Nicu alloy target and laminated film for cu electrode protective film

A technology of electrode protective film and alloy target, which is applied in the field of NiCu alloy target and laminated film for Cu electrode protective film, which can solve the problems of low magnetic permeability of the target material and no one has raised the problem of Cu electrode protective film, so as to achieve effective sputtering , The effect of suppressing the deterioration of electrical characteristics and improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] [1. Preparation of sample]

[0145] A Ni-Cu-Cr alloy target with a predetermined composition is prepared by a dissolution casting method. The Cu content is set to 10 to 60% by mass. The Cr content is set to 0 to 11% by mass. In addition, a Ni-35mass%Cu-1.5mass%Cr-1.5mass%Ti alloy target was prepared by a dissolution casting method. Further, pure Cu and ITO were used for comparison.

[0146] [2. Test method]

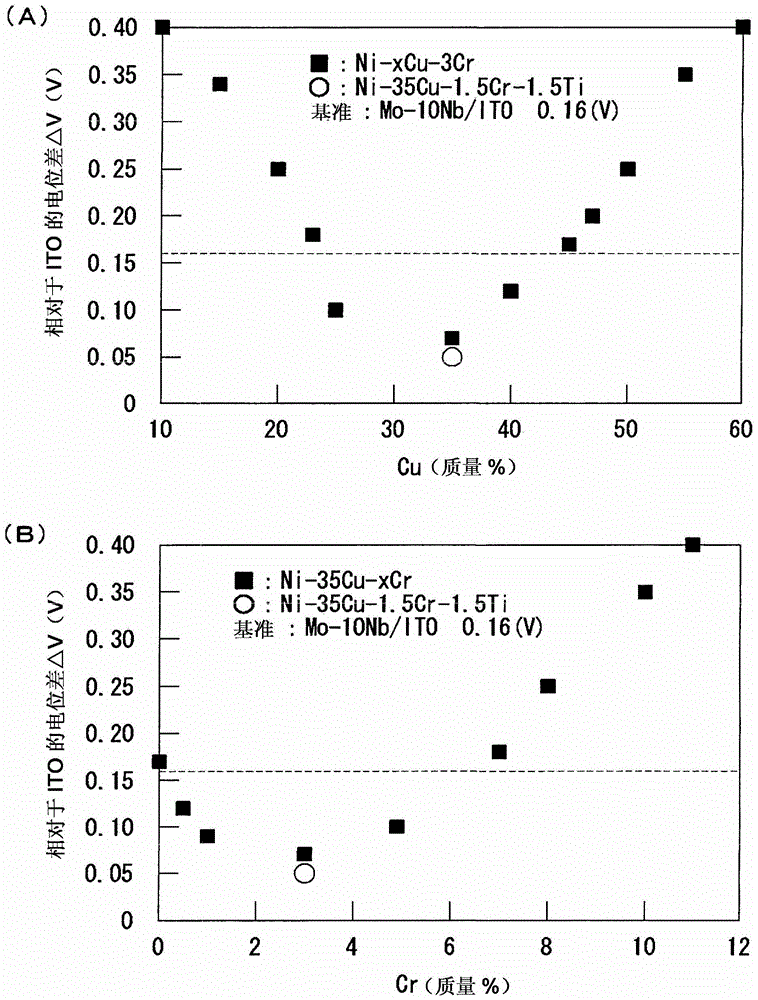

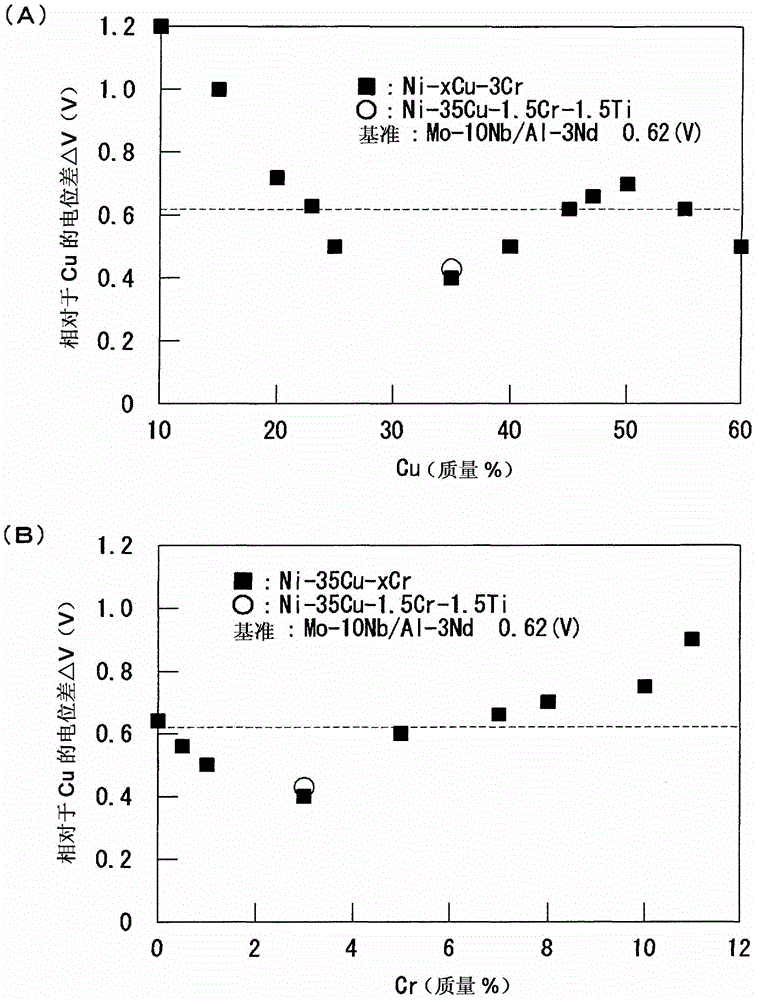

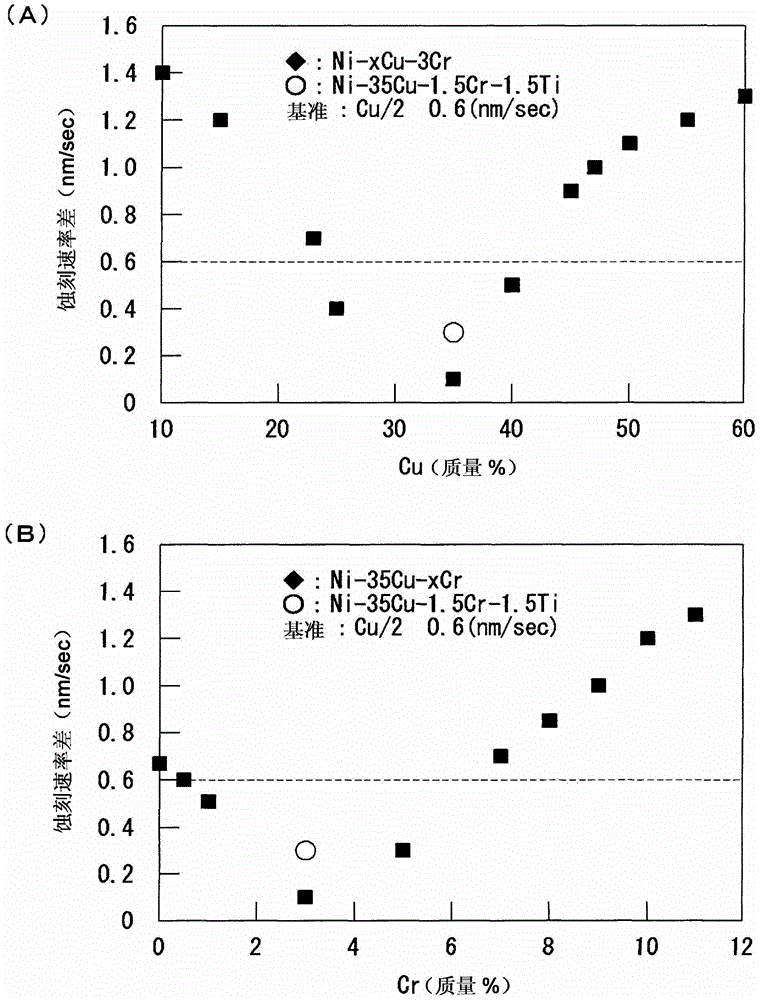

[0147] [2.1. Potential difference]

[0148] The standard potentials of Ni-Cu-Cr alloy, Ni-Cu-Cr-Ti alloy, Cu and ITO were measured respectively. Using a carbon electrode as a counter electrode and a calomel electrode as a reference electrode, the standard potential was measured using a potentiostat method in a 200 g / L ammonium sulfate aqueous solution maintained at 40°C.

[0149] Using the obtained standard potential of each material, calculate the potential difference ΔV (V) between Ni-Cu-Cr alloy or Ni-Cu-Cr-Ti alloy and Cu, and the potential difference bet...

Embodiment 2

[0203] [1. Preparation of sample]

[0204] A Ni-Cu-Ti alloy target with a predetermined composition is prepared by a dissolution casting method. The Cu content is set to 10 to 60% by mass. The Ti content is set to 0 to 7% by mass. In addition, as a comparison, pure Cu and ITO were used.

[0205] [2. Test method]

[0206] According to the same procedure as Example 1, the potential difference ΔV between Ni-Cu-Ti alloy and Cu, the potential difference ΔV between Ni-Cu-Ti alloy and ITO, the potential difference ΔV between Ni-Cu-Ti alloy and Cu, The etch rate difference, the stripping rate, and the maximum magnetic permeability μ.

[0207] [3. Results]

[0208] [3.1. Potential difference △V]

[0209] Figure 9 The potential difference ΔV between Ni-Cu-Ti alloy and ITO is shown in . Figure 9 , the dotted line indicates the potential difference ΔV (0.16 V) between Mo-10Nb and ITO used as a protective film for Al-based wiring material in the prior art.

[0210] Figure 10 T...

Embodiment 3

[0249] [1. Preparation of sample]

[0250] Using the target prepared in Example 1 or 2, a laminated film for a touch panel was prepared. That is, a barrier layer, an electrode layer, and a cover layer are sequentially formed (from bottom to top) on the surface of the substrate by sputtering. As the substrate, an ITO / underlayer film / PET substrate or an ITO / underlayer film / glass substrate (both commercially available) was used. A NiCu alloy containing a predetermined amount of Cu or Ti was used for the barrier layer and the cover layer, respectively, and Cu(5N) was used for the electrode layer.

[0251] For comparison, a laminated film was prepared in which Mo-10Nb alloy was used in the barrier layer and the cover layer, respectively, and Al-3Nd was used in the electrode layer.

[0252] Table 1 shows the film-forming conditions of the laminated film for touch panels.

[0253] Table 1

[0254] material power gas sputtering rate film thickness NiCu alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com