A point cloud stitching method for flat parts based on multi-dimensional space invariant features

A point cloud stitching and multi-dimensional space technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of point cloud surface information less, poor operation flexibility, poor stability, etc., to avoid too few feature points and improve recognition , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with figures and examples.

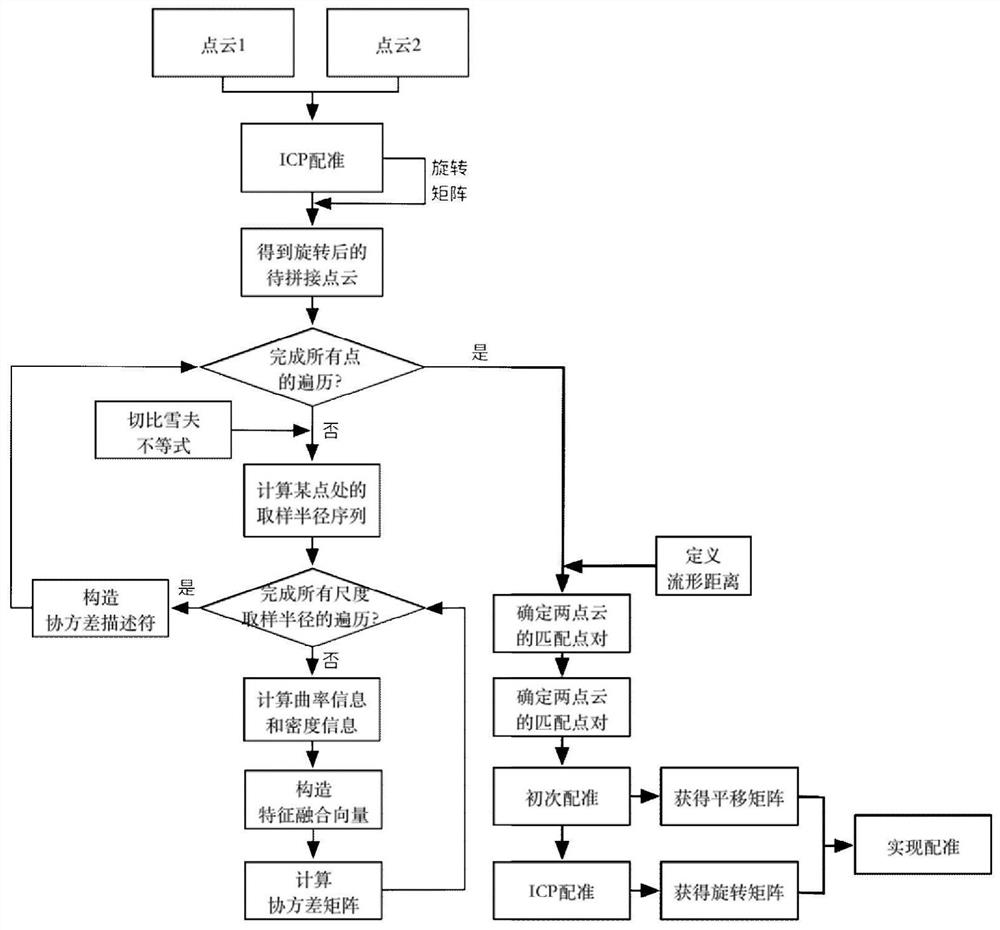

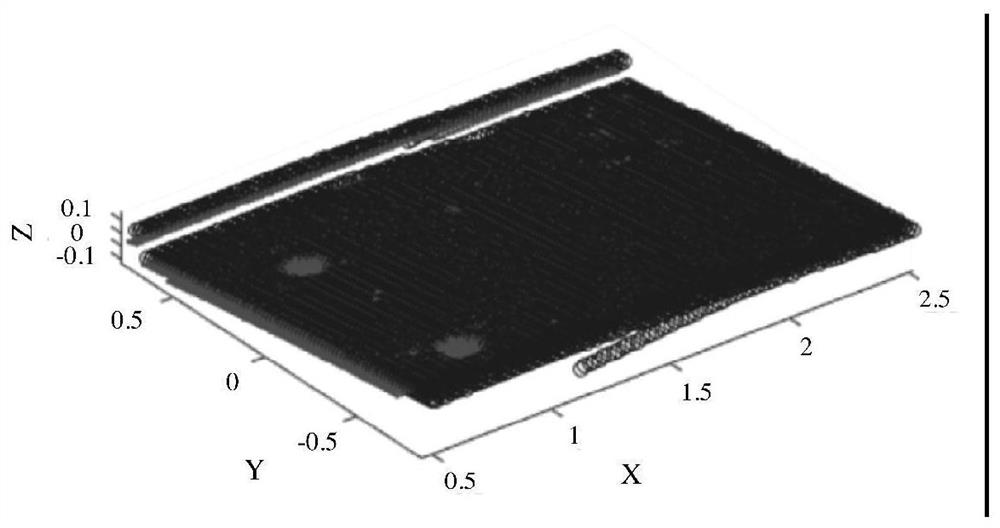

[0073] For the point clouds to be spliced of two plate-shaped mechanical parts with hole features, the embodiment implemented according to the complete method of the present invention adopts the following steps to splice:

[0074] Step 1: Use the nearest neighbor iterative algorithm to calculate the point cloud rotation matrix, and use the rotation matrix to transform the spatial position of the point cloud to be stitched, and use the transformed point cloud to provide an initial value for subsequent stitching. Thus, two initial point clouds are obtained, one of which is the point cloud to be stitched after space transformation, and the other initial point cloud is another point cloud to be stitched without space transformation.

[0075] The rotation matrix R obtained in step 1 1 for:

[0076]

[0077] Step 2: According to Chebyshev's inequality, under the premise of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com