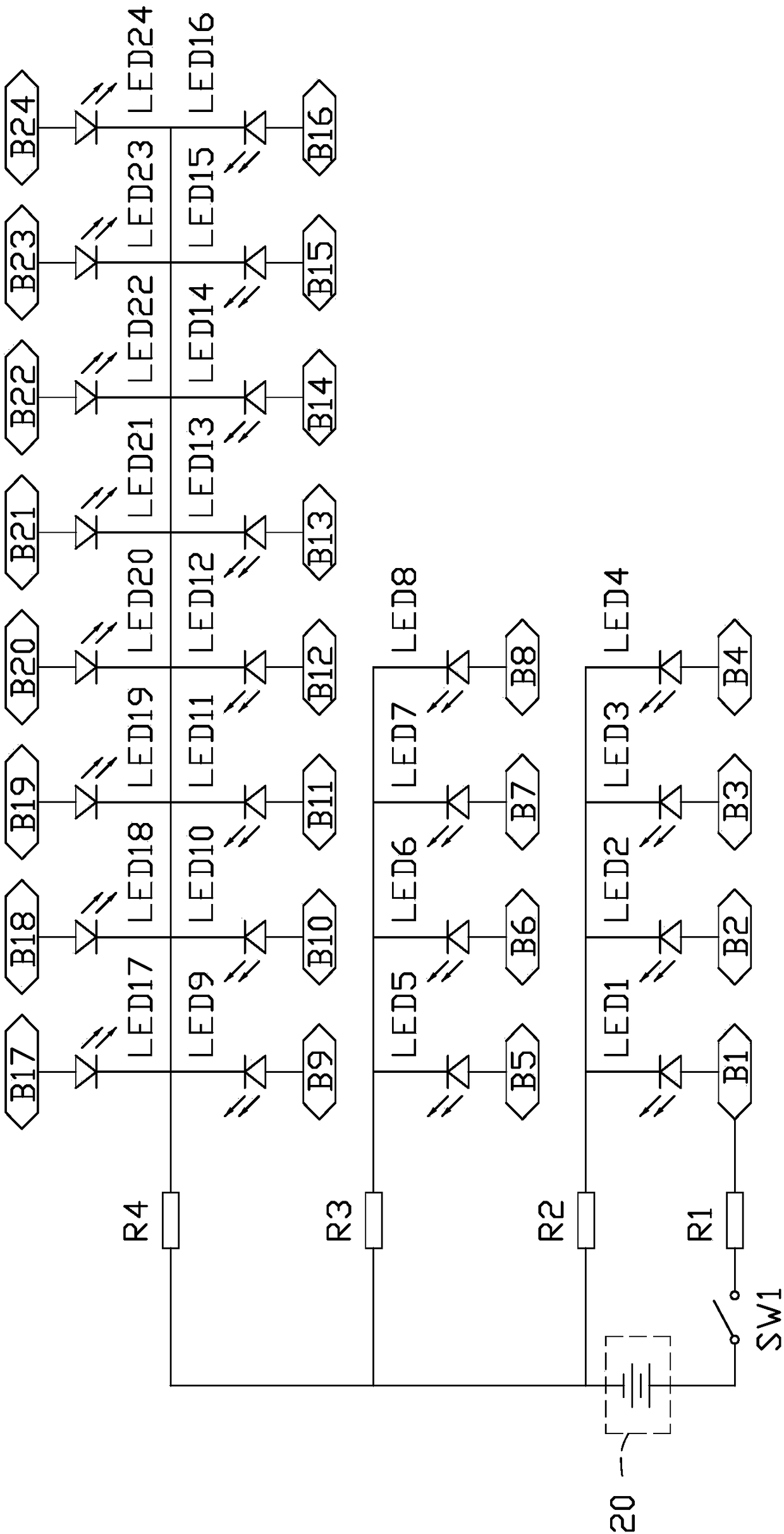

[0020] The connector welding test device 100 includes a power source 20, a second connector 30 and a light emitting diode assembly 40. The light-emitting diode assembly 40 includes a plurality of light-emitting diodes LED1-LEDm (m is an integer and m> 1). The second connector 30 is matched with the first connector 10 and can be inserted into each other. That is, the first connector 10 and the second connector 30 are preferably connectors of the same model, the first connector 10 is preferably a female connector, and the second connector 30 is preferably a male connector. The first connector 10 includes a plurality of pins A1 to An, and the second connector 30 includes a plurality of pins B1 to Bn. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap