Substrate mounting type coaxial connector and manufacturing method thereof

A technology for coaxial connectors and manufacturing methods, applied in the direction of connection, two-component connection devices, coupling devices, etc., can solve problems such as deterioration of electrical characteristics, and achieve the effect of suppressing the deterioration of electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

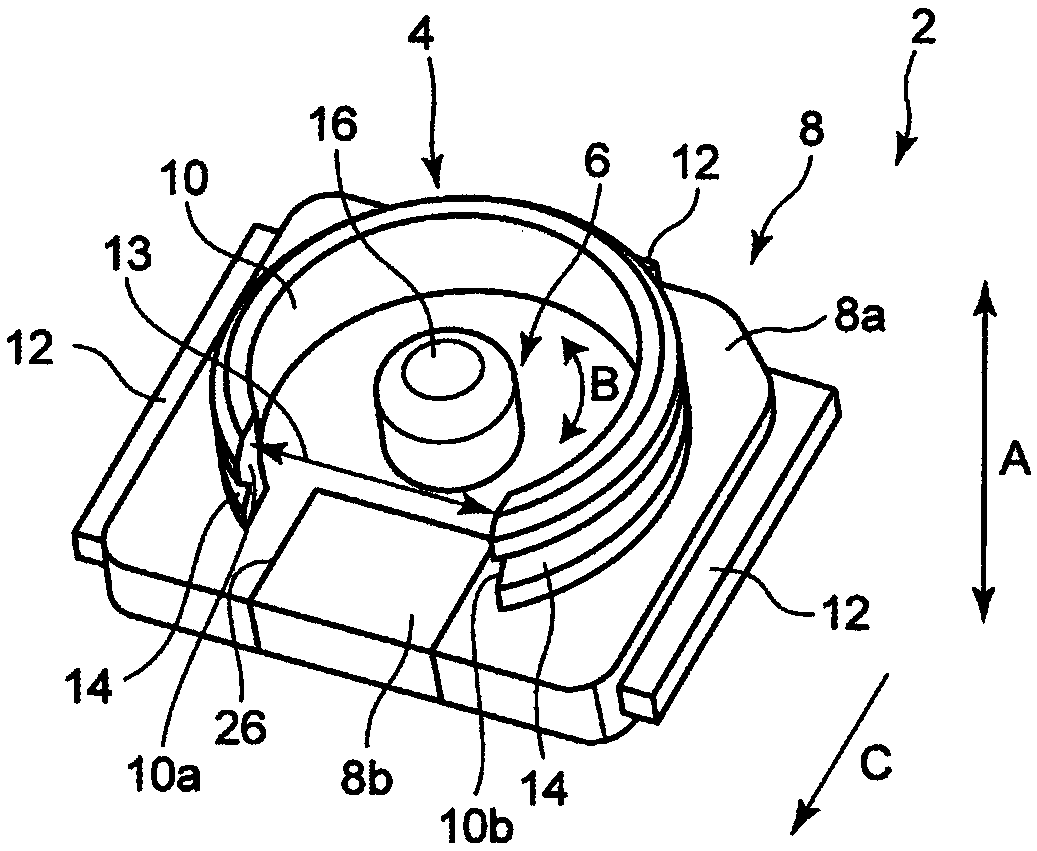

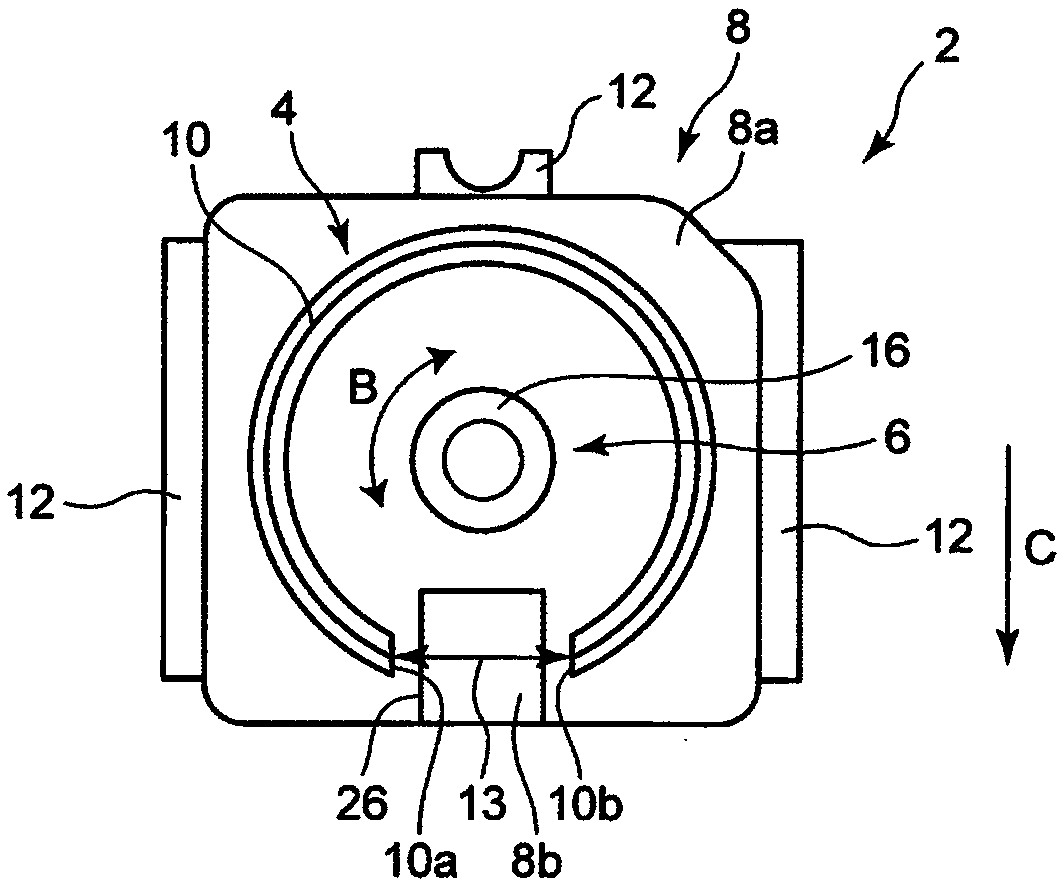

[0050] use Figure 1 ~ Figure 4 The schematic structure of the coaxial connector 2 in Embodiment 1 will be described. figure 1 Is a perspective view of the coaxial connector 2 of the first embodiment, figure 2 Is a top view of the coaxial connector 2, image 3 Is the rear view of the coaxial connector 2. Figure 4 It is an exploded perspective view of the coaxial connector 2 with the insulating member omitted.

[0051] The coaxial connector 2 in the first embodiment is mounted on the substrate 20 described later via the external terminal 4 and the internal terminal 6 ( Figure 5 ) Is a board-mounted coaxial connector (hereinafter simply referred to as "coaxial connector"). image 3 The shown coaxial connector 2 is mounted on the substrate 20 on the back side.

