Display module

A display module and display area technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of large width of the lower border area, large occupied border width, and difficulty in realizing narrow borders for OLED display panels, so as to reduce bending Radius, improve bending performance, ensure normal display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

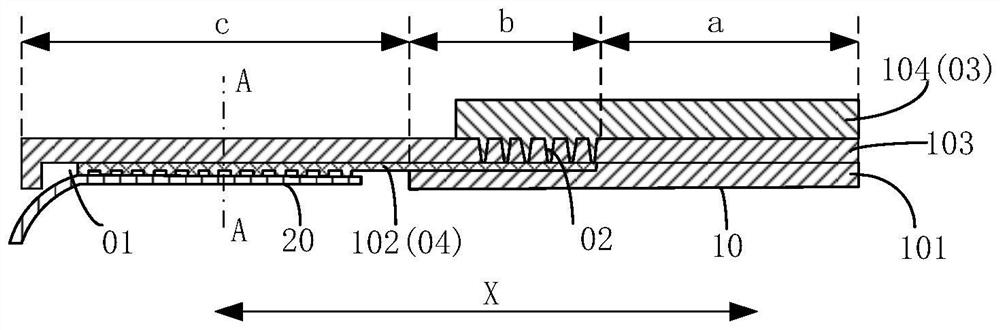

[0025] figure 1 This is a first structural schematic diagram of the display module provided in the first embodiment of the present application. refer to figure 1 , the present application provides a display module, the display module includes a display panel 10, the display panel 10 has a display area a, a bending area c, and a wiring between the display area a and the bending area c Region b, the display panel 10 includes a first substrate 101, a conductive layer 102, a second substrate 103 and a driving circuit layer 104 that are stacked in sequence, wherein the first substrate 101 is in the bending region c A gap 01 is formed, the second substrate 103 is provided with a via hole 02 in the wiring area b, and the driving circuit layer 104 includes a signal line 03 extending from the display area a to the wiring area b , the conductive layer 102 includes a connecting line 04 extending from the bending region c to the routing region b, one end of the connecting line 04 is exp...

Embodiment 2

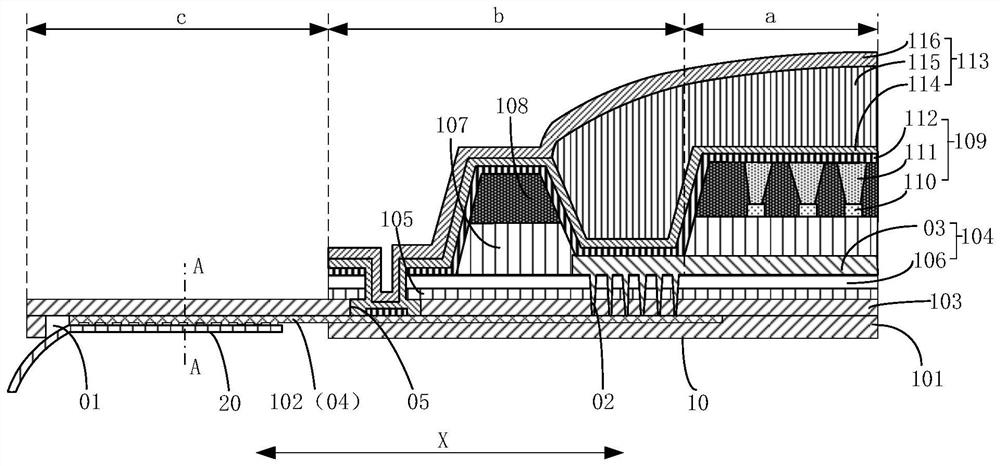

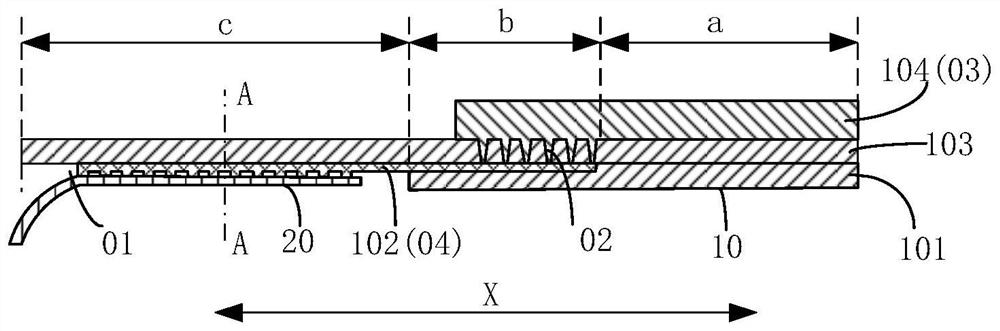

[0044] image 3 A first structural schematic diagram of the display module provided in the second embodiment of the present application; Figure 4 This is a second structural schematic diagram of the display module provided in the second embodiment of the present application. combine image 3 and Figure 4 As shown, the second embodiment of the present application provides a display module, the display module includes a first substrate 101, a conductive layer 102, a second substrate 103, a buffer layer 105, a driving circuit layer 104, The flat layer 107, and the pixel definition layer 108, the pixel unit 109 and the encapsulation layer 113 disposed on the flat layer 107, wherein the first substrate 101 is formed with a notch 01 in the bending region c, the The second substrate 103 is provided with a via hole 02 in the wiring area b, the driving circuit layer 104 includes the signal line 03 extending from the display area a to the wiring area b, and the conductive layer 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com