A cable penetration structure embedded in a composite shell

A composite material and shell technology, applied in electrical components and other directions, can solve the problems affecting the aerodynamic shape of the projectile, and achieve the effects of excellent erosion resistance, stable performance and reduced bending radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

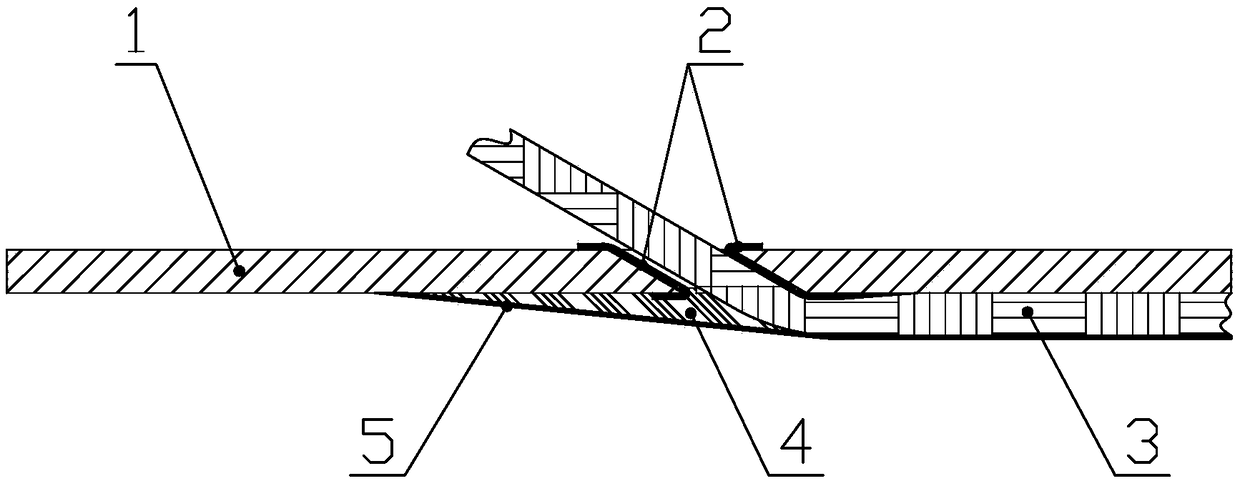

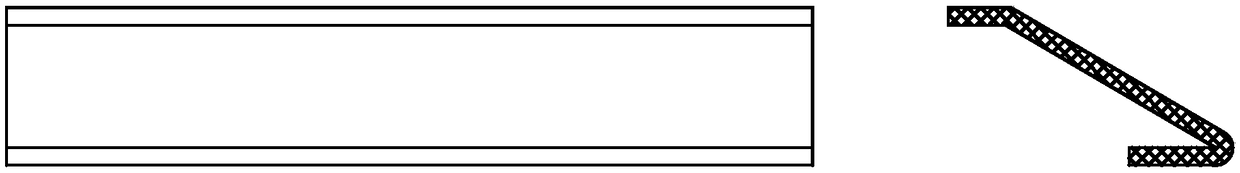

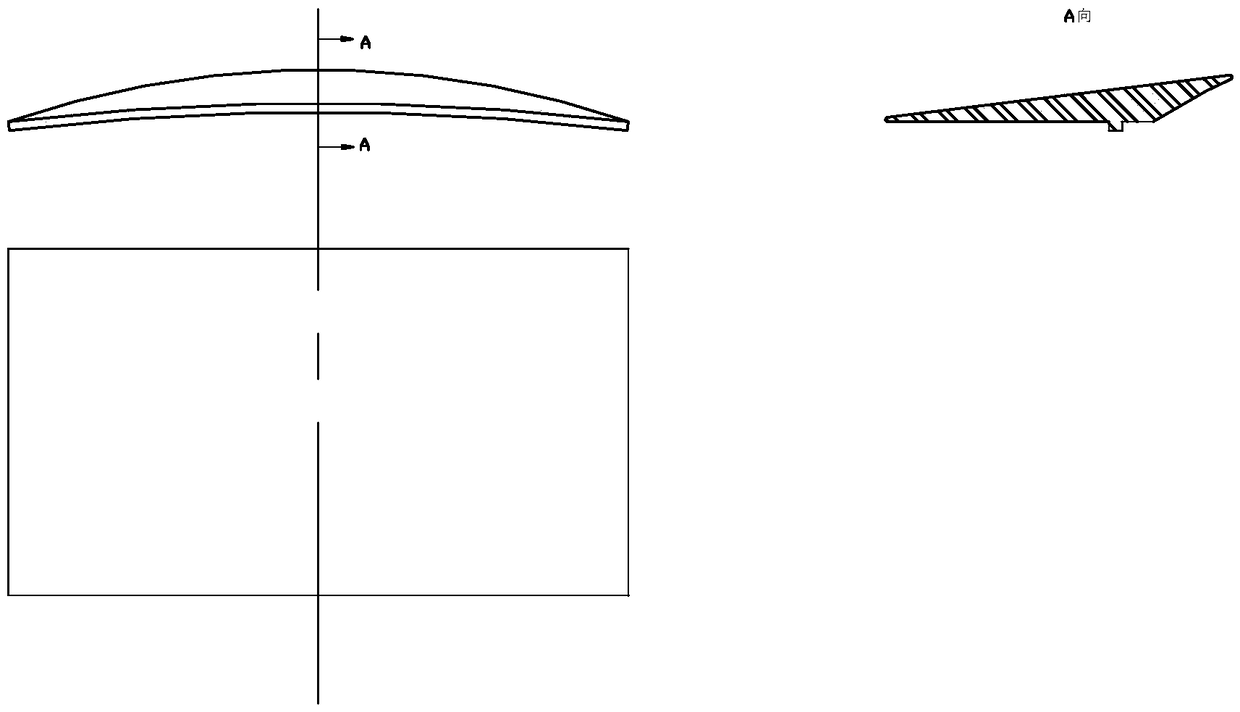

[0025] The invention provides a cable penetration structure embedded in a composite material shell, such as figure 1 As shown, it includes through-hole wear-resistant parts 2, a fairing 4 and a fiber fixing part 5; the peripheral parts include a composite material shell 1 and a cable 3.

[0026] Composite material housing 1 has oblique holes, and the embedded cable hole structure is designed as oblique hole type according to the number of cable cores. The angle of the oblique hole in the embodiment is 30°, which can minimize the local protrusion of the cable 3 caused by the transition of the bending radius, thereby strengthening the damage to the projectile by aerodynamic heating. If the angle of the inclined hole is greater than 60°, the aperture of the inclined hole can also be increased, so that the cable 3 does not need to pass into the cabin along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axis angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com