[0052] The coaxial connector 2 of the first embodiment is mounted on a mating connector (not shown) in a state of being mounted on the substrate 20. in particular, figure 1 , figure 2 The external terminal 4 and the intern...

Embodiment approach 2

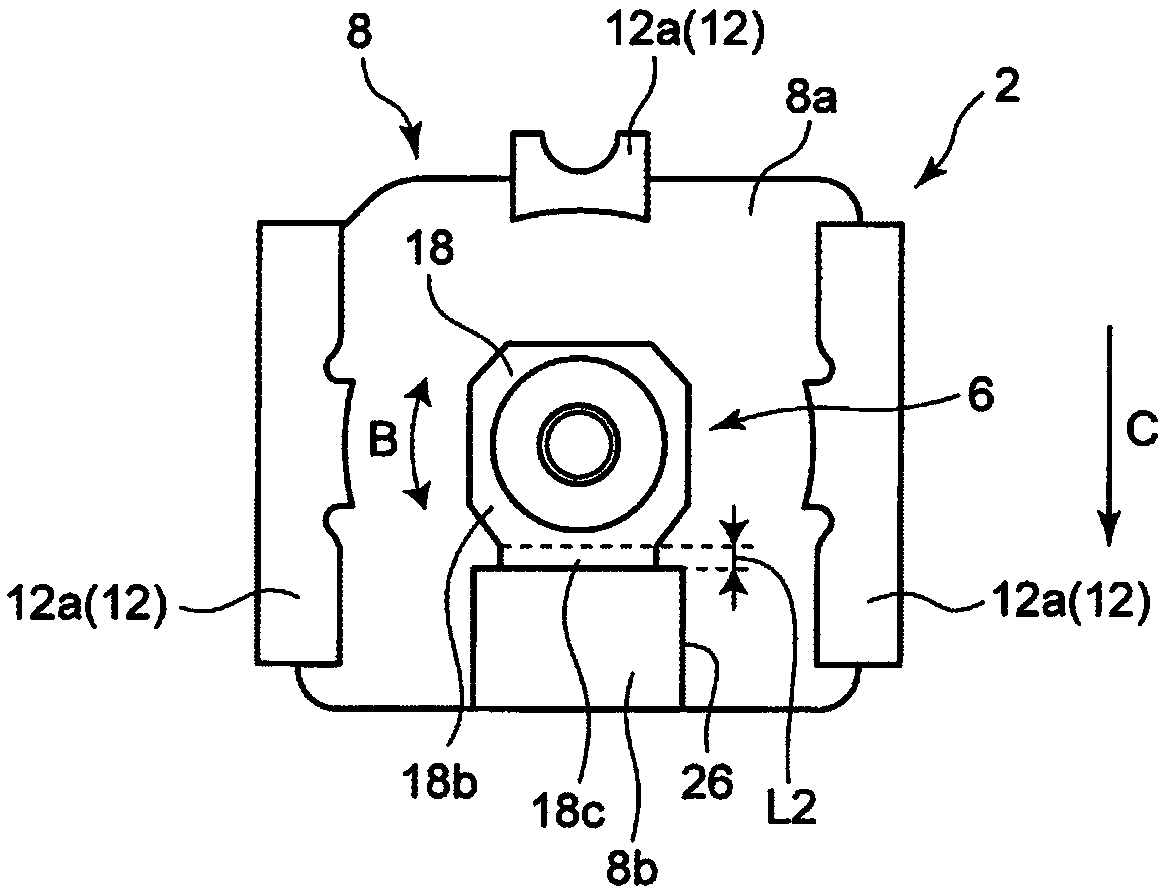

[0093] The coaxial connector and its manufacturing method according to Embodiment 2 of the present invention will be described. In addition, in the second embodiment, differences from the first embodiment will be mainly described. In addition, the same or equivalent configuration as that of the first embodiment will be described with the same reference numerals.

[0094] In Embodiment 1, when viewed from the A direction, the external conductor portion 10 of the external terminal 4 has a cylindrical partial shape interrupted in the B direction. In contrast, in Embodiment 2, the external conductor portion of the external terminal is It is different from the first embodiment in a complete cylindrical shape connected in the circumferential direction.

[0095] in Figure 7 ~ Figure 9 The coaxial connector 30 in Embodiment 2 is shown in FIG. Figure 7 Is a perspective view of the coaxial connector 30 of the second embodiment, Figure 8 Is a top view of the coaxial connector 30, Pictur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com