Electrooptic device, manufacturing method thereof, liquid crystal device and projective display device

A technology of electro-optic devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, electrical components, etc., can solve problems such as smaller aperture ratio, difficulty in improving pixel integration, charge leakage, etc., to prevent excessive current carrying The effect of suppressing the accumulation of sub-substrates, suppressing the floating effect of the substrate, and preventing the flow of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Refer below Figure 1 to Figure 8 An embodiment of the present invention will be described.

[0065] In this embodiment, as an example of the electro-optical device of the present invention, an example of a liquid crystal light valve (liquid crystal device) used as a light modulation device of a projection display device will be described. The liquid crystal light valve of this embodiment is an active matrix mode liquid crystal panel, and an SOQ substrate is used on the element substrate side.

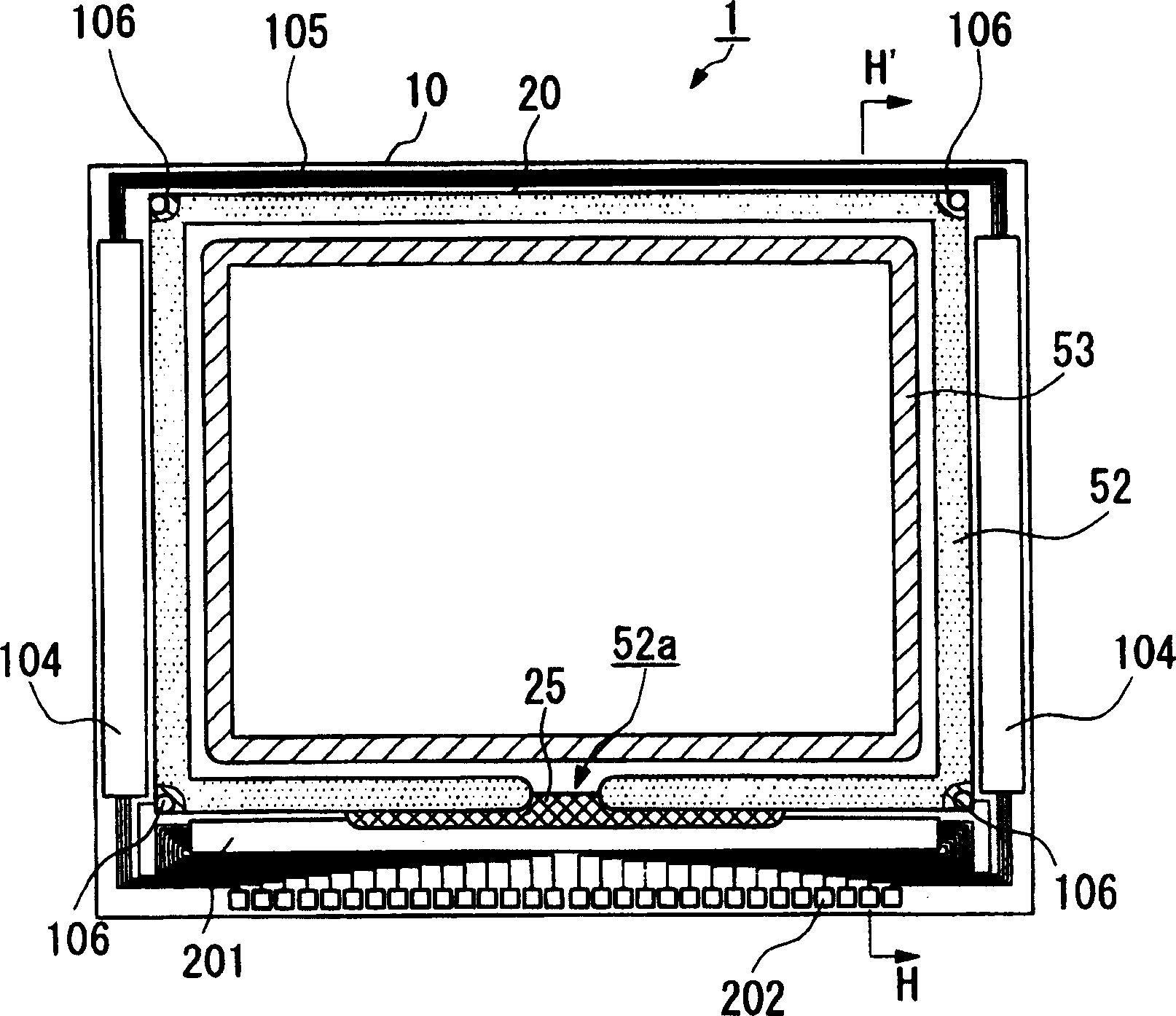

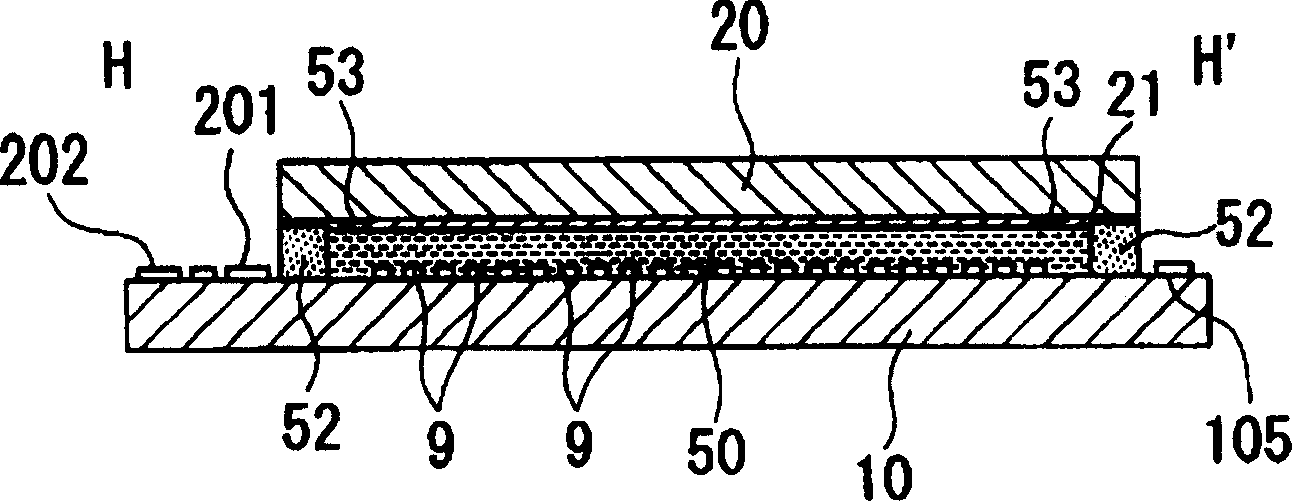

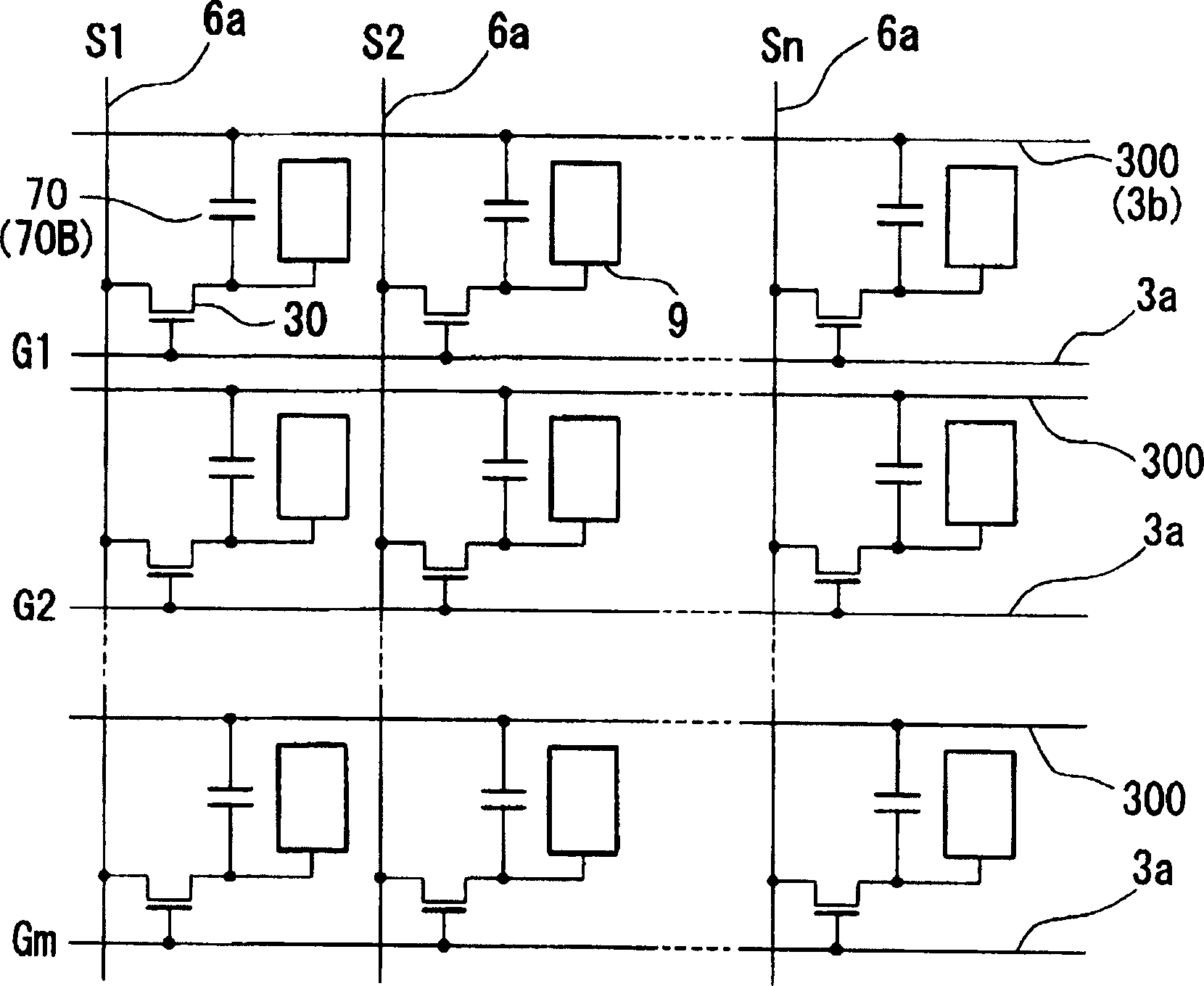

[0066] figure 1 is a schematic configuration diagram of a liquid crystal light valve as an example of the electro-optic device of the present invention, figure 2 is along figure 1 The profile of the H-H' line, image 3 It is an equivalent circuit diagram of a plurality of pixels forming a matrix to form a liquid crystal light valve, Figure 4 is the planar view of multiple pixel groups, Figure 5 is along Figure 4 The profile of the line A-A', Figure 6 It is a cross-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com